Low-noise rotary capture absorption type oil-gas separator

An oil and gas separator, adsorption technology, applied in the direction of machine/engine, engine components, mechanical equipment, etc., can solve the problem of increasing the decibel value of engine noise, and achieve the effect of reducing aerodynamic noise and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, innovative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

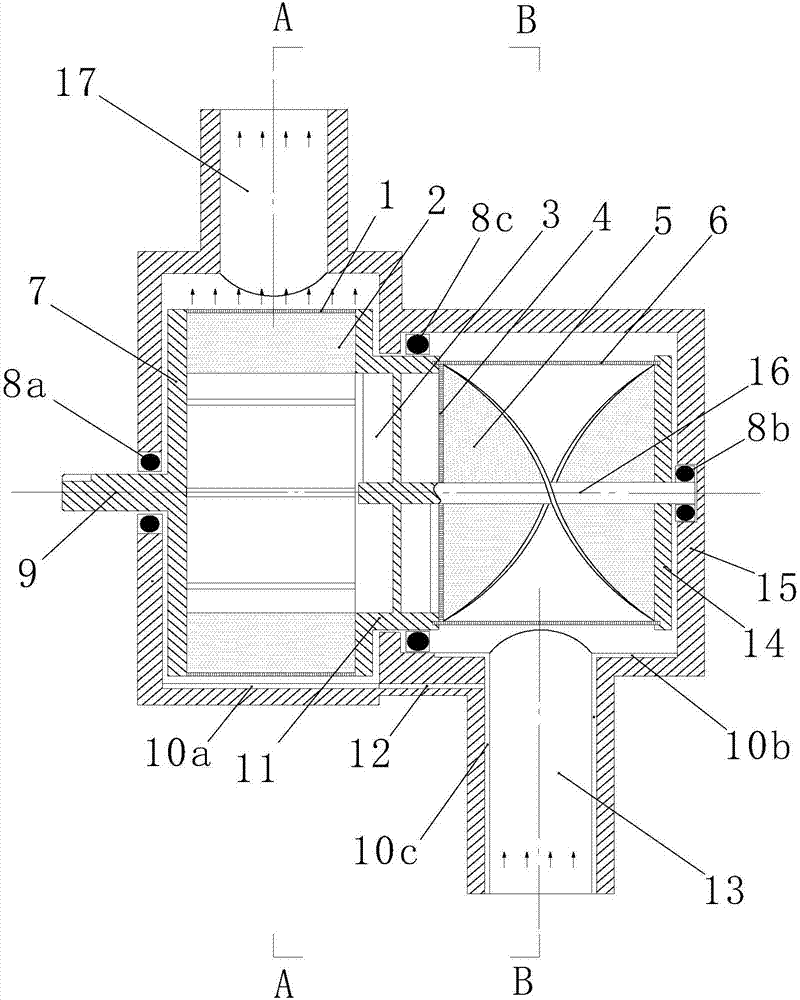

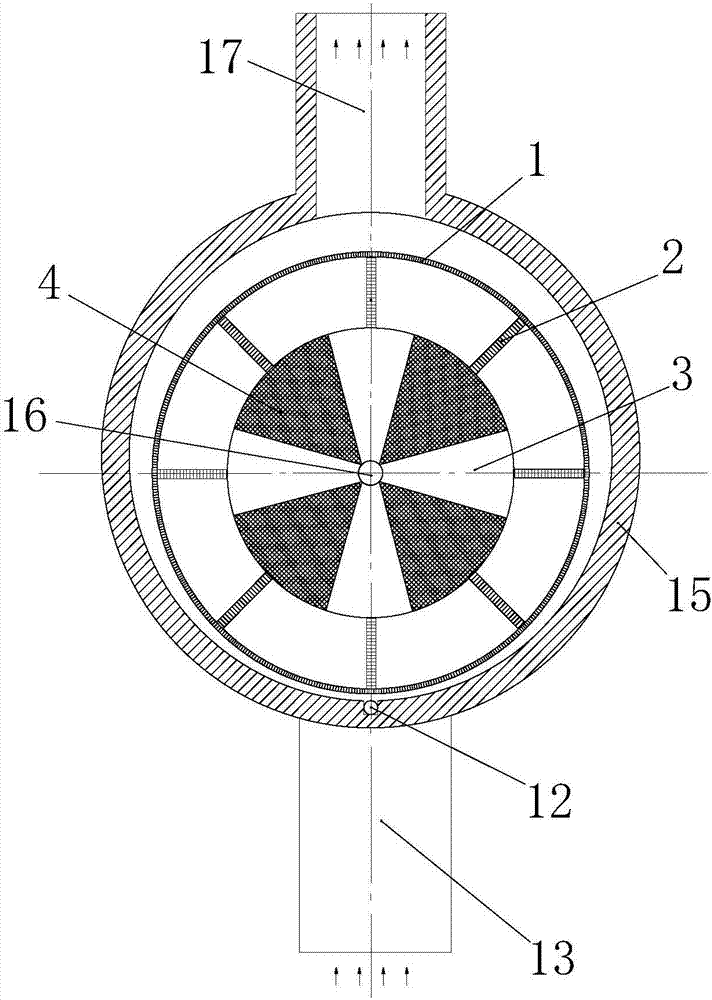

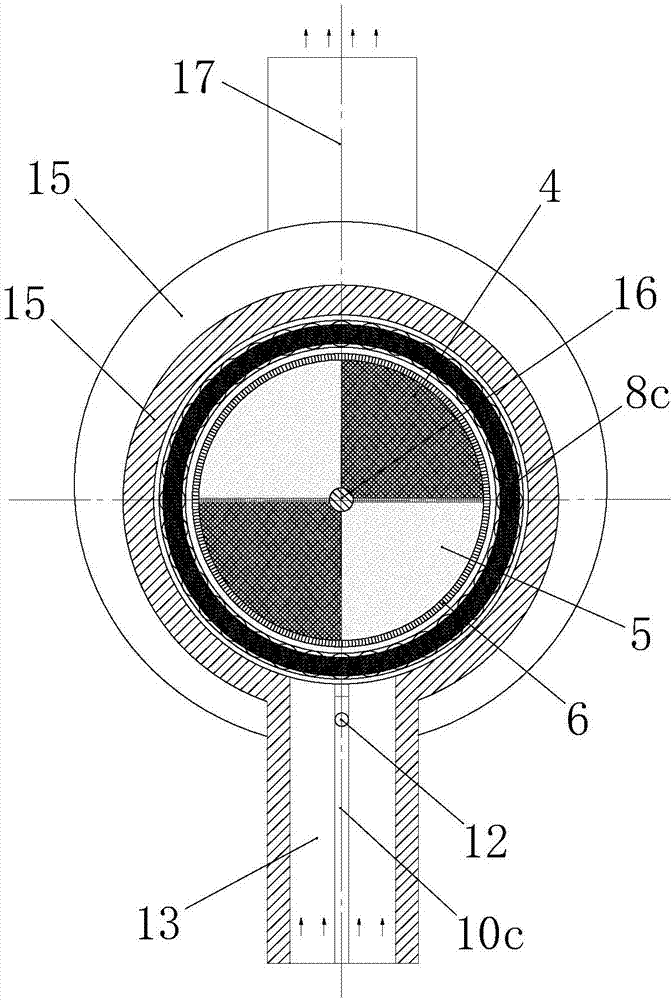

[0022] like Figure 1-Figure 3 As shown, a low-noise rotary capture adsorption oil-gas separator, it includes a housing 15, the housing 15 is provided with an inlet pipe 13 and an air outlet pipe 17, and one end of the housing 15 is equipped with a driven shaft 9 , the driven shaft 9 extends out of the housing 15 through the sealed bearing 8a, and a turntable 7 is provided at the other end of the driven shaft 9; a central rotating shaft 16 is also provided in the housing 15, and the central rotating shaft One end of 16 is provided with an axial fan blade 3 connected to the connecting pipe 11, and the other end is provided with a tray 14 and connected with the inner ring of the sealed bearing 8b;

[0023] A sealed bearing 8c is provided betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com