Parallel type pulse tube machine

A parallel, pulse tube technology, applied in refrigerators, compressors, gas cycle refrigerators, etc., can solve the problems of reducing economic costs, complex and disadvantageous structure of refrigerators, improve work efficiency, and avoid uneven temperature distribution. , the effect of increasing the cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

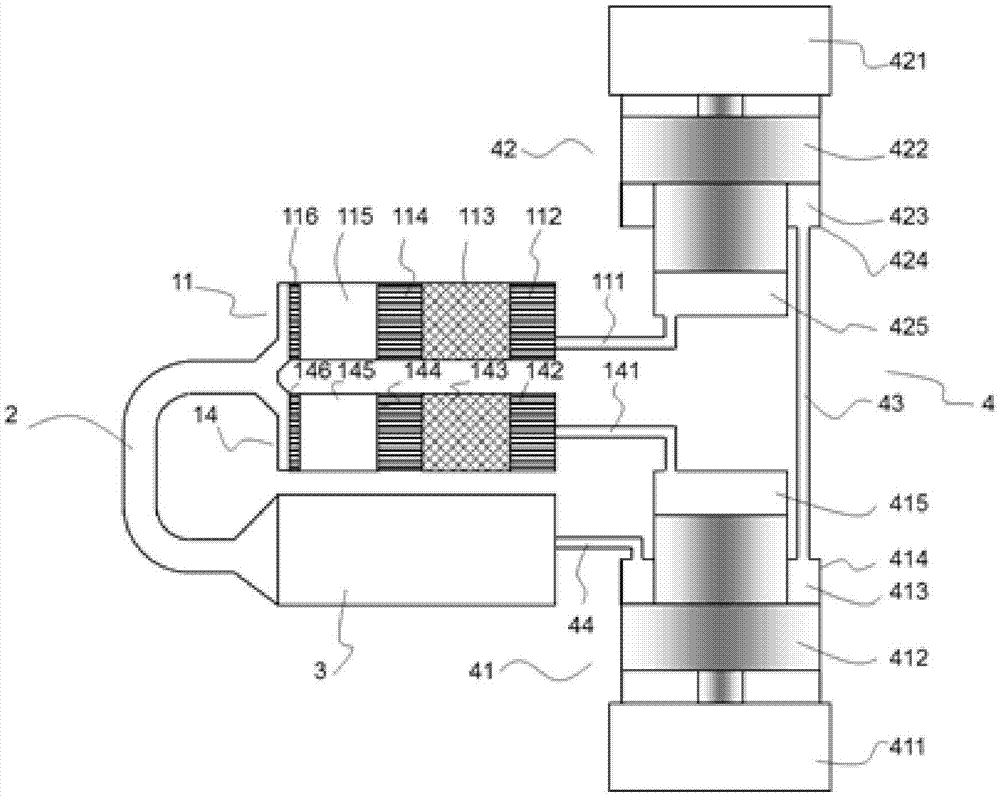

Embodiment 1

[0036] Such as figure 1 As shown, the parallel pulse tube refrigerator is composed of a cold head 11, a cold head 14, an inertia tube 2, a gas storage 3 and a compressor 4. The compressor 4 is composed of a stepped compressor 41 , a stepped compressor 42 , a second connecting pipe 43 and a connecting pipe 44 .

[0037] The cold head 11 is formed by connecting the first connecting pipe 111, the hot end heat exchanger 112, the regenerator 113, the cold end heat exchanger 114, the pulse tube 115 and the pulse tube hot end heat exchanger 116 in sequence, and the gas can be Free flow within each part.

[0038] The cold head 14 is formed by connecting the first connection pipe 141, the hot end heat exchanger 142, the regenerator 143, the cold end heat exchanger 144, the pulse tube 145 and the pulse tube hot end heat exchanger 146 in sequence, and the gas can be Free flow within each part.

[0039] The cold head 11 and the cold head 14 are connected to the inertia tube 2 and the gas...

