Loading device and loading method of geotechnical engineering model test

A technology of model testing and geotechnical engineering, applied in the field of indoor model testing of geotechnical engineering, can solve problems such as difficulties, high loading costs, and simulation of mechanical properties of rock and soil deformation, and achieve convenient operation, low experimental cost, and easy promotion and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

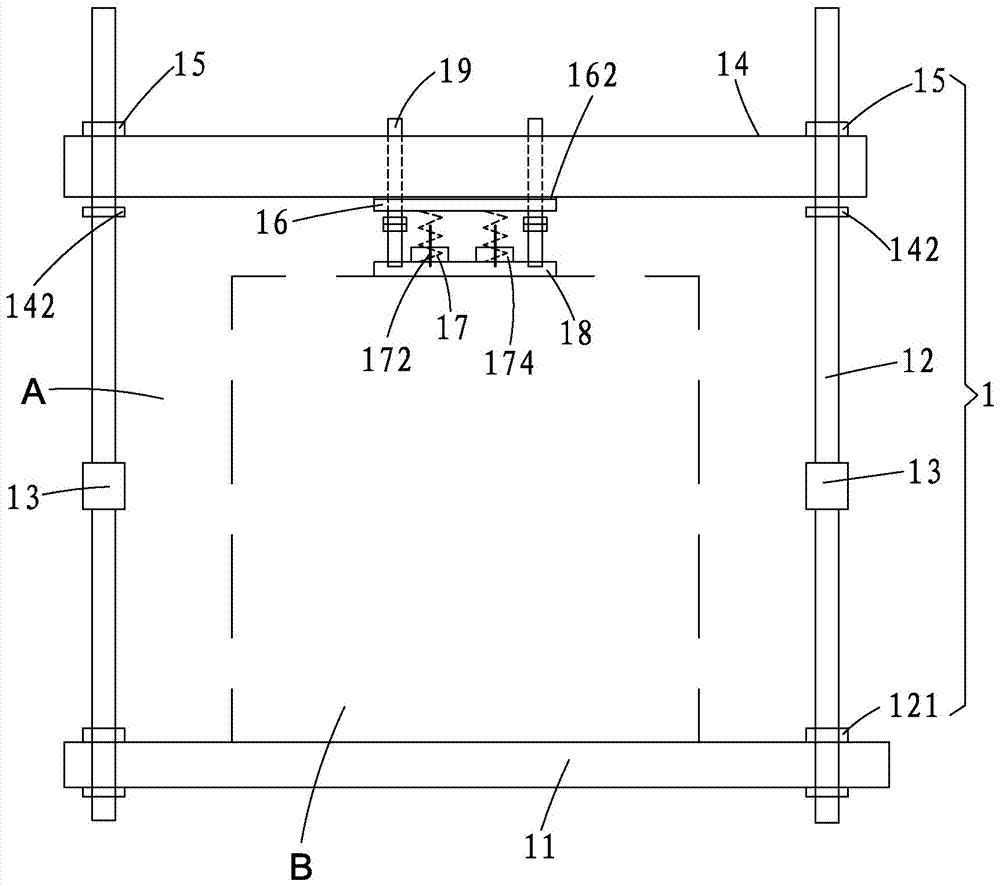

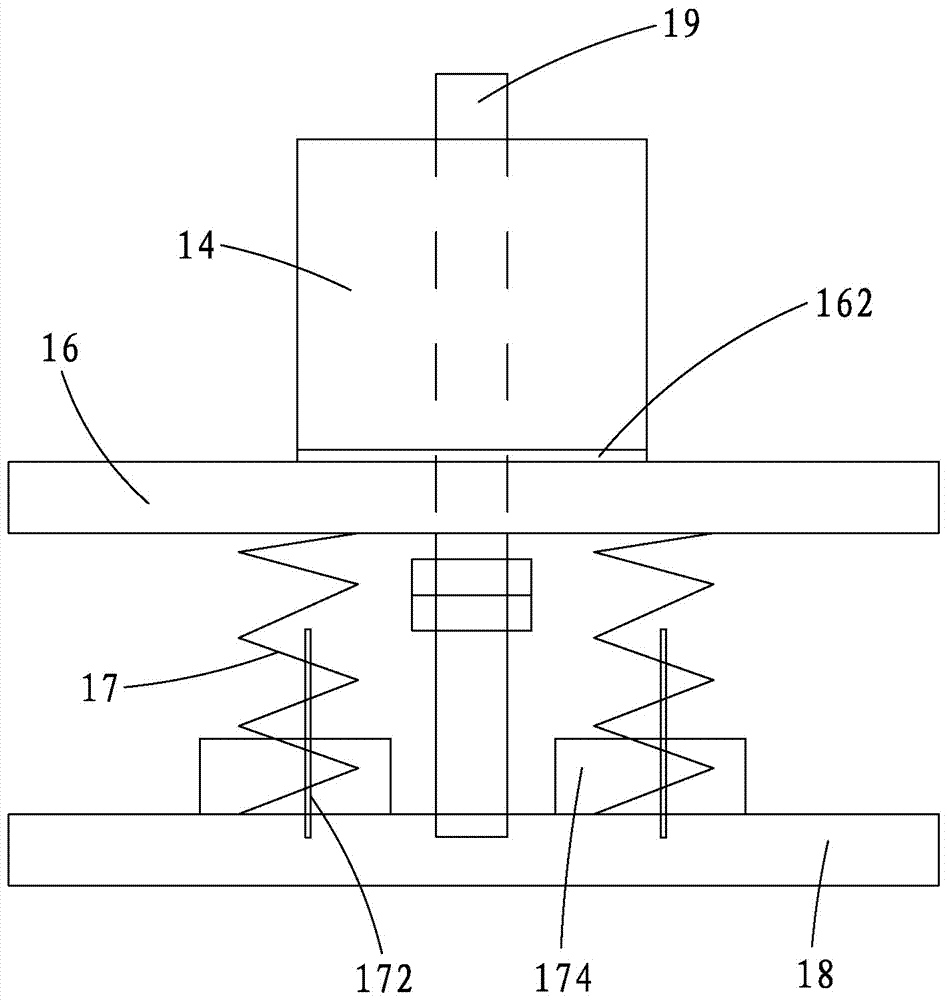

[0046] Such as figure 1 , image 3 As shown, an embodiment of the loading device of the present invention only includes a static loading mechanism 1, and the static loading mechanism 1 includes a ground anchor 11, two reaction force frame columns 12, two force sensors 13, and a reaction force frame crossbeam 14. Two loading bolts 15, a reaction force plate 16, at least two loading springs 17 and a pressure bearing plate 18; the ground anchor 11 is fixed on the ground; the two reaction force frame columns 12 are fixed by column anchor bolts 121 On the ground anchor 11; the two force sensors 13 are respectively connected to the middle section of a reaction force frame column 12; Locked from top to bottom; the reaction force plate 16 is arranged below the