Device for measuring deformation of relieved end roller of bearing under load

A technology for measuring device and deformation, which is applied in the direction of measuring device, mechanical bearing test, optical device, etc., can solve the problems of lack of design and test basis for roller modification amount, restrict the independent research and development of roller bearings, etc., and improve the test accuracy , Enhance the effect of reflective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

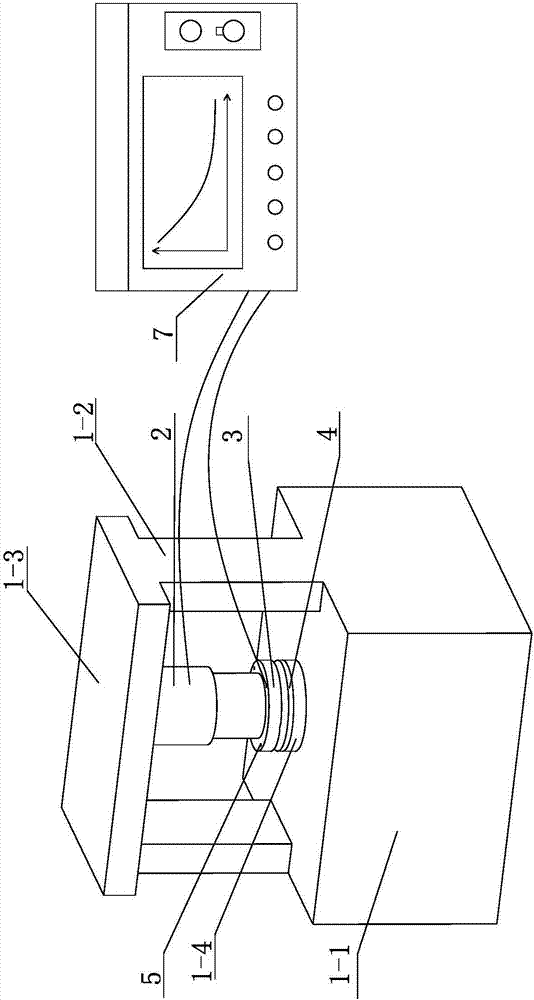

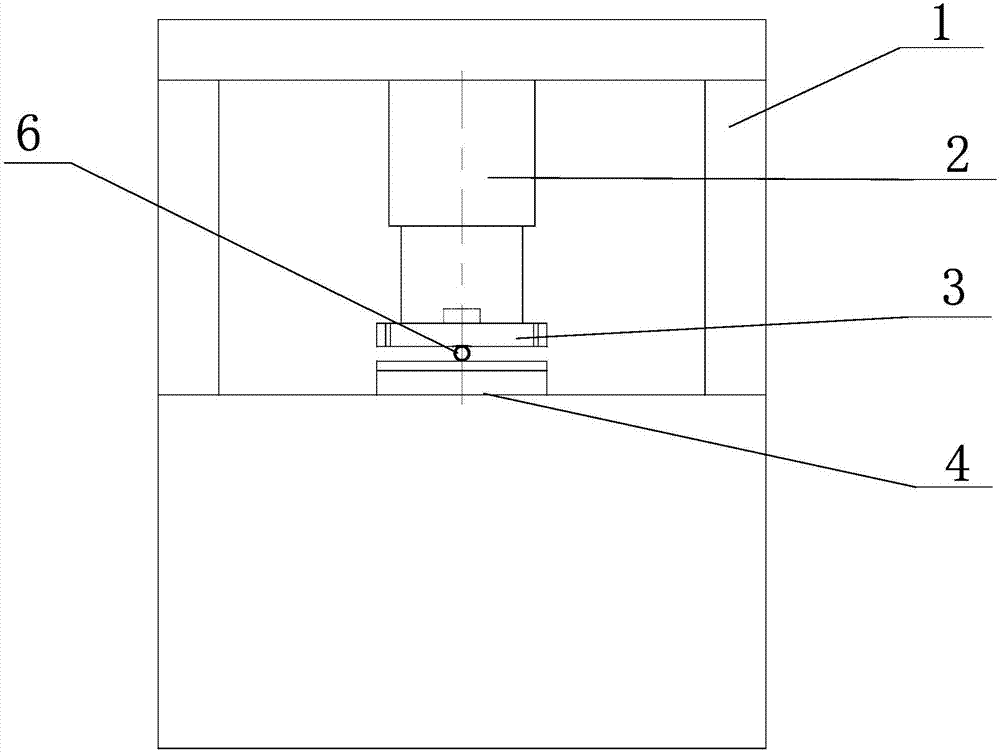

[0010] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the device for measuring the amount of deformation of a bearing modifying roller under load described in this embodiment, which includes a test bench body 1, a hydraulic loading system 2, a pressure plate 3, a support plate 4, a controller 7, data recorder 8 and a plurality of optical fiber sensors 5, the test bench body 1 includes a base 1-1, a crossbeam 1-3, a support platform 1-4 and two support columns 1-2, and the two support columns 1-2 are vertical Installed on the upper end surface of the base 1-1, the crossbeam 