Feller delimbing device

A technology of a feller and a robotic arm, applied in the field of feller components, can solve the problems of large blade wear, affecting the logging efficiency, and the trunk cannot continue to drive, so as to improve the service life and use stability, and prevent the reaction force from being damaged. Clear Efficient Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

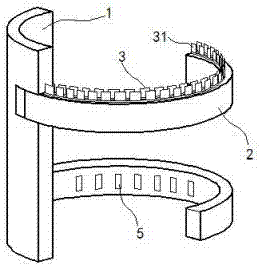

[0015] exist figure 1 , figure 2 In the shown embodiment, the delimbing device of the logging machine includes a base plate 1 and a mechanical arm 2, the mechanical arm 2 is pivotally connected to the base plate 1, and the movement of the mechanical arm 2 is controlled by a driving motor;

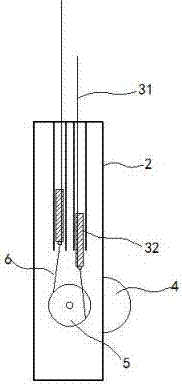

[0016] The mechanical arm 2 is arc-shaped, and a cutting knife group is arranged in the mechanical arm 2. The cutting knife group includes two groups of parallel knife rows 3, and each row of knife rows 3 includes a knife seat 32 and a blade 31. Blade 31 stretches out from the upper surface of mechanical arm 2; figure 1 Shown; Each row of knife rows 3 can reciprocate and translate in the plane where the blade 31 is located; the blade 31 is made of a permanent magnetic material, and the magnetic heteropoles of each row of blades 31 attract each other;

[0017] The inner ring arm of described mechanical arm 2 is provided with driving roller 4, and driving roller 4 can rotate freely around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com