Anti-pollution window for heat evaporation coating instrument

A coating instrument and anti-pollution technology, which is applied in the field of anti-pollution windows, can solve problems such as hindering condensation, and achieve the effect of improving cleanliness and clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

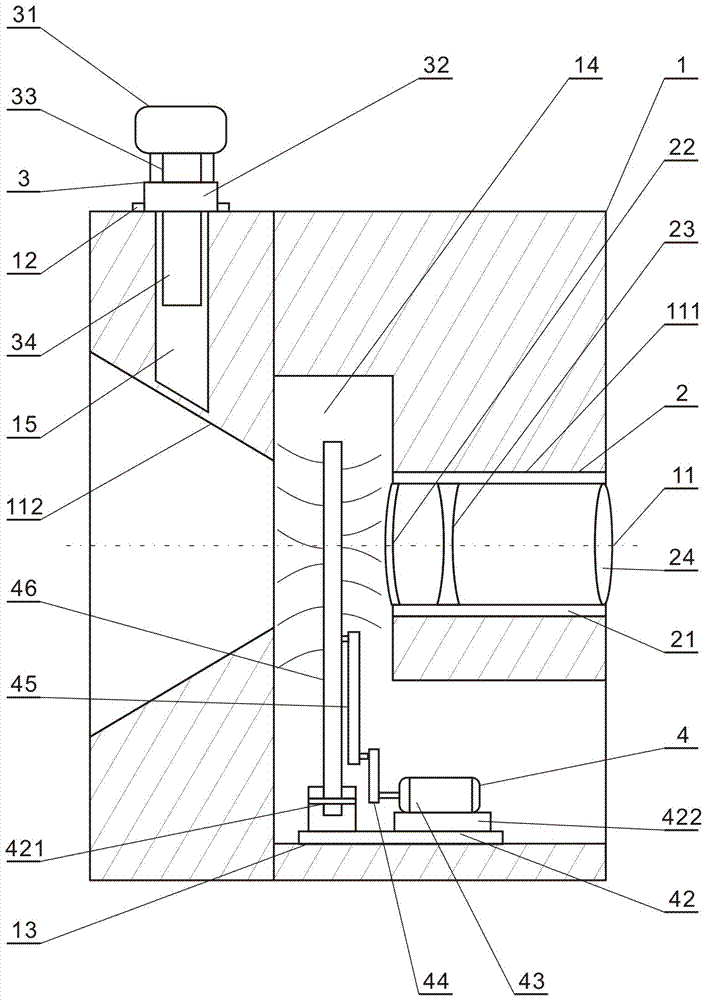

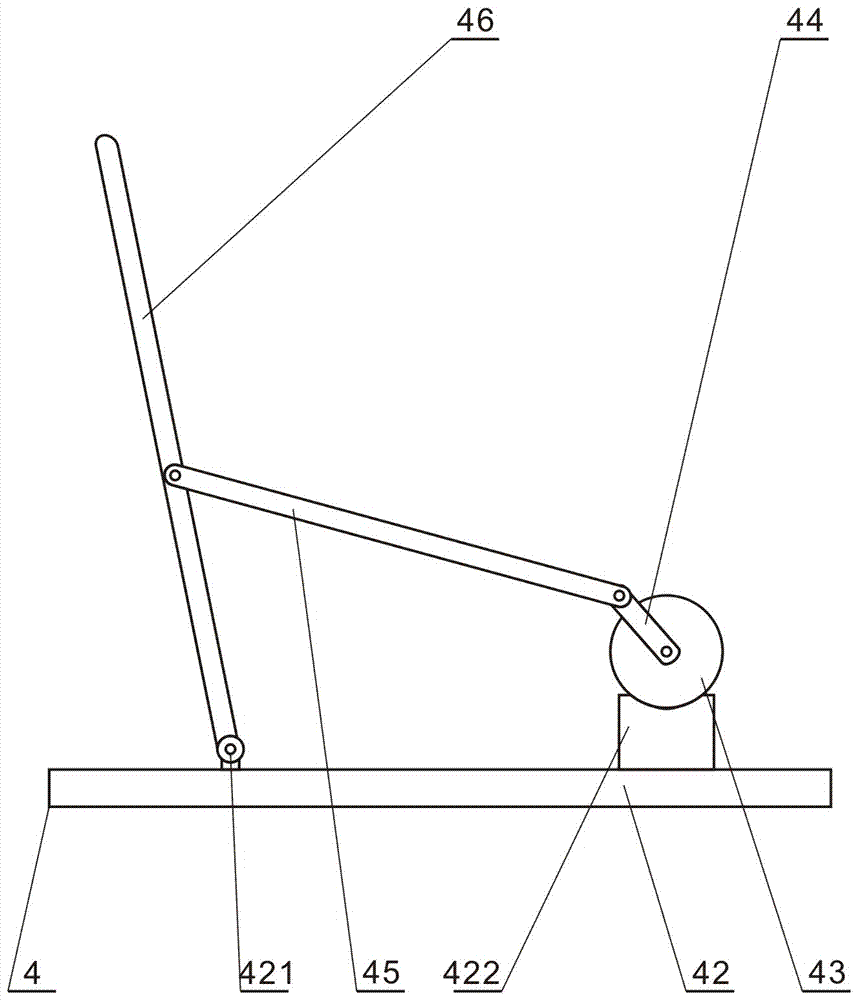

[0023] refer to figure 1 , figure 2 , the present invention provides an anti-pollution window for a thermal evaporation coating instrument, comprising a condensation chamber 1, a peephole 2, a semiconductor refrigerator 3 and a sweeping module 4. When in use, only the bell mouth 112 of the condensation chamber 1 and the The viewing port of the evaporating container can be aligned and installed. For ease of operation, the present invention provides a sweeping module 4 switch and a semiconductor refrigerator 3 switch outside the condensation chamber 1 for manipulation by experimenters. The rotation speed of the stepper motor 43 is controlled by the switch of the sweeping module 4 to control the stop, start and swing speed of the rocker 46;

[0024] refer to figure 1 , figure 2 , the present invention sets observation hole 11, refrigerator seat 12, sweeping module seat 13, sweeping rod cavity 14 and vertical air duct 15 in condensation chamber 1, and observation hole 11 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com