1-3 is arranged on two support columns 1-2, and one end of the crossbeam 1-3 is installed on the top of a support column 1-2, the crossbeam 1-3 The other end is installed on the top of another support column 1-2, the support platform 1-4 is installed on the base 1-1 between the two support columns 1-2, and the support plate 4 is installed on the support platform 1-4 O...

specific Embodiment approach 2

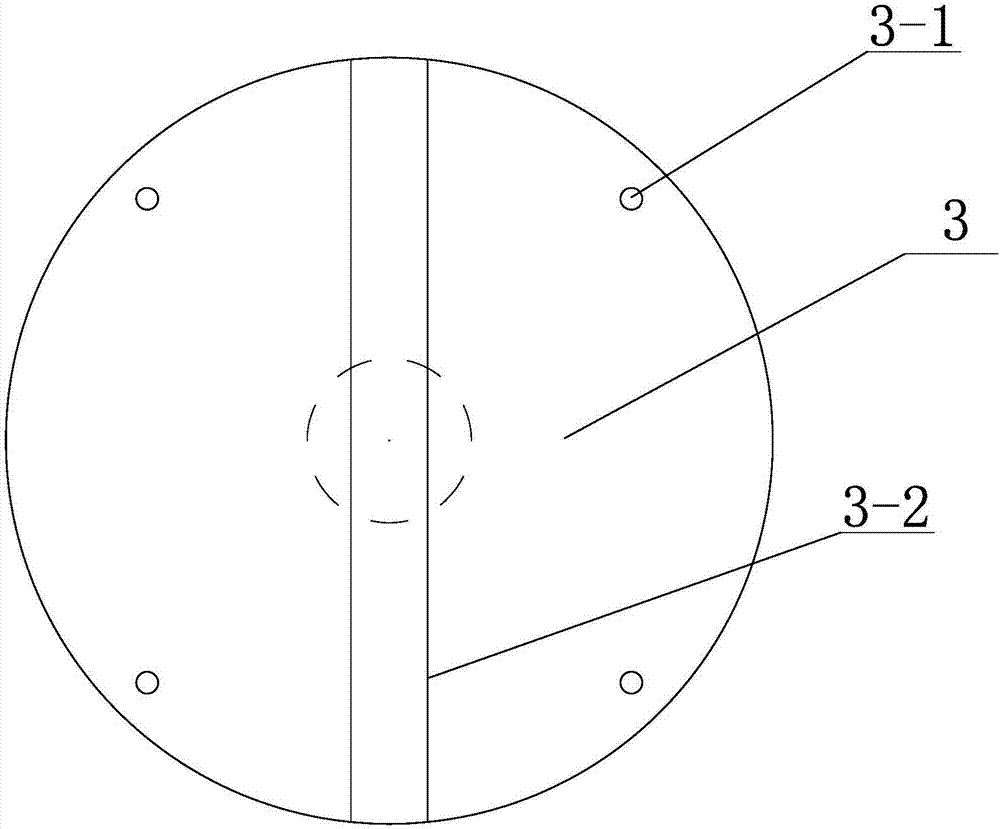

[0013] Specific implementation mode two: combination Figure 1-Figure 3 This embodiment is described. A device for measuring the deformation of a bearing modifying roller under load is described in this embodiment. The pressing plate 3 is processed with a plurality of round holes 3-1 along the circumferential direction, and each round hole 3-1 is equipped with a An optical fiber sensor 5, and others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, a kind of bearing modification roller deformation measurement device under load described in this embodiment, the number of circular holes 3-1 on the pressure plate 3 is four, the number of optical fiber sensors 5 is four . Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com