Loading and unloading equipment of engine part hot cracking furnace

A technology of parts and pyrolysis, applied in the direction of lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of inconvenient use, unreasonable structure design, complicated operation, etc., and achieve convenient use, reasonable overall structure design, and simple operation safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

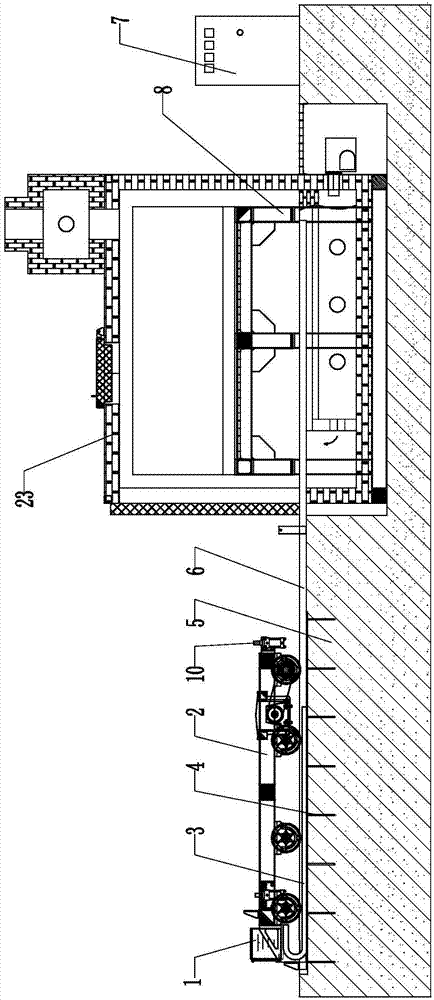

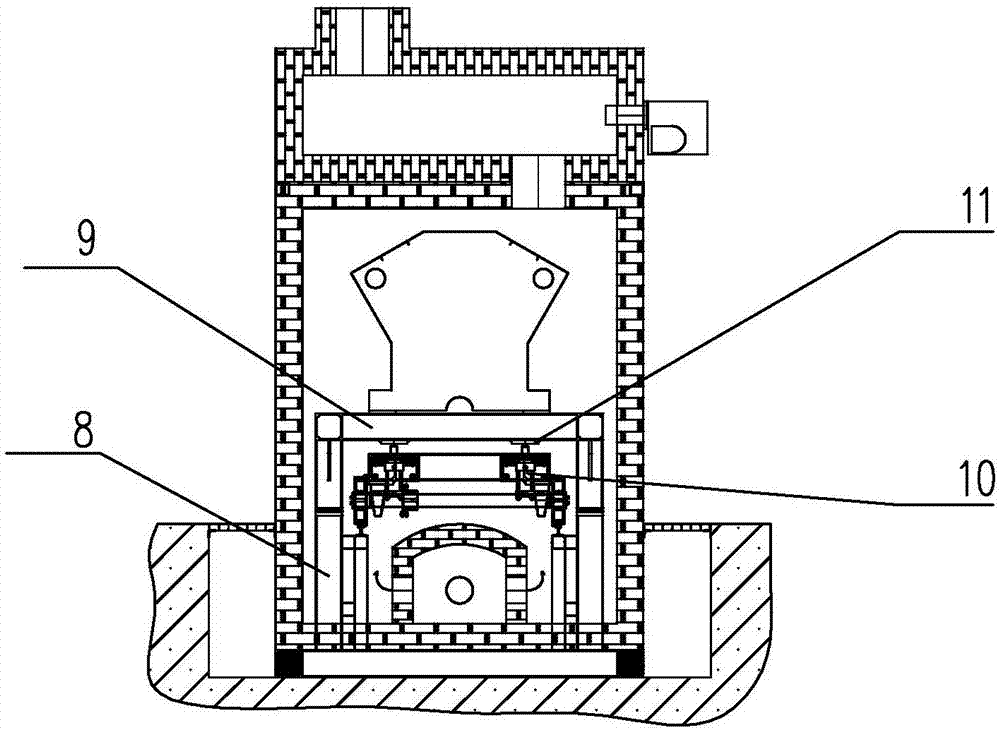

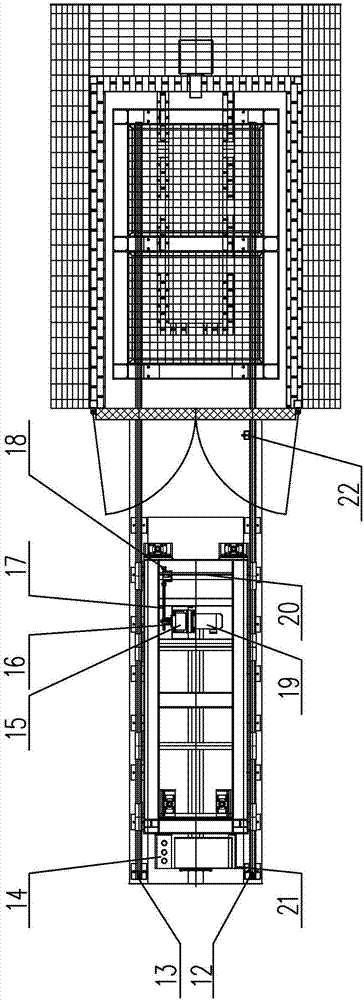

[0017] As attached Figure 1-Figure 3 In the illustrated embodiment, the present invention is provided with: a reinforced concrete base 5, a thermal cracking furnace body 23, an electric control system, a load-bearing column 8 in the furnace, a ground fixing assembly, and a moving mechanism for engine parts. The moving mechanism for engine parts is an electric conveyor The vehicle mechanism and the ground fixing component are composed of a steel rail 6 connected and fixed to a reinforced concrete base 5 through a number of anchor bolts 4, the steel rail 6 is a parallel double rail, and the top head of the steel rail 6 is connected to the thermal cracking furnace body 23 In the furnace cavity of the steel rail 6, an electric control system, an electric transport vehicle mechanism, and a transport vehicle retreat proximity switch 21 and a transport vehicle forward proximity switch 22 are respectively installed on the steel rail 6. The load-bearing column 8 is connected to the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com