A test system for LED photoelectric and thermal characteristics and its application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

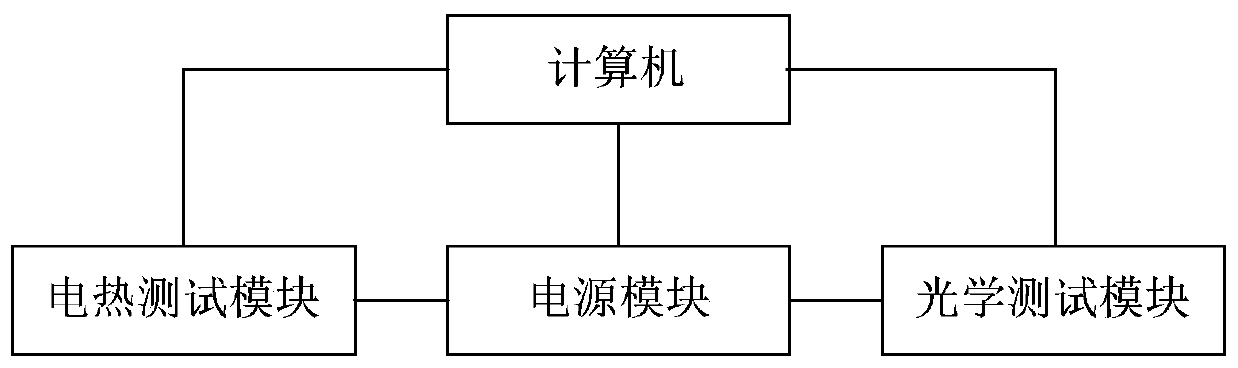

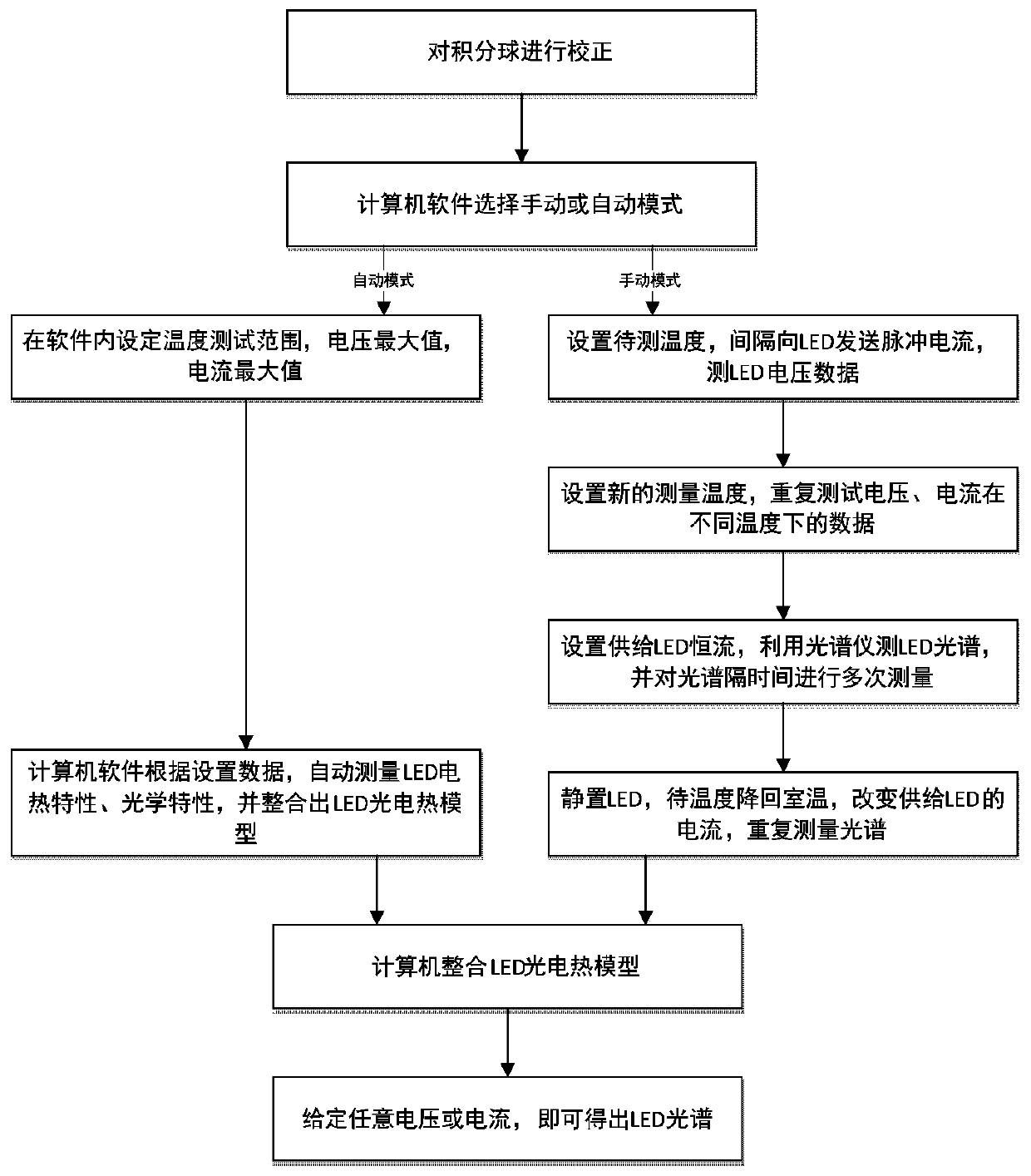

[0046] Such as figure 1 shown.

[0047] A test system for LED photoelectric and thermal characteristics, including a computer, a power supply module, an electrothermal test module and an optical test module; the computer is respectively connected to the power supply module, the electrothermal test module and the optical test module; Connect to the optical test module.

Embodiment 2

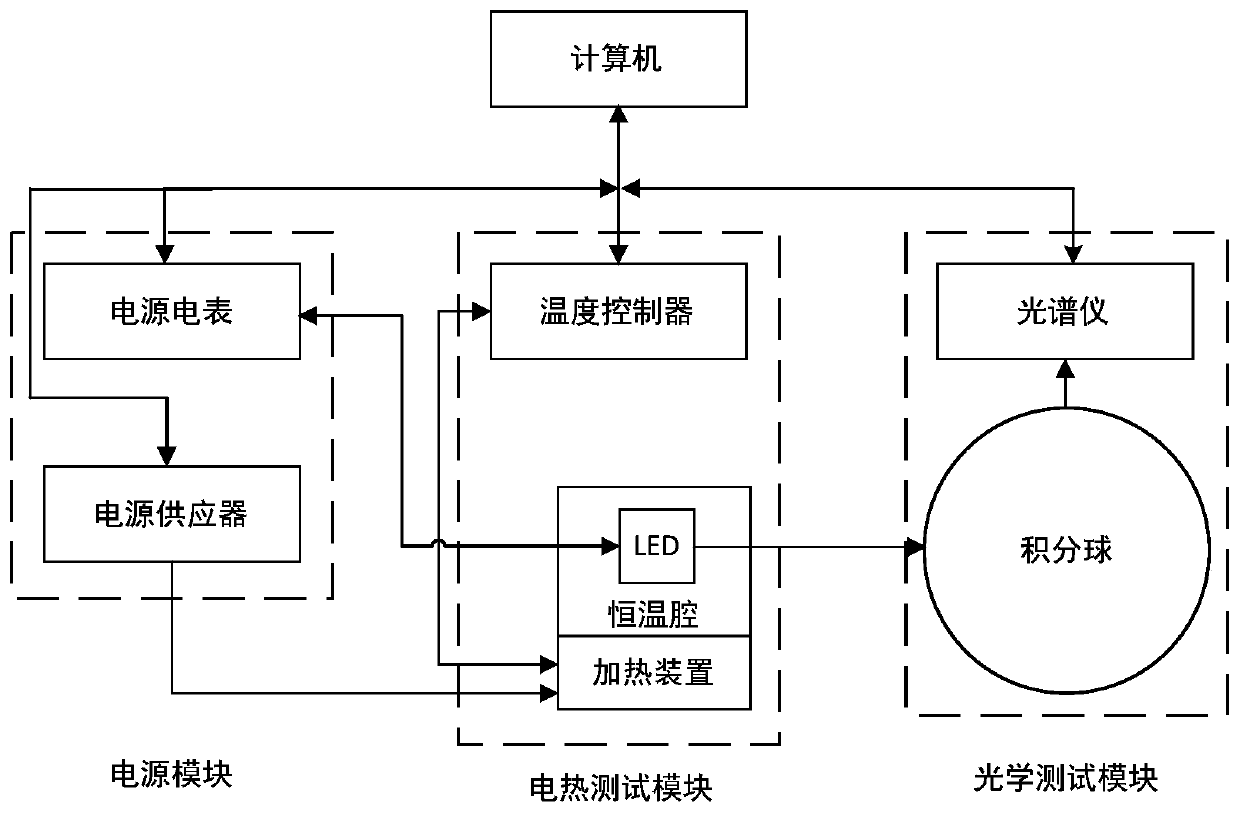

[0049] Such as figure 2 shown.

[0050] The test system for LED photoelectric thermal characteristics as described in Example 1, the difference is that the power module includes a power meter and a power supply; the electrothermal test module includes a constant temperature chamber, a heating device and a temperature controller, and the constant temperature chamber An LED is arranged inside; the optical test module includes an integrating sphere and a spectrometer; the power meter is connected to the computer and the LED respectively, and the computer is connected to the heating device through a power supply; the temperature controller is connected to the heating device and the computer respectively; The integrating sphere is respectively connected with the spectrometer and the LED, and the spectrometer is connected with the computer. When measuring the relationship between I / V and temperature, the power supply ammeter supplies LED pulse current, and when measuring the spect...

Embodiment 3

[0053] The test system for the photoelectric and thermal characteristics of LEDs described in Example 2 is different in that an LED lamp holder is provided on the integrating sphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com