Middle-convex and varying ellipse curve machining method

A processing method and ellipse-changing technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve problems such as complicated programming, long programming time, troublesome adjustment, etc., and achieve convenient program adjustment, simplified programming, and The effect of proofreading convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

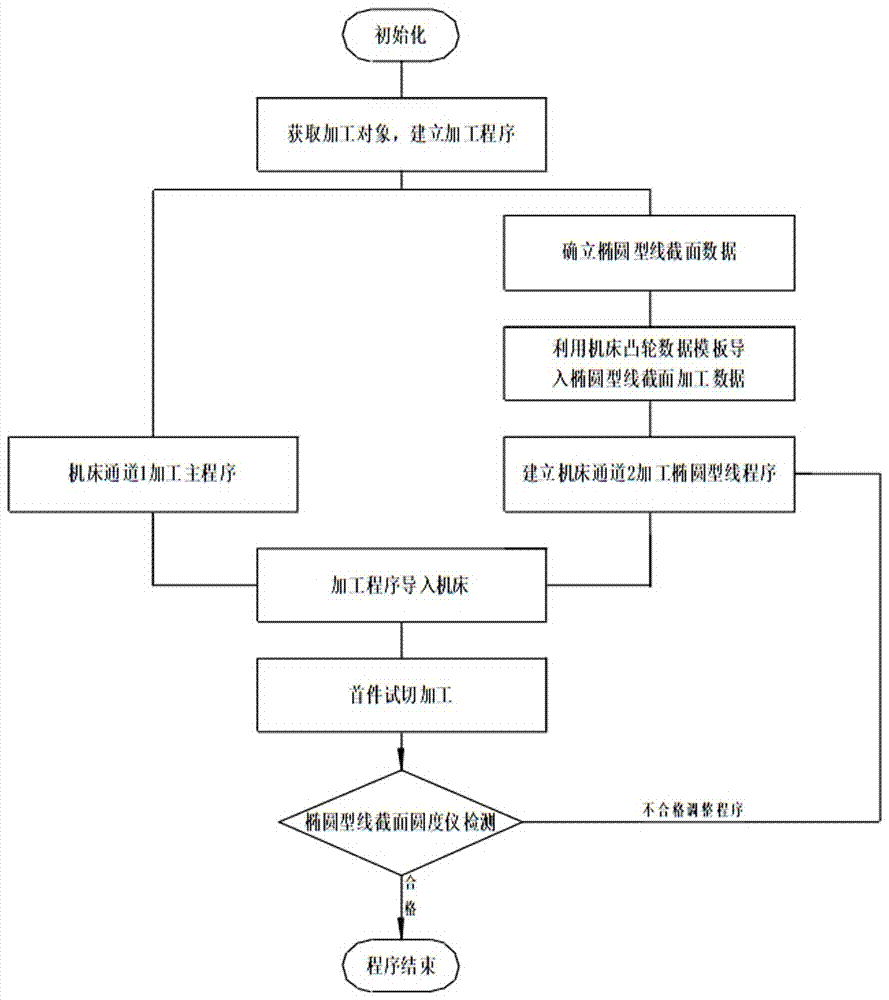

[0046] The lathe used in this embodiment is the omega80 model of British BsA Tools company. refer to figure 2 and 3 , introduce the machining process.

