Ferromagnetic metal nondestructive testing method based on electromagnetic loading

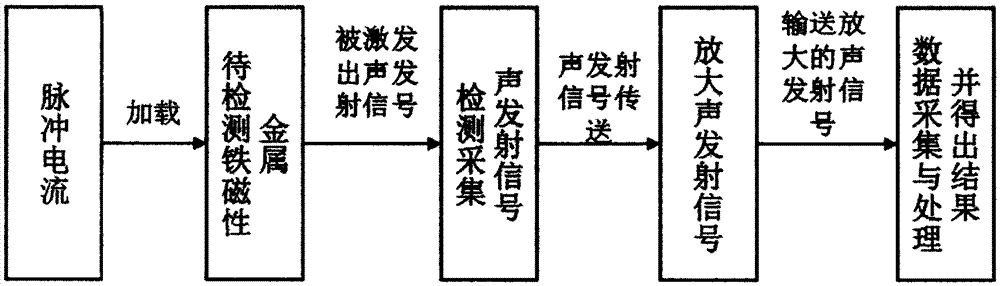

A non-destructive testing and ferromagnetic technology, applied in the fields of magnetic variables of materials, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic emission technology, which can solve problems such as difficulty in extracting materials and active state information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

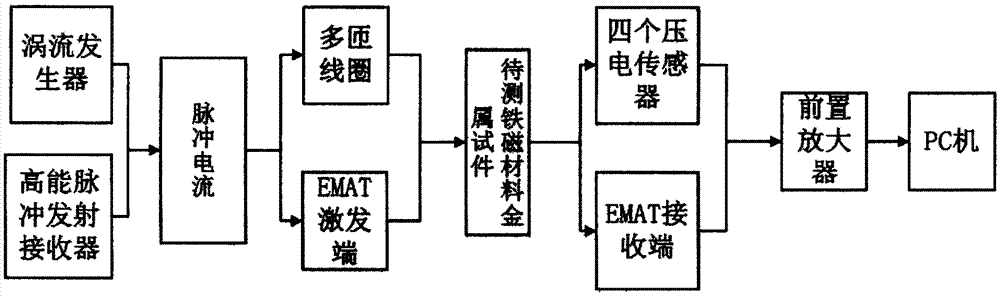

Embodiment 1

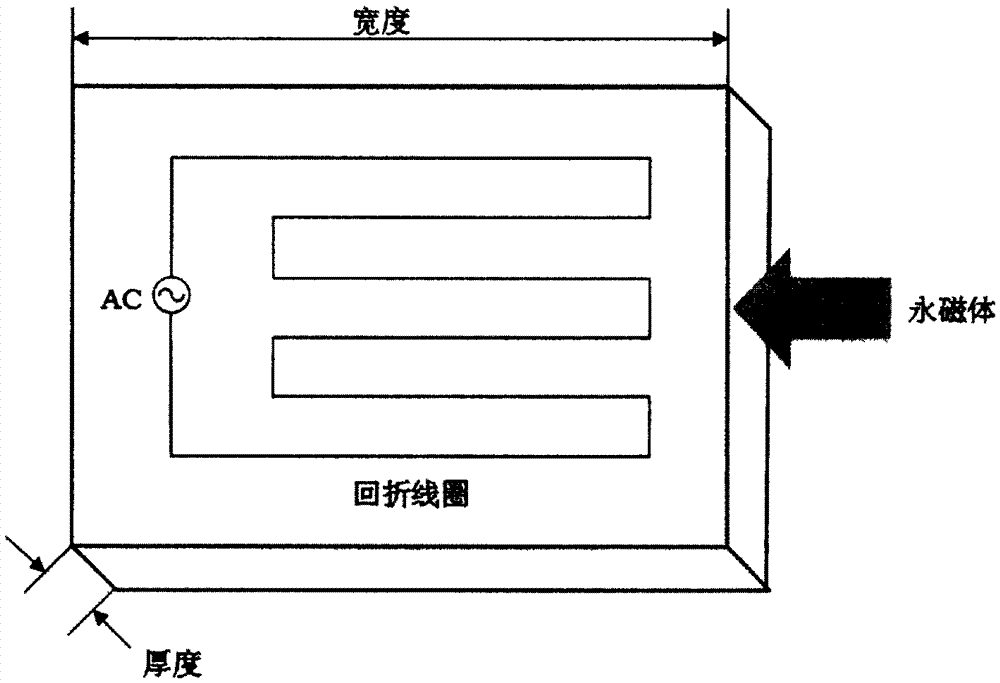

[0028] At the beginning of detection, the 220v AC is rectified to achieve 190V DC output to the 190V DC terminal in the eddy current generator, and the signal generator in the eddy current generator outputs a control signal, which is input to the 190V DC power supply in the eddy current generator The power amplifier of the power amplifier, the power amplifier inverts the voltage into an AC voltage, and after the voltage is boosted by the transformer, the pulse square wave voltage is loaded on the loop composed of the resonant capacitor and the multi-turn exciting coil, and the pulse current passing through the coil Increase from the starting point to a certain amplitude, and induce a quasi-sinusoidal eddy current on the ferromagnetic metal to be detected with a size of 500mm×115mm×15mm. If there is a defect in the ferromagnetic metal to be detected, an acoustic emission signal will be excited. The emission signal is detected by four piezoelectric sensors S 1 , S 2 , S 3 and ...

Embodiment 2

[0033] Change the multi-turn coil excitation to EMAT excitation terminal excitation, and the others are the same as in embodiment 1.

[0034] The final positioning detects the defect position of the ferromagnetic metal material to be detected, and the positioning error is 1-2 mm, and finally determines the activity of the defect.

Embodiment 3

[0036] The vortex generator is replaced by a high-energy pulse transmitting and receiving device, and the others are the same as in Embodiment 1.

[0037] The final positioning detects the defect position of the ferromagnetic metal material to be detected, and the positioning error is 1-2 mm, and finally determines the activity of the defect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com