Sound elimination enclosure plates and enclosure system

A technology of enclosure boards and slabs, applied in the direction of covering/lining, construction, building construction, etc., to achieve the effect of reducing noise hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

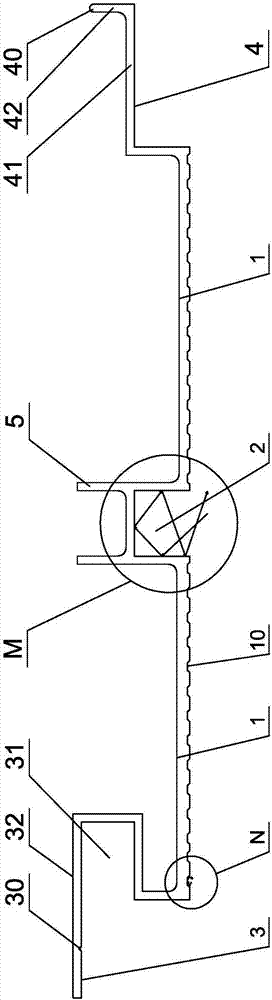

[0058] Such as figure 1 , Figure 6 ~ Figure 8 As shown, the anechoic enclosure panel of this embodiment includes a panel face, and connecting and fixing parts 3 and overlapping fastening parts 4 located on both sides of the board face in the width direction. They are fixedly connected with each other, and the two adjacent noise-absorbing enclosures are lapped and fastened on the connection and fixing part 3 through the lap fastening part 4 to realize screwless buckle connection, so that the board surface is simple , beautiful, the surface of the board includes convex strips 1 and grooves 2 arranged longitudinally and alternately, when external sound passes through the sound-absorbing enclosure, reflection and refraction occur at the groove 2 to generate energy Converting, converting sound waves into mechanical energy and heat energy, so that the sound can reverberate here to play the role of noise reduction; the exposed surface of the convex strip 1 is provided with several ...

Embodiment 2

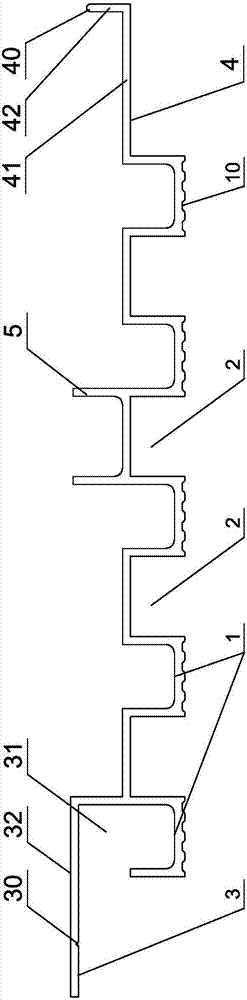

[0060] Such as figure 2 , Figure 9 As shown, the difference between the noise-absorbing enclosure of this embodiment and Embodiment 1 is that: in this embodiment, the cross-section of the raised strip 1 is square; the cross-section of the groove 2 is rectangular; the There are five ridges 1 with a smaller width, and four grooves 2.

[0061] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

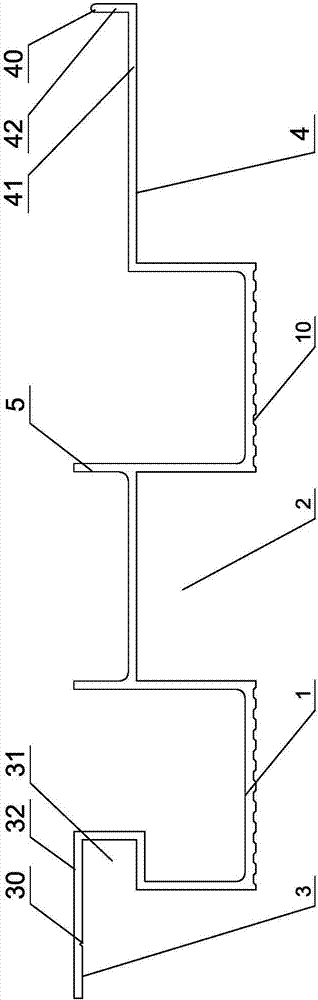

[0063] Such as image 3 , Figure 10 As shown, the difference between the noise-absorbing enclosure of this embodiment and Embodiment 1 is that: in this embodiment, the cross-sections of the raised strips 1 and the grooves 2 are rectangular, and the sizes are uniform and uniform. distributed.

[0064] The remaining features of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com