Green-returning glaze for ceramic ornaments and preparation method thereof

A technology of Huiqing glaze and ornaments, applied in the field of ceramic glaze, can solve the problems of low yield and difficulty in blending color glazes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

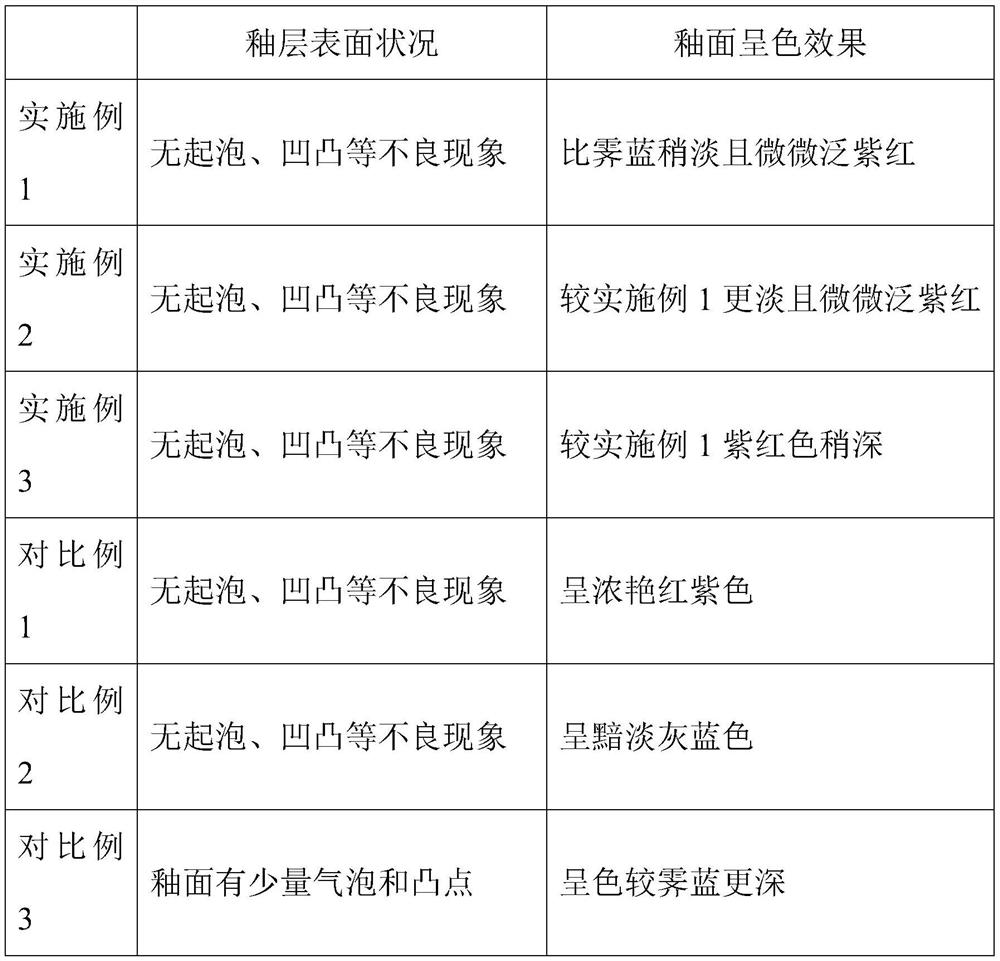

Examples

Embodiment 1

[0015] This embodiment discloses a green glaze used for ceramic ornaments, and the preparation steps are as follows:

[0016] S1. Weigh the materials according to the frit formula: 9 parts of black wool soil, 0.6 parts of barium carbonate, 7 parts of talcum powder, 1.5 parts of zinc oxide, 4 parts of illite, mix well, melt at 1180 ° C, keep warm for 30 minutes, and put The temperature was lowered to 1000°C, kept for 30 minutes, then poured into cold water to quench into fine particles, dried, crushed, and ball milled through a 250-mesh sieve to obtain a frit for use;

[0017] S2. Weigh according to the green glaze formula: 14 parts of Yunnan soil, 2.9 parts of tin crystal material, 7.5 parts of pine ash, 1.8 parts of deep sea shell powder, 0.3 part of tricobalt tetroxide, 5.1 parts of white agate, 0.1 part of olivine, 6 parts of expanded perlite Parts, 18 parts of frit, with material: ball: water = 1:2:0.8, put into ball mill and grind for 5 hours, and sieve the remaining 0.08...

Embodiment 2

[0019] This embodiment discloses a green glaze used for ceramic ornaments, and the preparation steps are as follows:

[0020] S1. Weigh the materials according to the frit formula: 10 parts of black wool soil, 0.5 parts of barium carbonate, 8 parts of talcum powder, 1.3 parts of zinc oxide, 3.6 parts of illite, mix well, melt at 1210 ° C, keep warm for 30 minutes, Lower the temperature to 960°C, keep it warm for 30 minutes, then pour cold water to quench it into fine particles, dry, crush, and ball mill through a 280-mesh sieve to obtain a frit for use;

[0021] S2. Weigh according to the blue glaze formula: 16 parts of Yunnan soil, 2.8 parts of tin crystal material, 7.7 parts of pine ash, 1.6 parts of deep sea shell powder, 0.1 part of tricobalt tetroxide, 5.4 parts of white agate, 0.08 parts of olivine, 5 parts of expanded perlite Parts, 18 parts of frit, with material: ball: water = 1:2:0.7, put into ball mill and grind for 7 hours, and sieve the remaining 0.08% through 250...

Embodiment 3

[0023] This embodiment discloses a green glaze used for ceramic ornaments, and the preparation steps are as follows:

[0024] S1. Weigh the materials according to the frit formula: 9 parts of black wool soil, 0.7 parts of barium carbonate, 7 parts of talcum powder, 1.5 parts of zinc oxide, 4.2 parts of illite, mix well, melt at a temperature of 1200 ° C, keep warm for 30 minutes, and put The temperature was lowered to 980°C, kept for 30 minutes, then poured into cold water to quench into fine particles, dried, crushed, and ball milled through a 280-mesh sieve to obtain a frit for use;

[0025] S2. Weigh according to the green glaze formula: 14 parts of Yunnan soil, 2.9 parts of tin crystal material, 7.5 parts of pine ash, 1.8 parts of deep sea shell powder, 0.4 part of tricobalt tetroxide, 4.9 parts of white agate, 0.12 parts of olivine, 6 parts of expanded perlite Parts, 18 parts of frit, with material: ball: water = 1:2:0.75, put into ball mill and grind for 6 hours, and sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com