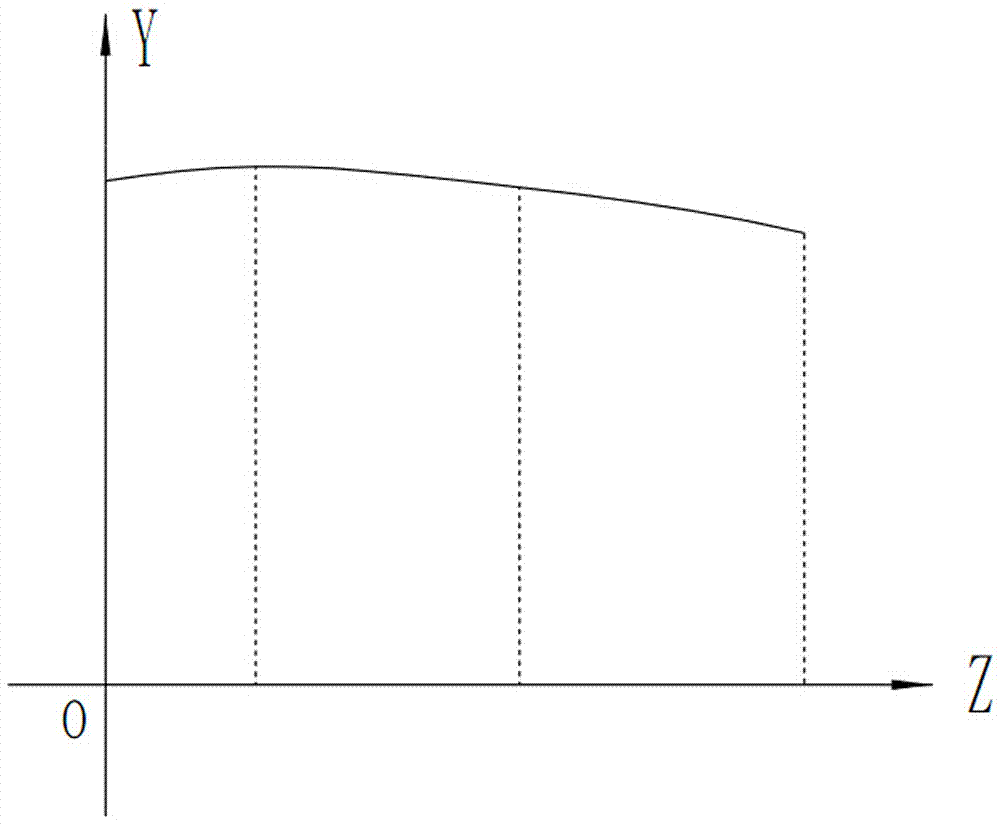

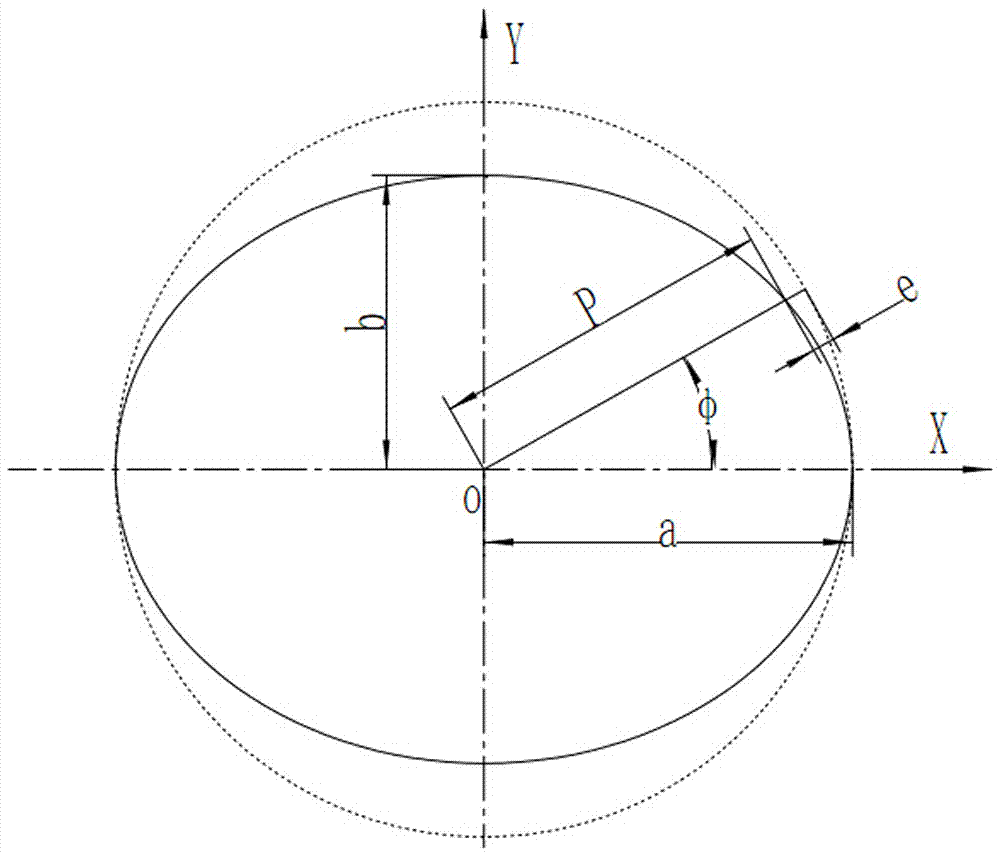

[0047] Step 1: The characteristic of the convex variable ellipse piston is that the cross section of the piston is similar to an ellipse shape, and the ellipticity values at different piston heights are different, and it is drum-shaped or convex in the longitudinal direction, and the piston becomes elliptical in shape. given by design drawings. As in the accompanying drawings figure 1 and 2 As shown, according to the ellipticity value at the height of the piston, the polar angle Φ between the ellipse shape line and the semi-major axis, and the reduction amount e are calculated. The cross-section is left-right and up-down symmetrical, and only needs to calculate the reduction amount from 0 to 90° (the first quadrant).

[0048] Reduction: e={SIN(Φ)*SIN(Φ)}*c / 2

[0049] The difference between the diameters of the major ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com