Application of cationic etherification polyvinyl alcohol in gummy substance control

A technology of cationic etherification and stickies control, applied in paper, textile and papermaking, non-fibrous pulp addition, etc., can solve the problems of reducing the production efficiency of paper machines, and achieve the effect of reducing sticky deposits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

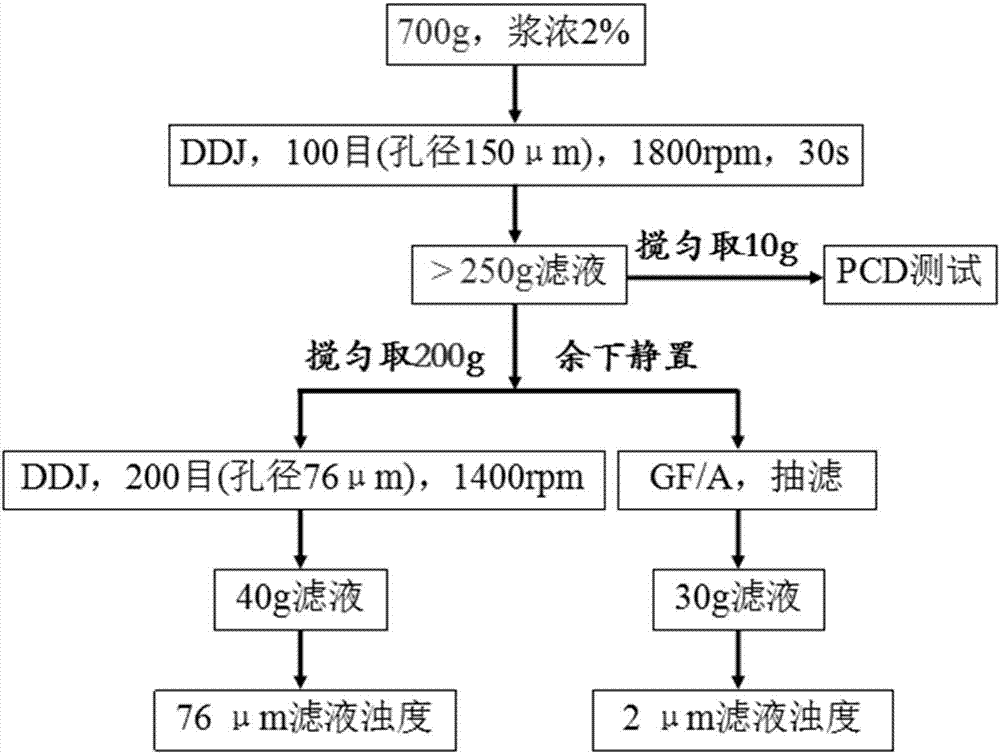

Method used

Image

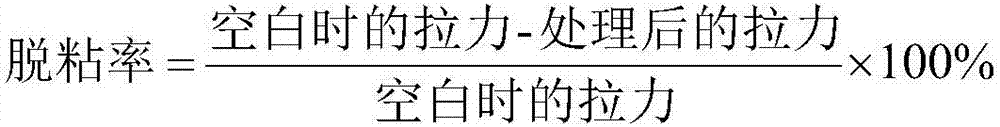

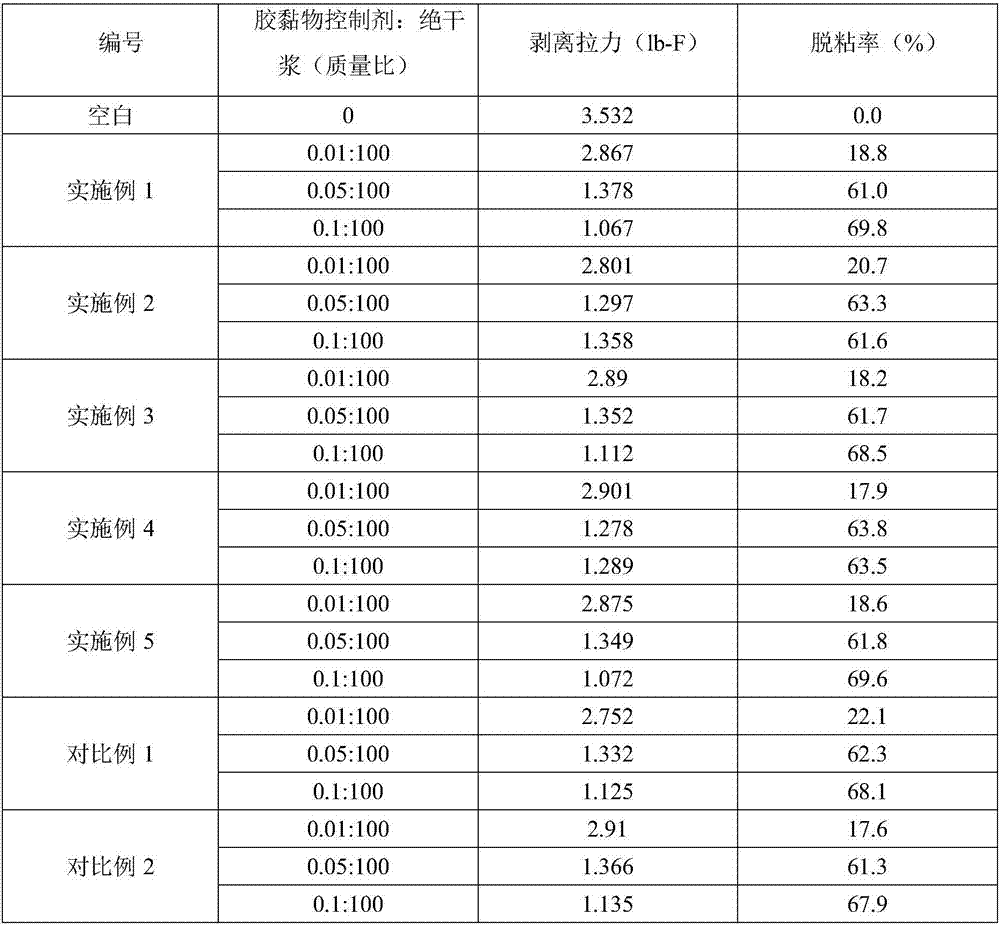

Examples

Embodiment 1

[0047] Add 242.1g of distilled water (temperature lower than 30°C) into the four-necked bottle, start stirring, and slowly add 35.5g of polyvinyl alcohol 08835 at a slow and uniform rate to prevent the formation of lumps. Stir for 15 minutes, then raise the temperature to 90±5°C, and keep at 90±5°C for 60 minutes. Then cool down to 65°C, add 44.36g of 3-chloro-2-hydroxypropyltrimethylammonium chloride, add 65.72g of potassium hydroxide aqueous solution with a mass fraction of 20%, react at 65°C for 240min, then add hydrochloric acid to adjust the pH to 6-7. Finally, 108 g of distilled water was added and stirred evenly to obtain cationic etherified polyvinyl alcohol 1.

Embodiment 2

