Experimental coal rock sample rapid-accurate machining device and method

A processing device and technology for coal and rock samples, applied in the field of mining machinery, can solve the problems of wasting coal and rock test blocks, difficult to take out complete samples, reducing experimental efficiency, etc., and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

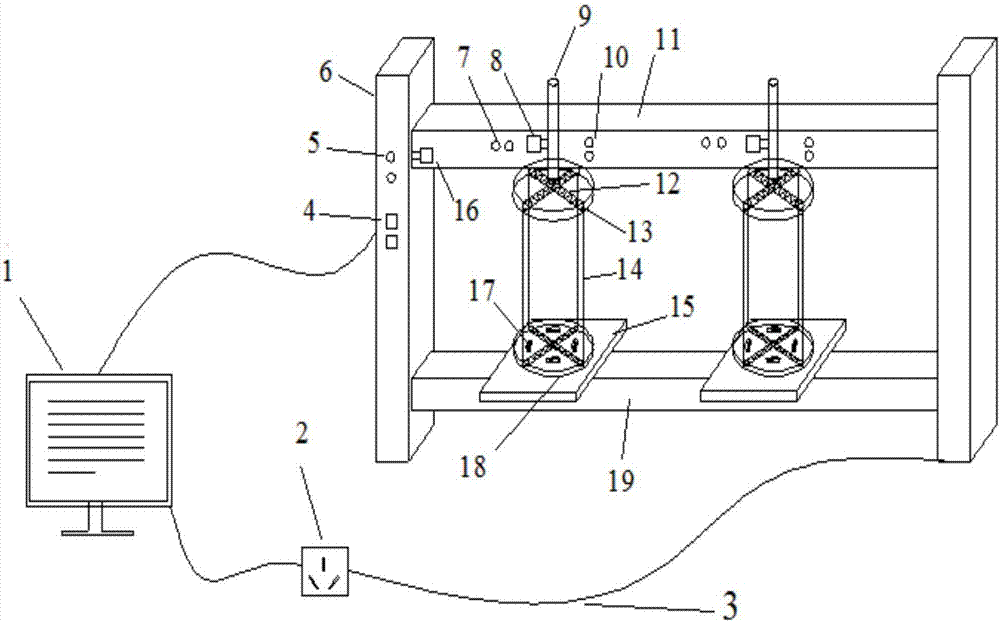

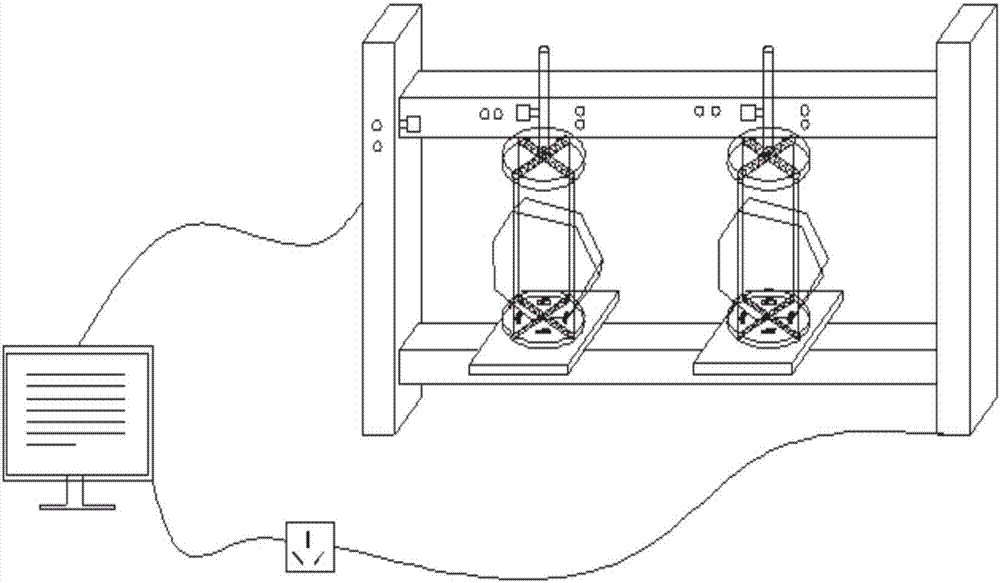

[0022] Such as figure 1 , figure 2 As shown, a fast and precise processing device for experimental coal and rock samples includes a server 1, a power supply 2, a data line 3, a main switch for controlling the processing device 4, a button 5 for controlling the movement of the upper joist, a vertical arm 6, and a control button 7 for a rotating motor. Rotary motor 8, drive shaft 9, saw arm control button 10, upper joist 11, saw arm 12, pulley 13, wire saw 14, tray 15, travel motor 16, drive wheel 17, detent 18, lower joist 19.

[0023] The control signals of the moving motor 16 and the rotating motor 8 are respectively transmitted by the server 1 through the data line 3; the control processing device includes a control processing device master switch 4, a control upper joist movement button 5, a vertical arm 6, and a rotation motor control button. 7. Rotary...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap