Test method for desorbing volume of loss gas in shale gas well and device thereof

A technology for shale gas wells and testing methods, which is applied to the analysis of materials and instruments, can solve the problems of gas loss in shale gas content testing, and achieve the effects of direct testing methods, reduced testing costs, and avoided testing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

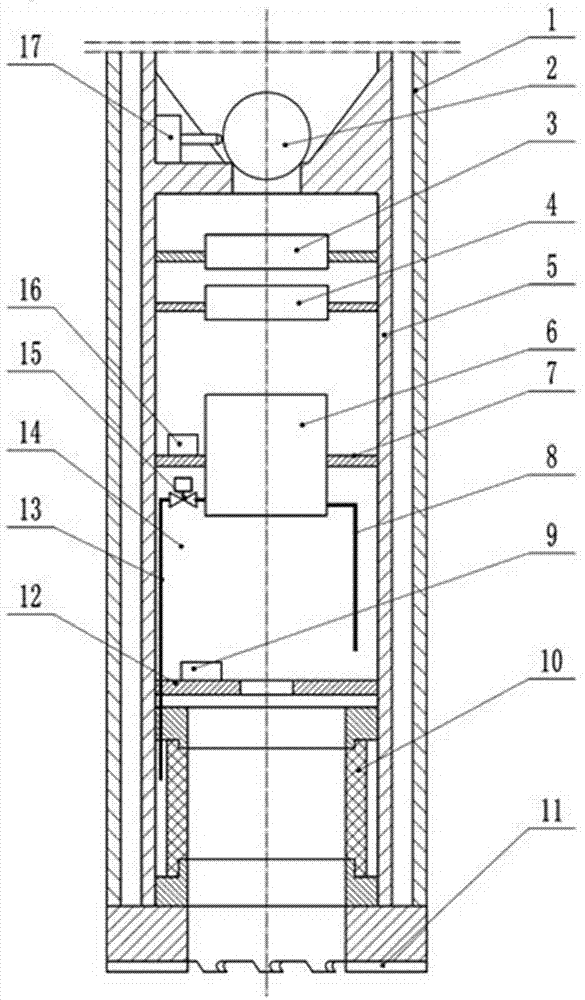

[0015] Below, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features and efficacy of a method for testing the amount of lost gas desorption in shale gas wells proposed by the present invention and its device, as well as its efficacy, are described in detail below.

[0016] see figure 1 , a method for testing the amount of desorbed gas (gas loss) in shale gas wells. When drilling and taking cores, after the coring bit 11 cuts shale, the core and mud gradually enter the coring barrel. After the core loading is completed, all the core enters When taking out the core barrel, the micro switch 17 sensor in the barrel is triggered by taking the core and throwing the ball 2. Under the instruction of the control unit 4, the high-pressure micro-constant flow pump 6 is built in the coring barrel to continuously suck the liquid in the test chamber 14, and pass The liquid discharge line 13 is pumped into the rubber cylinder 10 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com