[0049] Add 228.42g of distilled water (temperature lower than 30°C) into the four-necked bottle, start stirring, and slowly add 33.5g of polyvinyl alcohol 08850 at a slow and uniform rate to prevent the formation of lumps. Stir for 15 minutes, then raise the temperature to 90±5°C, and keep at 90±5°C for 60min. Then cool down to 65°C, add 41.85g of 2,3-epoxypropyltrimethylammonium chloride, add 90g of sodium hydroxide aqueous solution with a mass fraction of 20%, react at 65°C for 240min, then add hydrochloric acid to adjust the pH to 6- 7. Finally, 102 g of distilled water was added and stirred evenly to obtain cationic etherified polyvinyl alcohol 2.

Embodiment 3

[0051] Add 228.42g of distilled water (temperature lower than 30°C) into the four-necked bottle, start stirring, and slowly add 33.5g of polyvinyl alcohol 08850 at a slow and uniform rate to prevent the formation of lumps. Stir for 15 minutes, then raise the temperature to 90±5°C, and keep at 90±5°C for 60min. Then cool down to 65°C, add 41.85g of 3-chloro-2-hydroxypropyltrimethylammonium chloride, add 72g of aqueous sodium hydroxide solution with a mass fraction of 20%, react at 65°C for 240min, and then add hydrochloric acid to adjust the pH to 6 -7. Finally, 102 g of distilled water was added and stirred evenly to obtain cationic etherified polyvinyl alcohol 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com