A method for producing highland barley health wine by pretreatment and then fermentation

A re-fermentation and pretreatment technology, applied in microorganism-based methods, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problem of being easily affected by external environmental factors, limited industrialization and application, and different product performance. and other problems to achieve the effect of improving the utilization rate of raw materials, enriching the flavor and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

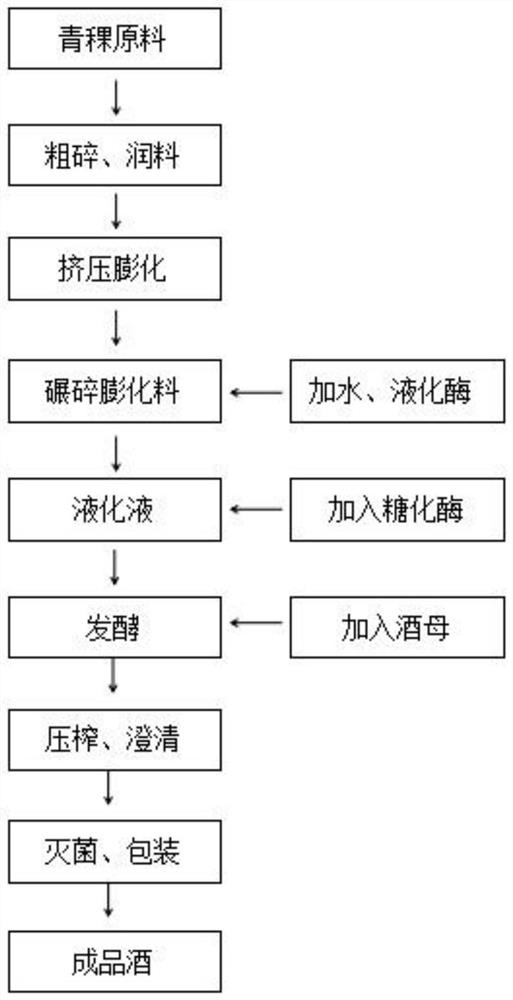

Method used

Image

Examples

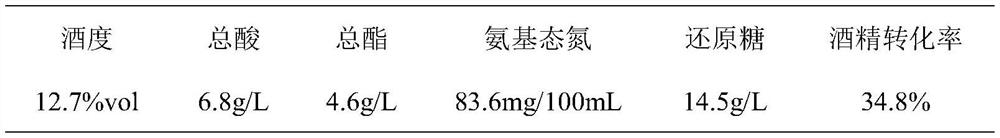

Embodiment 1

[0033] Step 1: coarsely crush the highland barley raw material before puffing, add hydrating material, stir evenly, adjust the water content of the material to 24%, and use an extruder to puff the highland barley raw material. The puffing conditions are extrusion die hole diameter 5-10mm, puffing temperature 180°C, extrusion screw speed 240r / min, to obtain expanded material.

[0034] Step 2: Grind the puffed material and add a certain amount of water to moisten the material. The ratio of material to water is 1:3, and stir evenly; after fully moistening the material, keep the temperature at 65°C, add α-amylase 100U / g, At the same time, 80 u / g of β-glucanase was added, and the pH of enzymolysis was 5.0-6.0 to carry out liquefaction and enzymolysis of the fermentation raw materials, and the enzymolysis time was 120 minutes. The method to detect the end point of liquefaction is to mix the iodine solution with the liquefaction liquid, if it shows orange yellow or reddish brown, the...

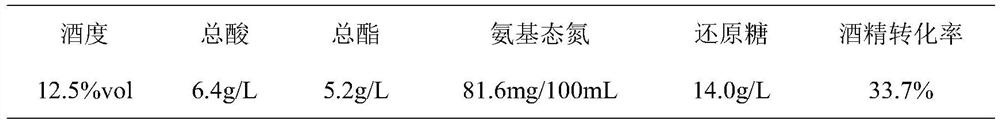

Embodiment 2

[0043] Step 1, first wash the highland barley clean, add water to moisten the material until the water content of the material is 24%, and use the puffing machine to puff the highland barley raw material. min, to obtain puffed material.

[0044] Step 2: Grind the puffed material and add a certain quality of water to moisten the material. The ratio of material to water is 1:2.8, and stir evenly; after fully moistening the material, keep the temperature at 65°C, add α-amylase 100U / g, and perform enzymatic hydrolysis pH 5.0-6.0, carry out liquefaction and enzymolysis of fermentation raw materials, the enzymolysis time is 120min. The method of detecting the liquefaction end point is to mix the iodine solution with the liquefaction liquid. If it shows orange yellow or reddish brown, the liquefaction end point is reached; then keep the temperature at 55°C, add glucoamylase, the dosage of glucoamylase is 160U / g, and the reaction time is 120min.

[0045] Step 3: Activate the active d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com