A technology of imitating jacquard for imitation wax printing fabric

A fabric and printing technology, applied in the direction of digging fabrics, processing textile material carriers, spraying/jetting textile materials, etc., can solve the problems of difficult control of fabric tension, reduced fabric steaming efficiency, high production costs, etc., to increase Drying effect, improving steaming effect, increasing air flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

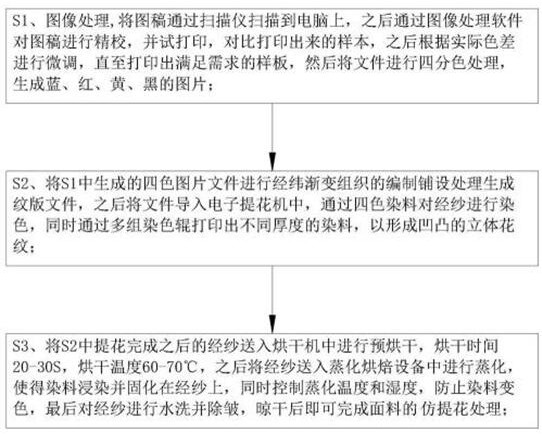

Method used

Image

Examples

Embodiment approach

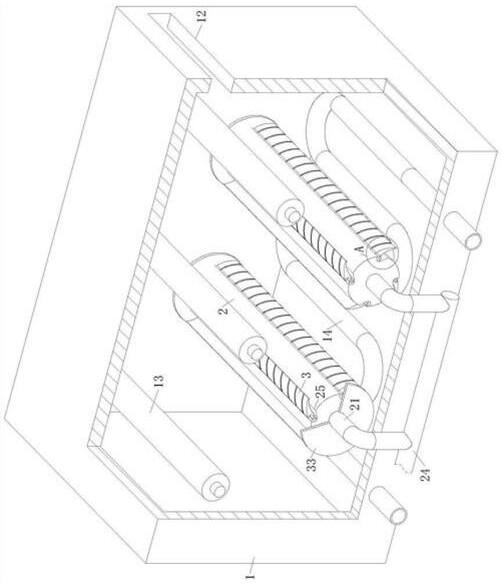

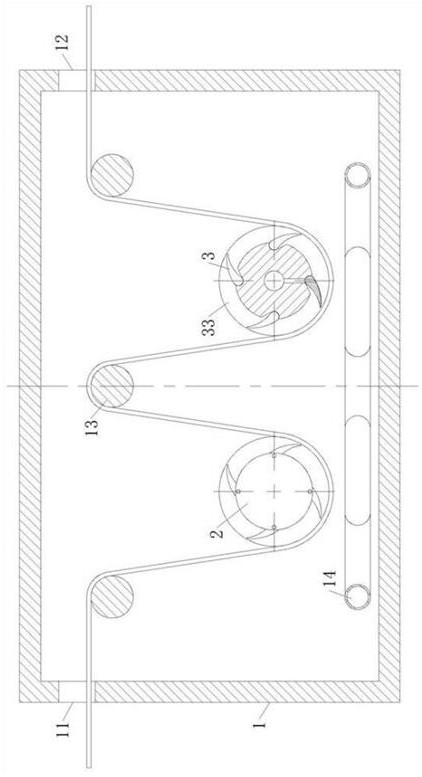

[0034] As an embodiment of the present invention, the No. 2 hole 23 is arranged vertically downward, and the No. 2 hole 23 communicates with the bottom of the groove 25; 3 is provided with a group of No. 3 holes 31; when the arc-shaped plate 3 rotates counterclockwise and approaches the tension roller 2, No. 3 holes 31 communicate with No. 2 holes 23; Water vapor increases the utilization efficiency of water vapor, further increases the steaming efficiency of the fabric, and improves the coloring quality of the fabric; when the arc-shaped plate 3 rotates counterclockwise with the tension roller 2 and contacts the fabric, the fabric squeezes the arc-shaped plate 3 Make the arc-shaped plate 3 rotate and squeeze the spring 26. After the arc-shaped plate 3 rotates, the third hole 31 communicates with the second hole 23, so that the high-temperature water vapor in the first hole 22 passes through the second hole 23 and then flows from the third hole. The holes 31 are ejected downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com