Design for transonic axial fan blade angular seam casing treatment structure

A technology of axial flow fan and structural design, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., and can solve the problems of weak expansion stability and large efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This embodiment is a design of a transonic axial flow fan blade angular seam casing processing structure.

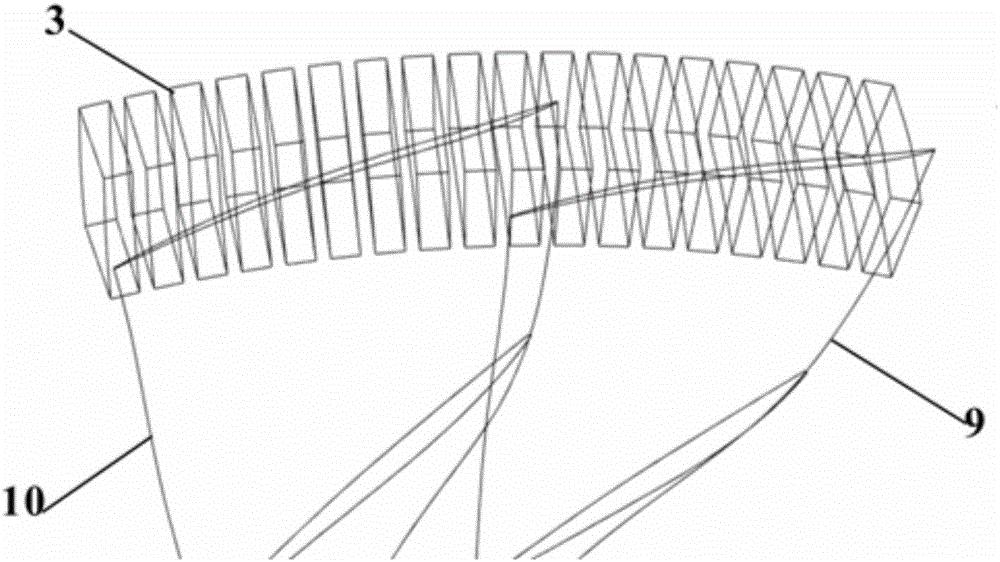

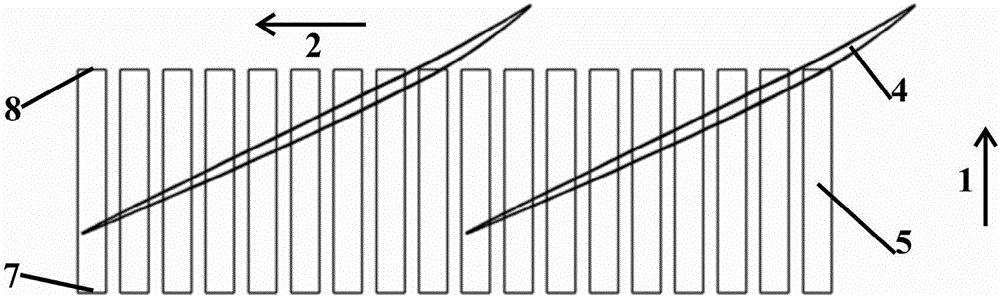

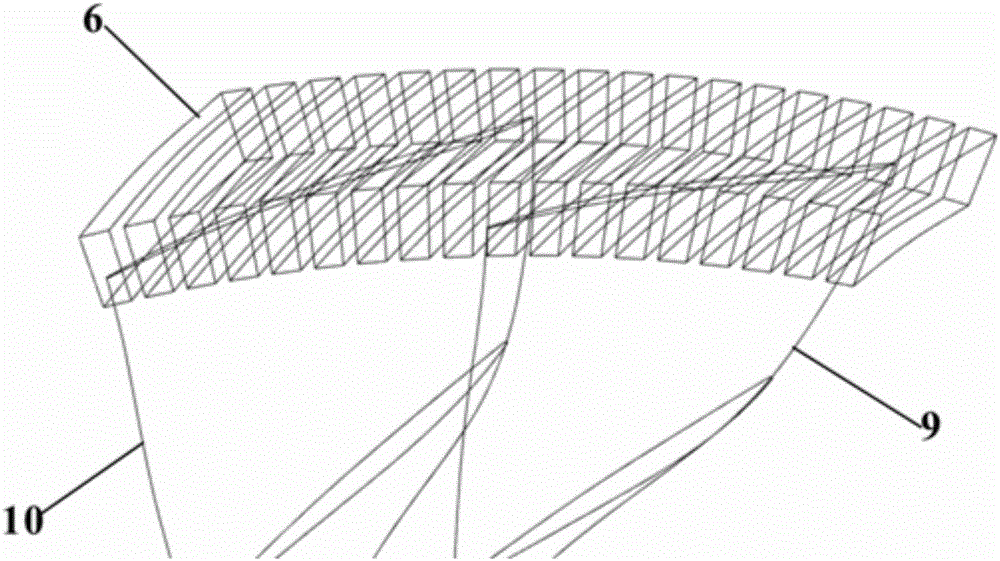

[0017] refer to Figure 1 ~ Figure 4 In this embodiment, the design of the treatment structure of the transonic axial flow fan blade angular seam casing includes the axial seam casing processing structure and the blade angular seam casing processing structure; it has a plurality of holes along the axial direction on the fan casing Narrow slots are evenly arranged along the circumferential direction to form an axial slot casing processing structure 3, and the width of the axial slot casing processing structure 3 covers the entire axial chord length of the blade tip 4. The opening surface 5 of the axial seam casing processing structure 3 is rotated at a certain angle along the blade installation angle direction to form a blade angular seam casing processing structure 6, and the direction of air bleed and air injection of the blade angular seam casing processing stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com