Preparation method of jun porcelain bluish-white glaze

A technology of Qingbai and Jun porcelain, applied in the field of glazes, can solve the problems of not being able to produce Qingbai glaze, and achieve the effect of rich glaze color and high artistic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method of Jun porcelain bluish-white glaze, comprising the following steps:

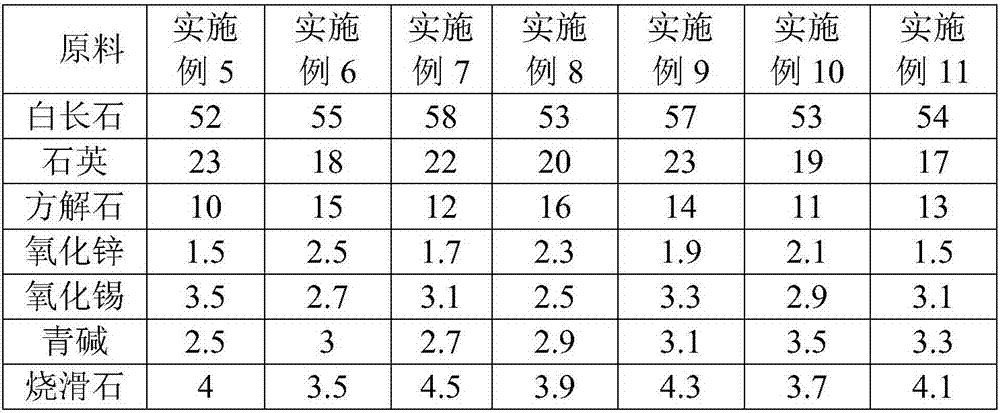

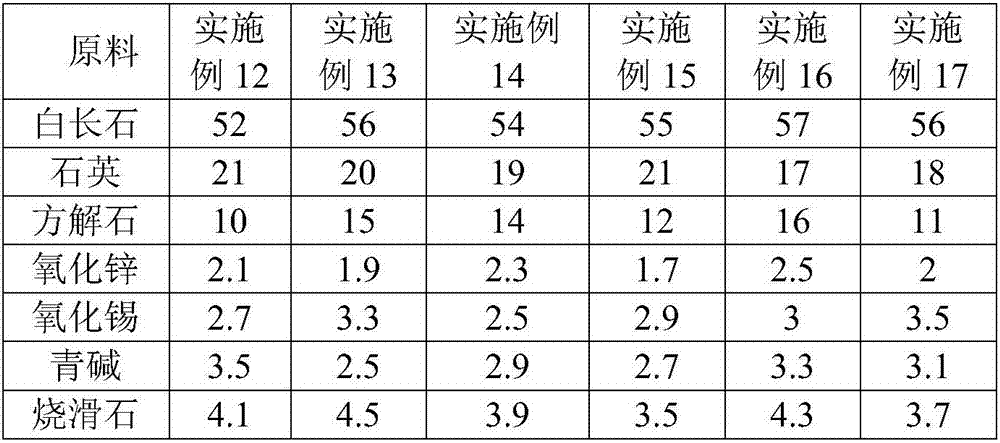

[0017] (1) Preparation of bottom glaze: Mix the following raw materials in parts by weight, 52-58 parts of white feldspar, 17-23 parts of quartz, 10-16 parts of calcite, 1.5-2.5 parts of zinc oxide, 2.5-3.5 parts of tin oxide, 2.5-3.5 parts of cyanine, 3.5-4.5 parts of calcined talc, ball milled; passed through a 200-mesh sieve, aged for 24 hours, to obtain the bottom glaze slurry;

[0018] (2) Apply the bottom glaze on the embryo body by dipping the glaze and dry it;

[0019] (3) Preparation of surface glaze: surface glaze is composed of two kinds of glazes, one is blue glaze, which is prepared from the following raw materials in parts by weight: 37-43 parts of white feldspar, 15-21 parts of quartz, 9 parts of this medicine -15 parts, 11-17 parts of calcite, 5.5-6.5 parts of copper ore, 7.5-8.5 parts of frit, 0.5-1.5 parts of copper oxide, 0.5-1.5 parts of tin oxide; the other ...

Embodiment 2

[0028] A preparation method of Jun porcelain bluish-white glaze, comprising the steps of:

[0029] (1) Preparation of the bottom glaze: mix the following raw materials in parts by weight, 55 parts of leiosite, 20 parts of quartz, 13 parts of calcite, 2 parts of zinc oxide, 3 parts of tin oxide, 3 parts of cyanine, and 4 parts of calcined talc; Ball milling; passing through a 200-mesh sieve and aging for 24 hours to obtain the bottom glaze slurry;

[0030] (2) Apply the bottom glaze on the embryo body by dipping the glaze and dry it;

[0031] (3) Preparation of surface glaze: surface glaze is made up of two kinds of glazes, and a kind of is blue glaze, is prepared from the raw material of following parts by weight: 40 parts of white feldspar, 18 parts of quartz, 12 parts of this medicine, 14 parts of calcite 1 part, 6 parts of copper ore, 8 parts of frit, 1 part of copper oxide, and 1 part of tin oxide. The other is red glaze, prepared from the following raw materials in part...

Embodiment 3

[0036] A preparation method of Jun porcelain bluish-white glaze, comprising the steps of:

[0037] (1) Preparation of the bottom glaze: mix the following raw materials in parts by weight, 55 parts of leiosite, 20 parts of quartz, 13 parts of calcite, 2 parts of zinc oxide, 3 parts of tin oxide, 3 parts of cyanine, and 4 parts of calcined talc; Ball milling; passing through a 200-mesh sieve and aging for 24 hours to obtain the bottom glaze slurry;

[0038] (2) Apply the bottom glaze on the embryo body by dipping the glaze and dry it;

[0039] (3) Preparation of surface glaze: surface glaze is made up of two kinds of glazes, and a kind of is blue glaze, is prepared from the raw material of following parts by weight: 40 parts of white feldspar, 18 parts of quartz, 12 parts of this medicine, 14 parts of calcite 1 part, 6 parts of copper ore, 8 parts of frit, 1 part of copper oxide, and 1 part of tin oxide. The other is red glaze, prepared from the following raw materials in part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com