Luminous color variable upconversion nanometer luminescent material as well as preparation method and application thereof

A nano-luminescent material and luminescent color technology, applied in luminescent materials, color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of damaged nanoparticles, cumbersome, impure luminescent color, etc., and achieve the effect that is difficult to imitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

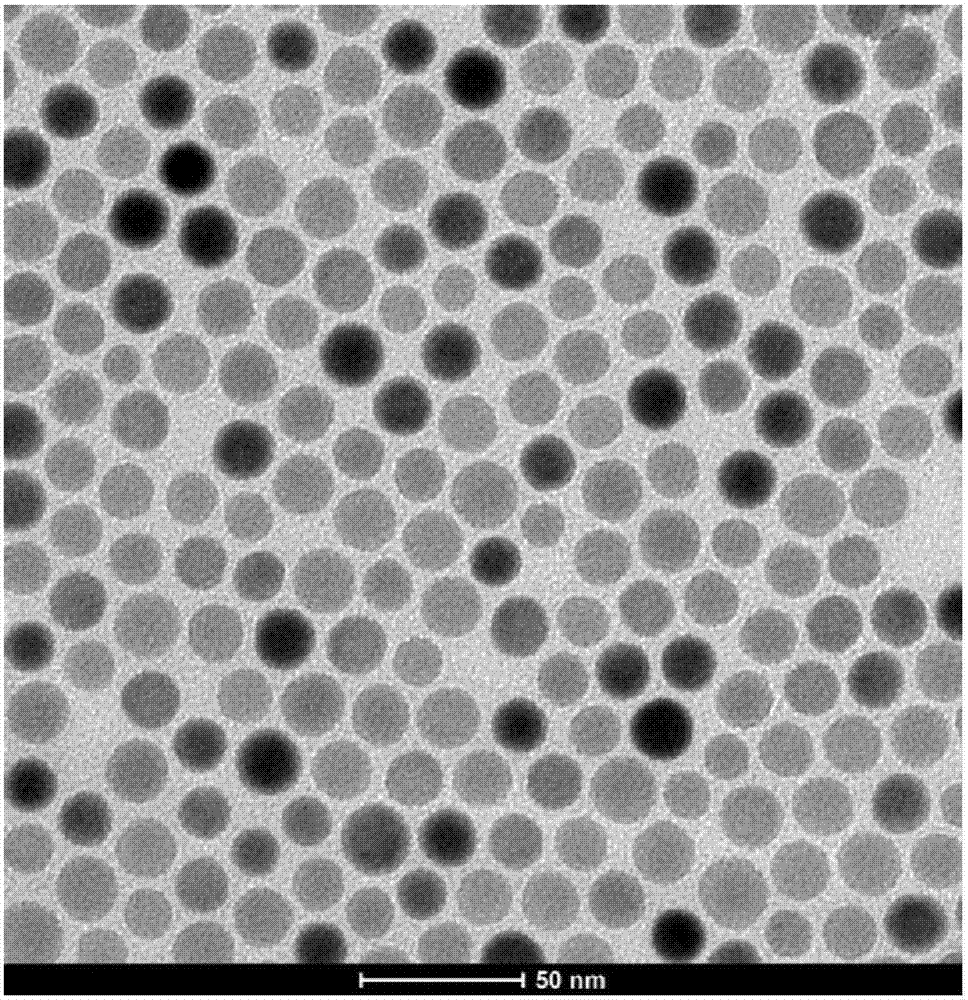

[0034] Preparation of core-shell NaGd by pyrolysis 0.79 f 4 :Yb 0.2 ,Tm 0.01 @NaGd 0.79 f 4 :Yb 0.2 ,Ho 0.01 Up-conversion nano-luminescent particles, the process is as follows:

[0035] 1mmol rare earth acetate salt Ln(CH 3 COO) 3 (Ln=Gd 3+ ,Yb 3+ ,Tm 3+ (molar ratio Gd 3+ :Yb 3+ :Tm 3+ =79:20:1)) dissolved in a mixed solution of 10mL oleic acid and 15mL 1-octadecene, heated to 110°C and stirred for 30min to form a transparent and uniform solution; after the above mixed solution was cooled to 50°C, NH 4 The methanol solution of F and the methanol solution of NaOH were stirred for about 30 minutes, the methanol in the solution was removed, the temperature of the solution was raised to 290°C and reacted for 90 minutes, and after cooling to room temperature, centrifugal cleaning was performed to obtain the nuclear structure NaGd 0.79 f 4 :Yb 0.2 ,Tm 0.01 Upconverting nanoparticles. Among them, NH 4 F. The molar ratios of NaOH to rare earth acetate are 4:1 and...

Embodiment 2

[0042] Preparation of core-shell NaGd by pyrolysis 0.79 f 4 :Yb 0.2 ,Ho 0.01 @NaGd 0.79 f 4 :Yb 0.2 ,Tm 0.01 Up-conversion nano-luminescent particles, the process is as follows:

[0043] 1mmol rare earth acetate salt Ln(CH 3 COO) 3 (Ln=Gd 3+ ,Yb 3+ ,Ho 3+ (molar ratio Gd 3+ :Yb 3+ :Ho 3+ =79:20:1)) dissolved in a mixed solution of 10mL oleic acid and 15mL 1-octadecene, heated to 110°C and stirred for 30min to form a transparent and uniform solution; after the above mixed solution was cooled to 50°C, NH 4 The methanol solution of F and the methanol solution of NaOH were stirred for about 30 minutes, the methanol in the solution was removed, the temperature of the solution was raised to 290°C and reacted for 90 minutes, and after cooling to room temperature, centrifugal cleaning was performed to obtain the nuclear structure NaGd 0.79 f 4 :Yb 0.2 ,Ho 0.01 Upconverting nanoparticles. Among them, NH 4 F. The molar ratios of NaOH to rare earth acetate are 4:1 and...

Embodiment 3

[0047] Preparation of core-shell NaGd by pyrolysis0.64 Ce 0.15 f 4 :Yb 0.2 ,Ho 0.01 @NaGd 0.79 f 4 :Yb 0.2 ,Tm 0.01 Up-conversion nano-luminescent particles, the process is as follows:

[0048] 1mmol rare earth acetate salt Ln(CH 3 COO) 3 (Ln=Gd 3+ , Ce 3+ ,Yb 3+ ,Ho 3+ (molar ratio Gd 3+ : Ce 3+ :Yb 3 + :Ho 3+ =64:15:20:1)) Dissolve in a mixed solution of 10mL oleic acid and 15mL 1-octadecene, heat to 110°C and stir for 30min to form a transparent and uniform solution; when the above mixed solution is cooled to 50°C, add NH 4 The methanol solution of F and the methanol solution of NaOH were stirred for about 30 minutes, the methanol in the solution was removed, the temperature of the solution was raised to 290°C and reacted for 90 minutes, and after cooling to room temperature, centrifugal cleaning was performed to obtain the nuclear structure NaGd 0.64 Ce 0.15 f 4 :Yb 0.2 ,Ho 0.01 Upconverting nanoparticles. Among them, NH 4 F. The molar ratios of Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com