Pressure sensor based on thermal resistance principle and working method thereof

A pressure sensor and working method technology, applied in the direction of measuring fluid pressure, measuring fluid pressure, instruments, etc. through electromagnetic elements, can solve the problem of inability to measure pressure quickly and accurately, and achieve a simple test method, simple structure, and ensure high-precision measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

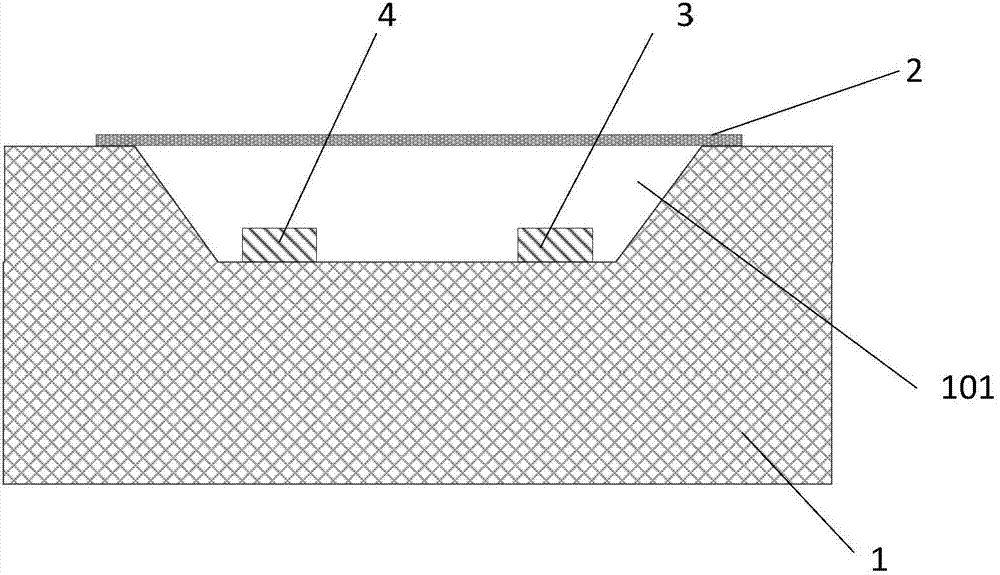

[0014] Such as figure 1 As shown, a pressure sensor utilizing the principle of thermal resistance according to an embodiment of the present invention includes a substrate 1 , a thin film 2 , a first thermal resistor 3 and a second thermal resistor 4 . The upper part of the substrate 1 is provided with a cavity 101 , the thin film 2 is grown on the top surface of the substrate 1 , and the thin film 2 covers the cavity 101 . The first thermal resistor 3 and the second thermal resistor 4 are respectively located in the cavity 101 .

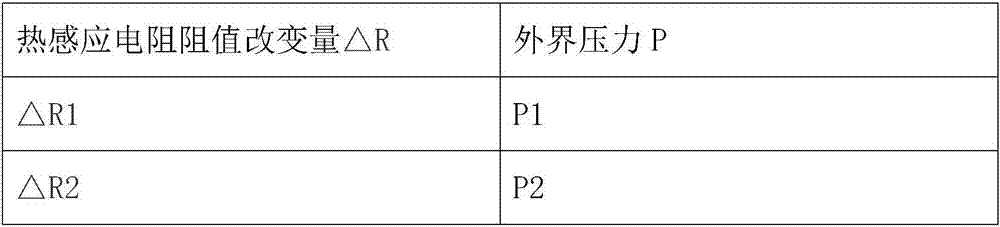

[0015] When the pressure sensor of the above-mentioned embodiment is in operation, when the external pressure is applied to the surface of the sensor, the film 2 bends, so that the distance from the film 2 to the bottom of the cavity 101 changes, and the air inside the cavity 101 is compressed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com