Processing device and method for wood processing

A technology for processing equipment and wood, which is applied in the direction of wood processing equipment, sawing equipment, manufacturing tools, etc. It can solve problems such as cracks, large stress area, damage, etc., and achieve smooth cutting, good consistency of cutting direction, and rough edges little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

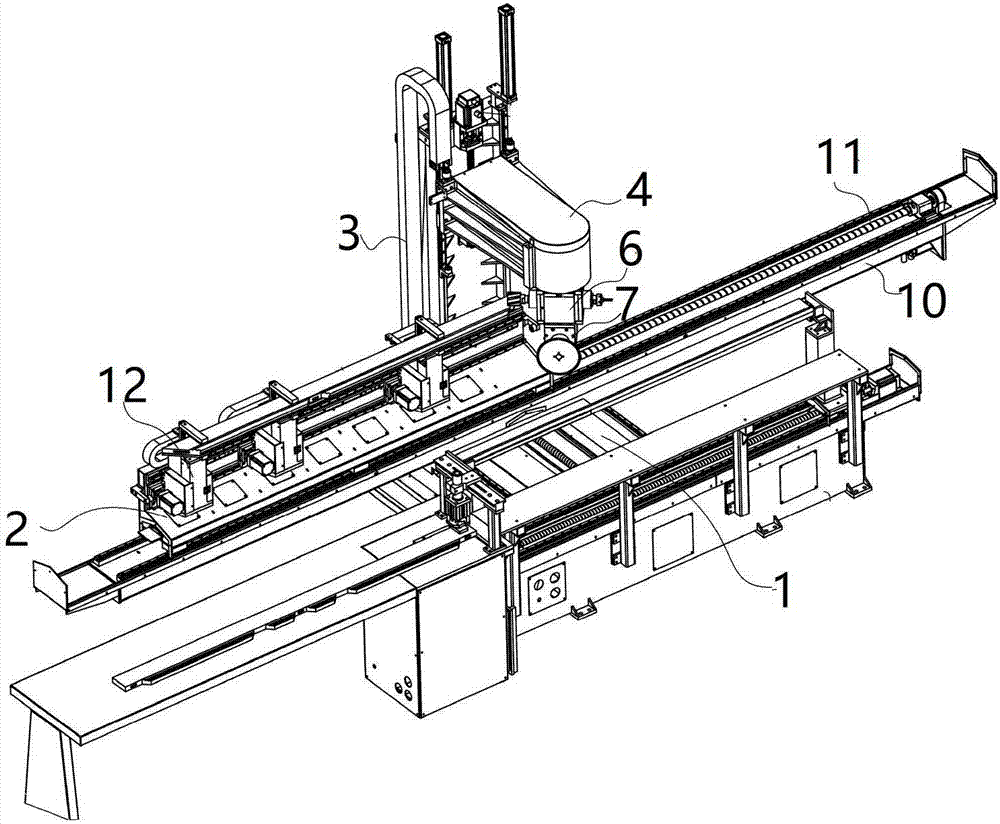

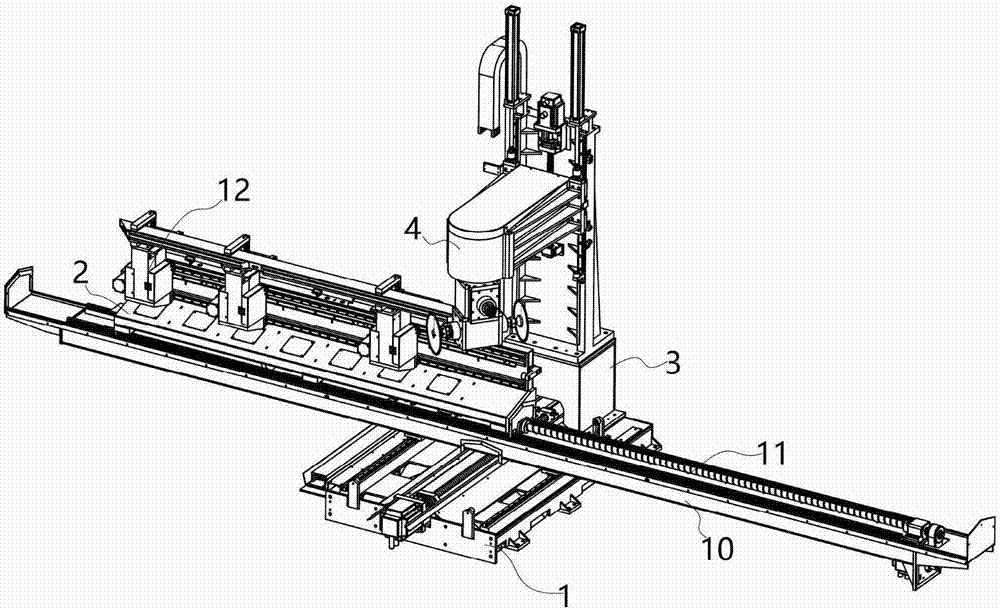

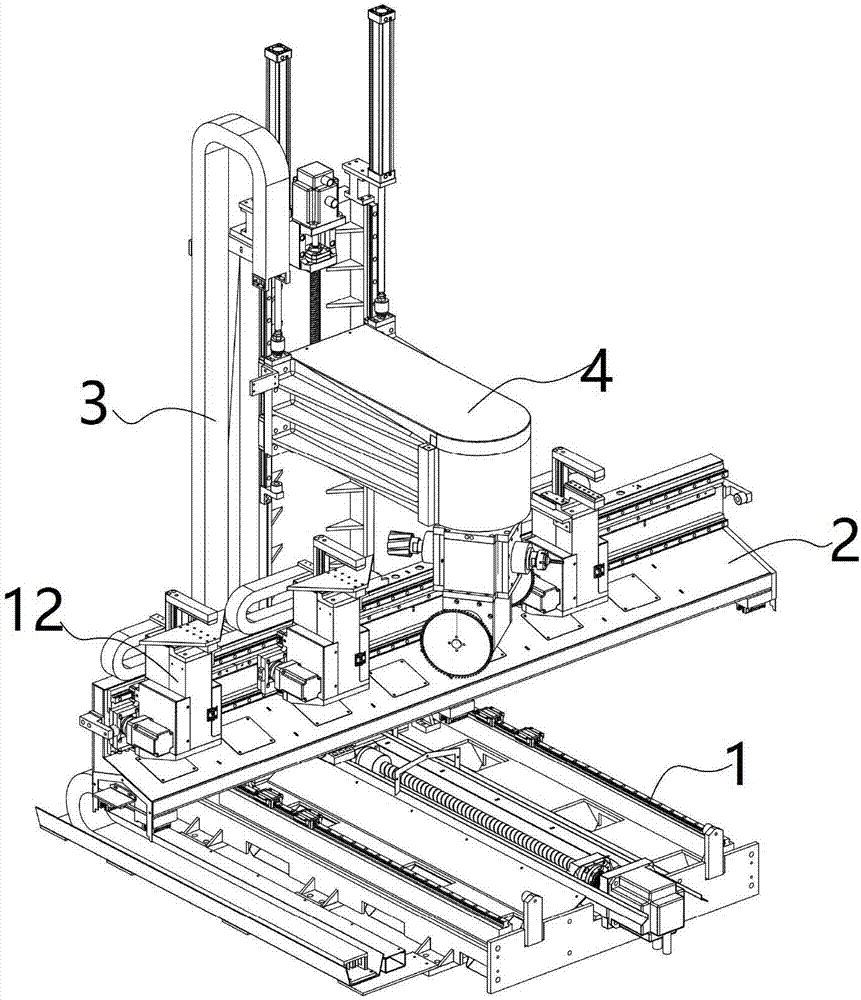

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as Figure 1-5 As shown, the specific embodiment of the present invention is a kind of processing equipment for wood processing, including a machine base 1, a workbench 2 for fixing wood 15 is arranged above the machine base 1, and on the machine base 1 A vertical movable seat 3 is provided, and a processing box 4 is movable on the vertical movable seat 3, and the processing box 4 moves vertically up and down along the vertical movable seat 3;

[0030] The inner side of the processing box 4 is provided with a rotating motor 5, and the rotating motor 5 is driven and connected with a tenon knife driving module 6 and a saw blade driving module 7, and the two ends of the saw blade driving module 7 are respectively driven and connected with a vertically arranged first For the saw blade 8 and the second saw blade 9 , the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com