Pressure expander blade, compressor structure and compressor

A diffuser and compressor technology, applied in the field of compressors, can solve the problems of airflow mixing loss, reduce the aerodynamic efficiency of the compressor, and the large low-speed and low-energy area of the blade, so as to reduce the airflow mixing loss and improve the aerodynamic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

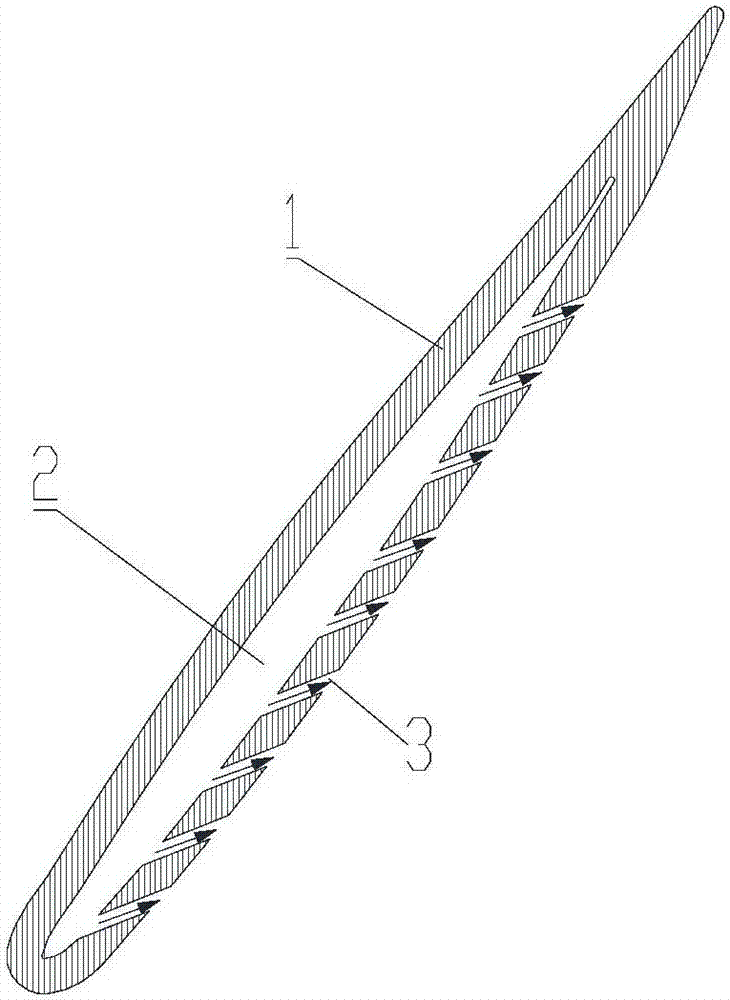

[0023] The purpose of the invention is to reduce the air mixing loss caused by supplementary air, and expand the operating range of the compressor while improving the performance of the design point. To this end, the embodiment of the present invention provides a diffuser vane, comprising: a vane body 1 , a cavity 2 is formed inside the vane body 1 , and an air supply hole 3 is formed on the vane body 1 . Preferably, the air supply holes 3 are arranged on the suction surface of the blade body 1 . Preferably, the blade body 1 is made by casting or machining.

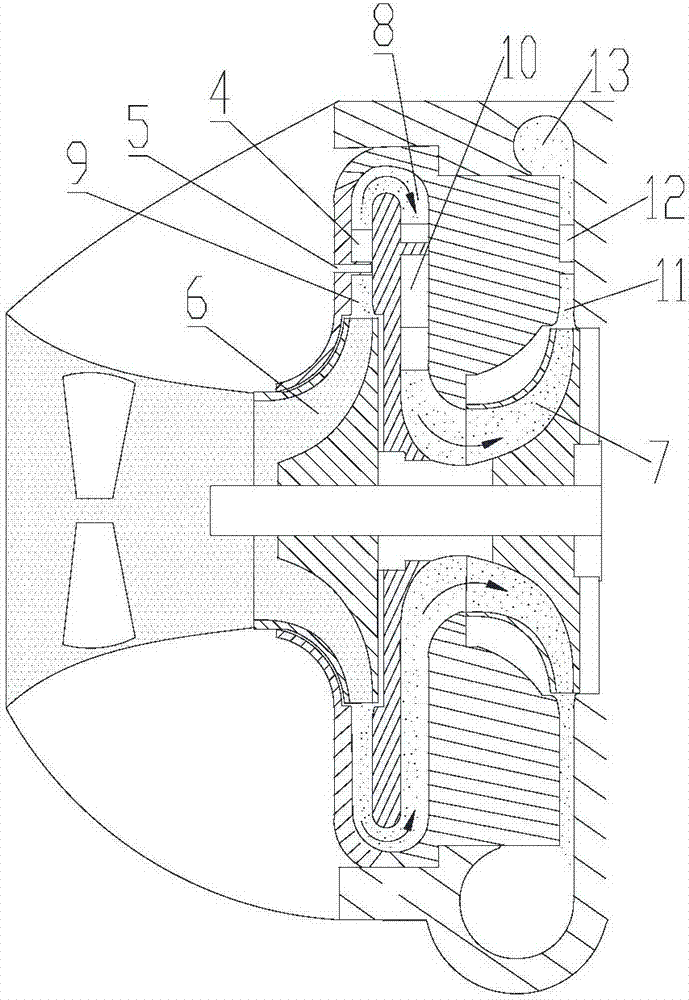

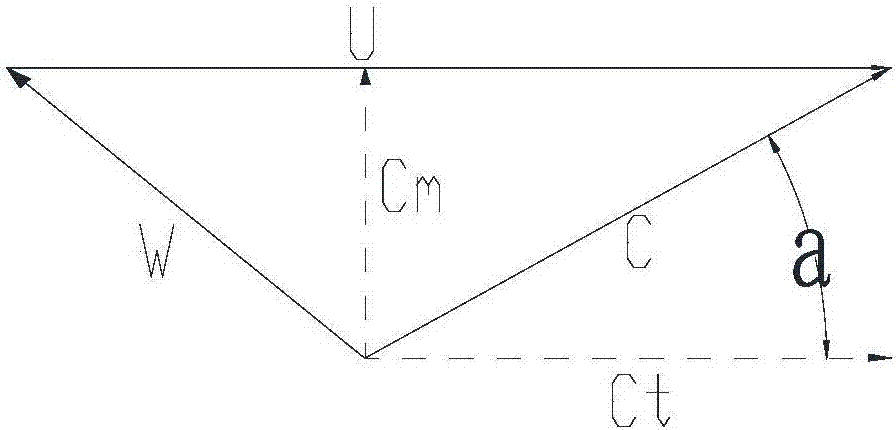

[0024] Please refer to Figure 1-3 , when the compressor is running at the design point, after the gas refrigerant passes through the first-stage impeller 6, since the refrigerant moves in a circle with the impeller, the absolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com