reaction force frame beam 14 and is fixedly connected to the pressure bearing plate 18 by the loading spring 17; the ground anchor 11, two reaction force frame columns 12. An accommodating space A for the test model B is enclo...

Embodiment 2

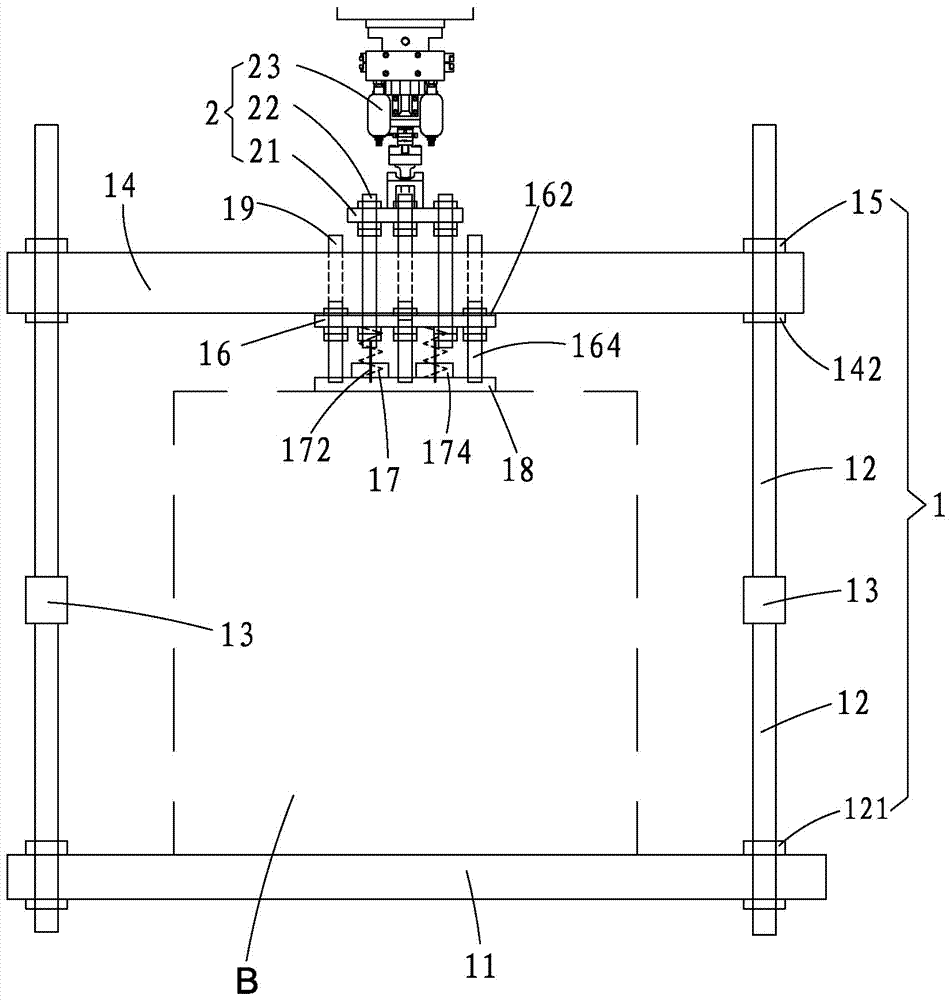

[0060] Such as figure 2 , Figure 4 as well as Figure 5 As shown, one embodiment of the loading device of the present invention includes a static loading mechanism 1 and a dynamic loading mechanism 2, that is, a dynamic loading mechanism 2 is added on the basis of the above-mentioned embodiment 1, and the dynamic loading mechanism 2 includes a terminal plate 21, end plate fixing bolt rod 22 and actuator 23, the end plate 21 and the reaction force plate 16 are connected by the end plate fixing bolt rod 22, and the actuator 23 is connected to the end plate Above the head plate 21; and the reaction force plate 16 is connected with the pressure bearing plate 18 by a reaction force plate fixing bolt rod 164, and the end plate 21, the reaction force plate 16, and the pressure bearing plate 18 are fixed by the end plate fixing bolts After the rods 22 are connected, a space dynamic load transmission system is formed. When the pressure bearing plate 18, the counter force plate 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com