Balance shaft

A technology of balancing shaft and balancing part, applied in the field of balancing shaft, can solve problems such as the weight of large components, and achieve the effect of improving mass distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

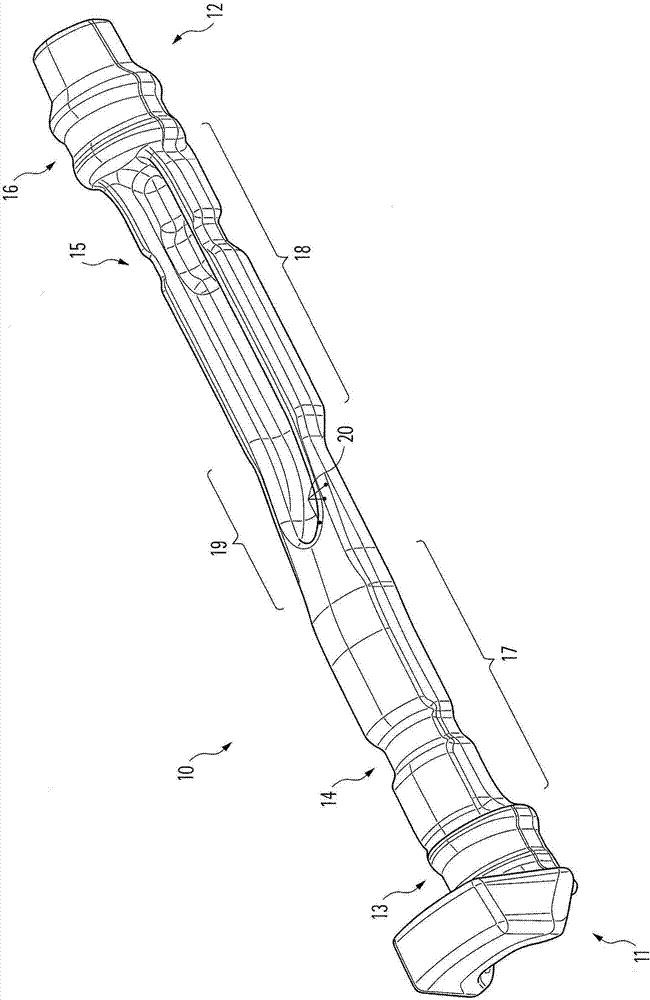

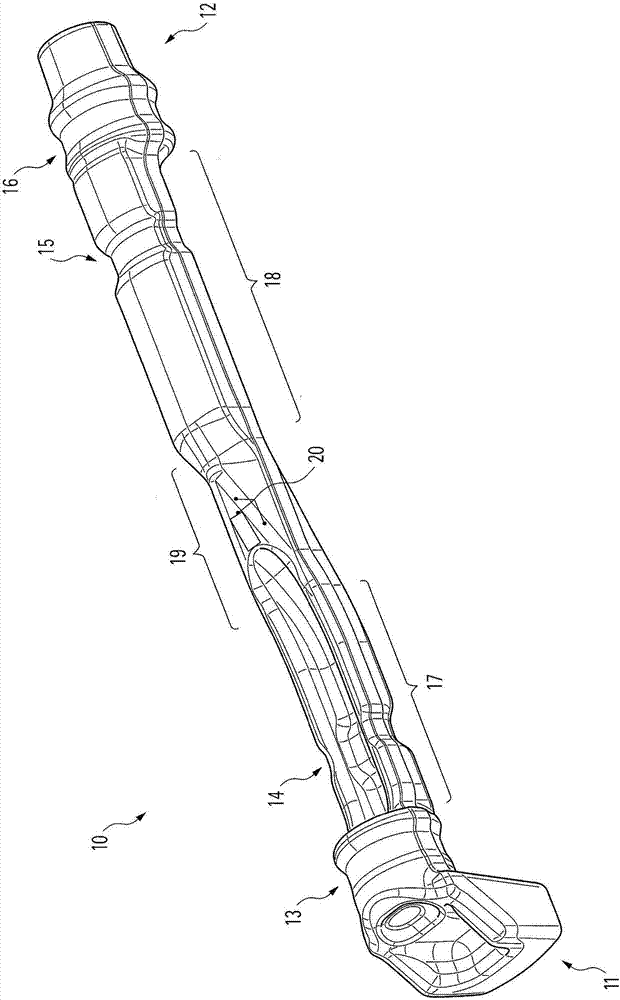

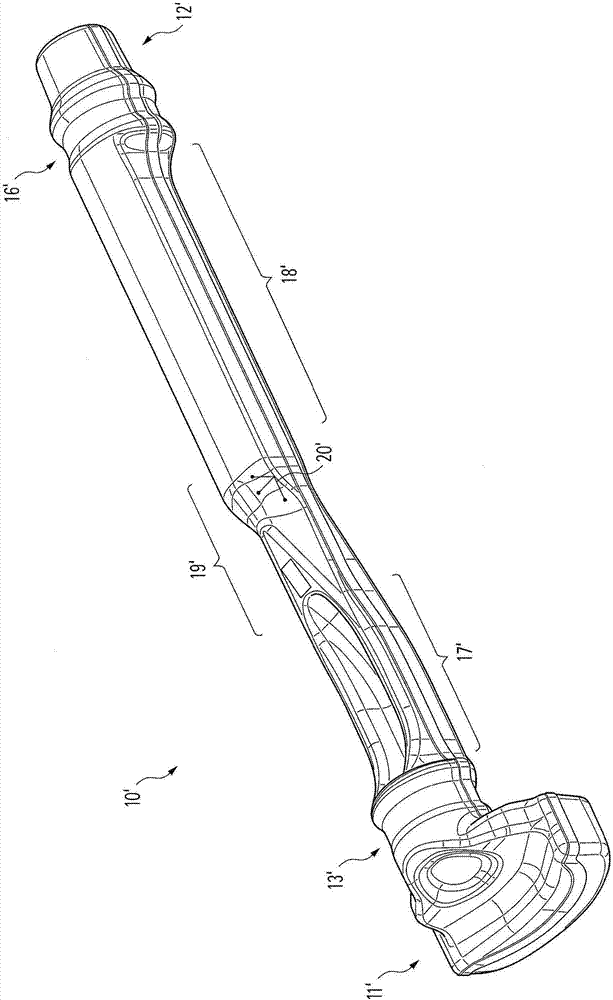

[0029] figure 1 and figure 2 A first embodiment of the balance shaft 10 of the present invention is shown. The balancing shaft 10 comprises two coupling parts 11 , 12 at opposite ends, whereby the balancing shaft 10 can be connected to a drive, in particular a sprocket drive.

[0030] In this embodiment the balancing shaft 10 also comprises four journals 13 , 14 , 15 , 16 for the mounting of radial bearings. The axis of rotation of the balancing shaft 10 is located at the center point of the journals 13 , 14 , 15 , 16 .

[0031] The journals 13 , 16 can each have a bearing inner ring on or at which a bearing (preferably a roller bearing) can be mounted in each case. In this connection it is preferred that the journals 13 , 16 are provided by bearing inner rings integrally formed on the main body, on which the bearings can then be slipped or clamped. For example, a bearing inner ring can be provided in which two correspondingly formed shoulders (not shown) which in combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com