Fan, Impeller thereof, method of balancing weight of the impeller, and impeller balancing system

A fan wheel and counterweight technology, which is applied to other household appliances, parts of pumping devices for elastic fluids, material gluing, etc., can solve the problem of inapplicable and unsuitable thin fans, and the counterweight of the fan wheel 9 cannot be used Balance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the following is based on preferred embodiments of the present invention, and is described in detail as follows in conjunction with the attached drawings:

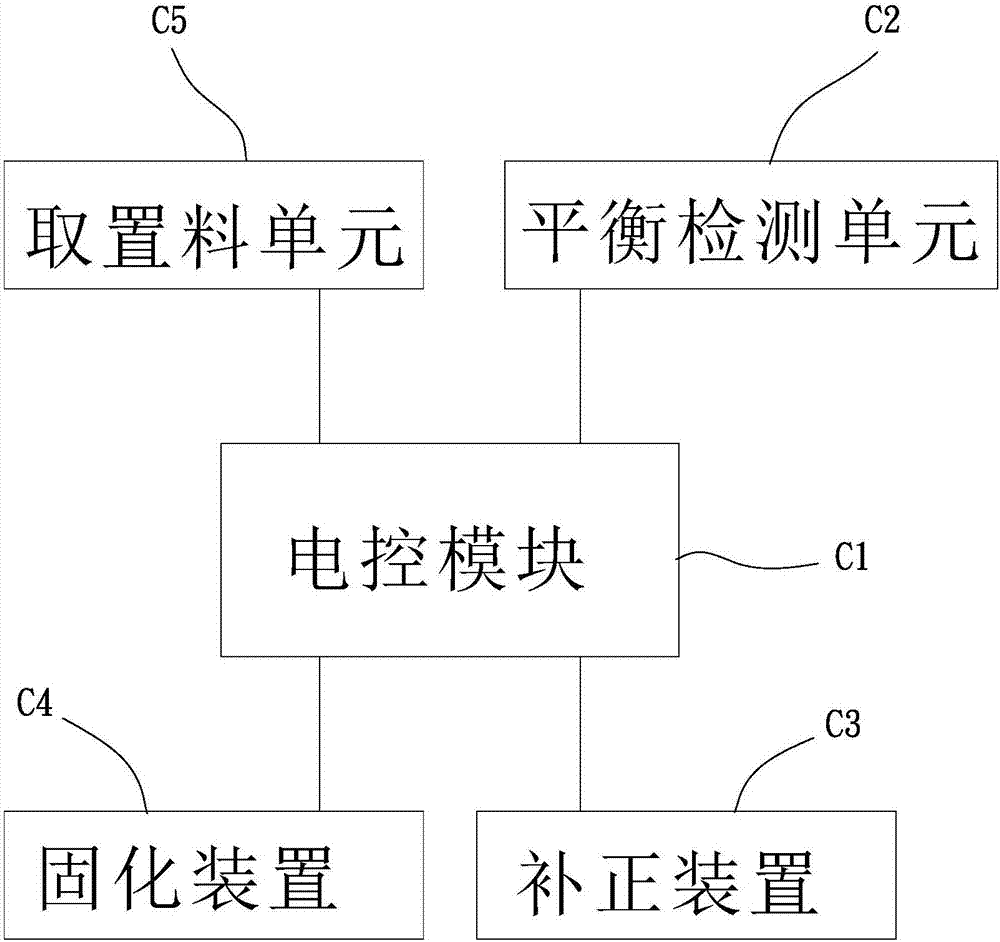

[0086] Please refer to figure 2As shown, in an embodiment of the method for balancing the fan wheel counterweight of the present invention, a fan wheel counterweight balancing system can be used to implement, and the fan wheel counterweight balancing system includes: an electronic control module C1, a balance detection unit C2 , a correction device C3 and a curing device C4. The electronic control module C1 is respectively coupled to the balance detection unit C2, the correction device C3 and the curing device C4. The electronic control module C1 can be a computer host, workstation or microcontroller unit (microcontroller unit, MCU) and other equipment with computing functions, and the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com