Antibacterial damping foam for fruits and vegetables

A foam, fruit and vegetable technology, applied in the fields of fruit and vegetable preservation, application, food science, etc., can solve the problems of easy spoilage and deterioration of fruits and vegetables, and achieve the effect of good broad-spectrum antibacterial effect and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

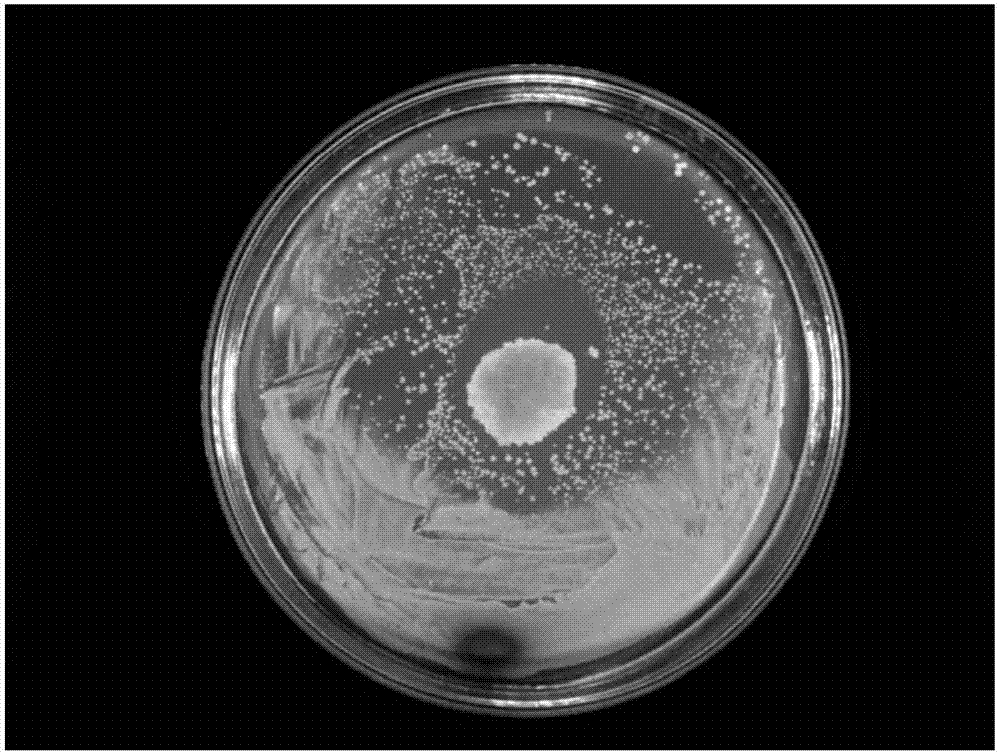

Image

Examples

Embodiment 1

[0025] Take 10g of polylactic acid and add 70g of dichloromethane, fully stir to dissolve at 40℃, add 0.2g of linalool, 0.8g of citral, 0.3g of tributyl citrate, stir well, add 120g of sodium bicarbonate, and stir for 15min. , Pour into the abrasive tool and dry naturally at 25℃. The dried solid was put into a saturated aqueous solution of citric acid and soaked at 30°C for reaction. After no bubbles were released, the foam was taken out, and vacuum dried to obtain a white polylactic acid antibacterial shock-absorbing foam for fruits and vegetables. After testing, the antibacterial shock-absorbing foam for fruits and vegetables has a porosity of 90.7% and an elasticity of 0.67.

Embodiment 2

[0027] Take 20g of polylactic acid and add it to 160g of chloroform, stir to dissolve it at 50℃, add 1g of linalool, 2g of citral, 0.8g of tributyl citrate, stir well, add 240g of sodium bicarbonate, mechanically stir for 15min, pour into the mill Dry naturally at 25℃. The dried solid is put into a saturated aqueous solution of citric acid and soaked at 60°C for reaction. After no bubbles are released, the foam is taken out and vacuum dried to obtain a white polylactic acid antibacterial shock-absorbing foam for fruits and vegetables. After testing, the antibacterial shock-absorbing foam for fruits and vegetables has a porosity of 90.1% and an elasticity of 0.52.

Embodiment 3

[0029] Take 5g of polylactic acid and add it to 45g of chloroform, stir to dissolve it at 55℃, add 0.8g of linalool, 0.2g of citral, and 0.2g of tributyl citrate, stir well, add 75g of sodium bicarbonate, stir mechanically for 15min, pour Put it into the mold and dry it naturally at 25°C. The dried solid is put into a saturated aqueous solution of citric acid and soaked at 80°C for reaction. After no bubbles are released, the foam is taken out and vacuum dried to obtain a white polylactic acid antibacterial shock-absorbing foam for fruits and vegetables. After testing, the antibacterial shock-absorbing foam for fruits and vegetables has a porosity of 92.6% and an elasticity of 0.61.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com