Material absorbing device used for producing automobile connector

A technology for automotive connectors and material suction devices, which is applied in the field of material suction devices, can solve the problems that the feeding barrel cannot be well sealed, the raw materials cannot be found in time, and the product quality is affected, and it is easy to maintain, save manpower, and has a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

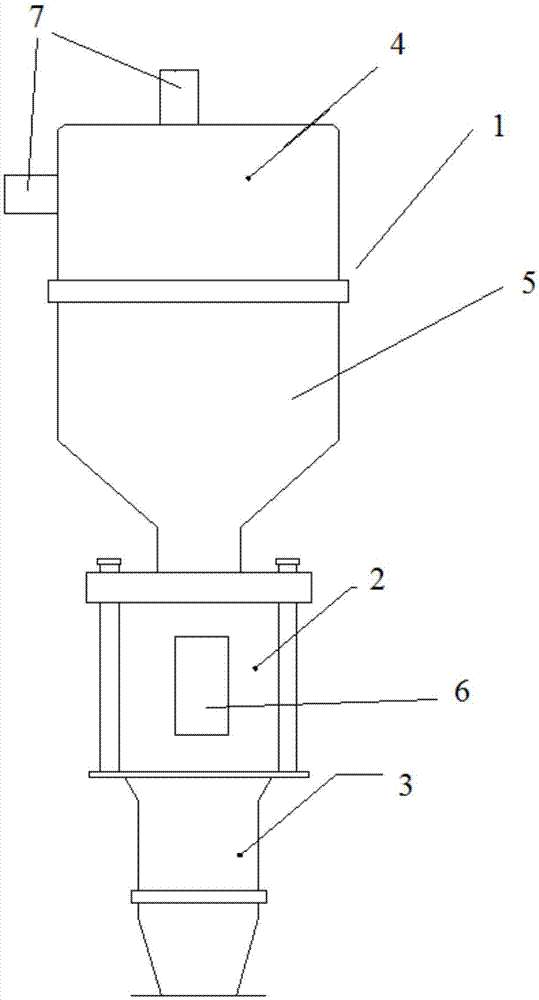

[0020] A material suction device for producing automotive connectors, its structure see figure 1 As shown, it includes a connected feeder and a container assembly, the feeder is also connected to a supply tank, and the container assembly includes a first container 1 and a second container 2 arranged in sequence from top to bottom, the first The container 1 and the second container 2 are sealed and connected by a flange structure. The first container 1 is composed of a split upper container 4 and a lower container 5. The upper container 4 and the lower container The container 5 is connected to form a clamshell structure, the upper container 4 is connected to the suction device through the feeding pipeline 7, and the second sensor for detecting whether the raw material of the upper container is filled is arranged on the top of the upper container 4, and the lower container 5 It is funnel-shaped, and a sealing ring is also provided at the connection between the upper container 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com