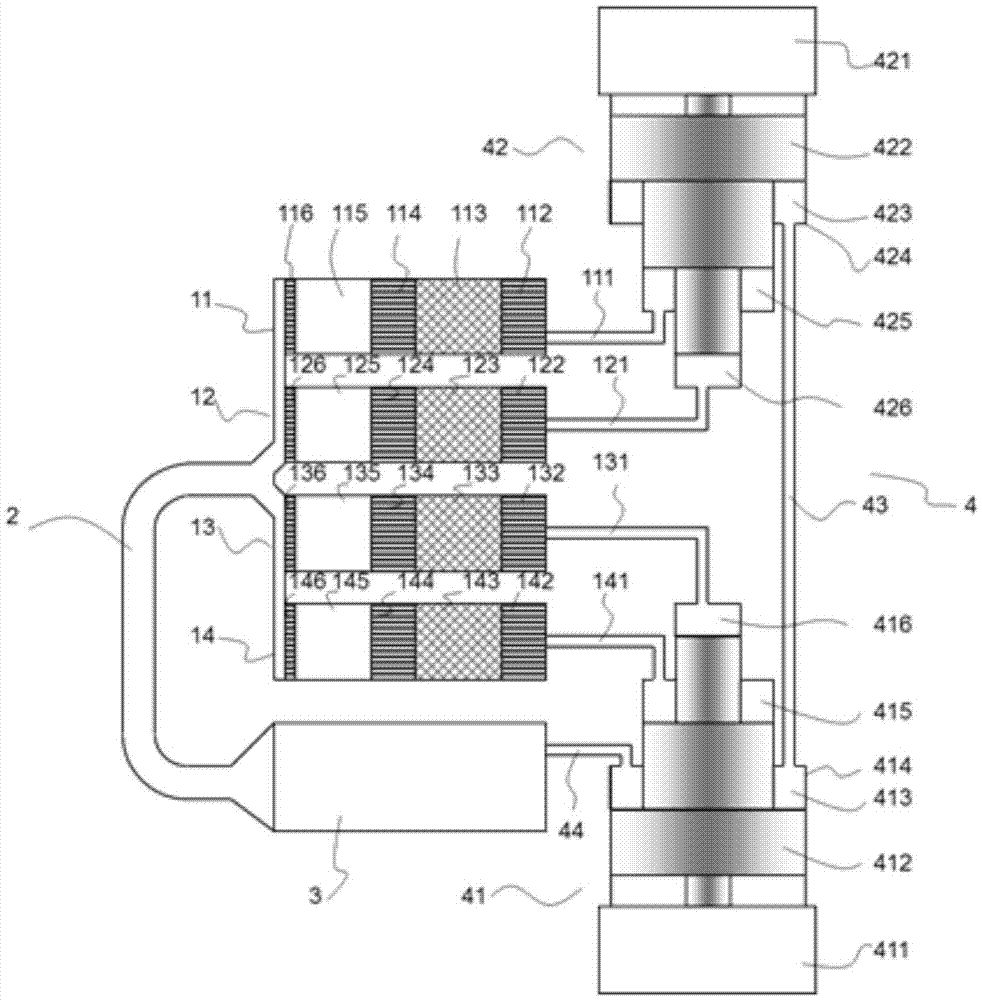

Embodiment 2

[0044] Such as figure 2 As shown, in the parallel pulse tube refrigerator, on the basis of Embodiment 1, the n-stage stepped piston 412 and the n-stage stepped piston 422 are respectively increased by one step. Correspondingly, the stepped compressor 41 and the stepped compressor 42 are respectively The compression chamber 416 and the compression chamber 426 are added, and the cold head 12 and the cold head 13 are added correspondingly.

[0045] Wherein, the cold head 12 is formed by sequentially connecting the first connecting pipe 121, the hot end heat exchanger 122, the regenerator 123, the cold end heat exchanger 124, the pulse tube 125 and the pulse tube hot end heat exchanger 126. Can flow freely in all parts.

[0046] The cold head 13 is connected in sequence by the first connecting pipe 131, the hot end heat exchanger 132, the regenerator 133, the cold end heat exchanger 134, the pulse tube 135 and the pulse tube hot end heat exchanger 136. Free flow within each par...

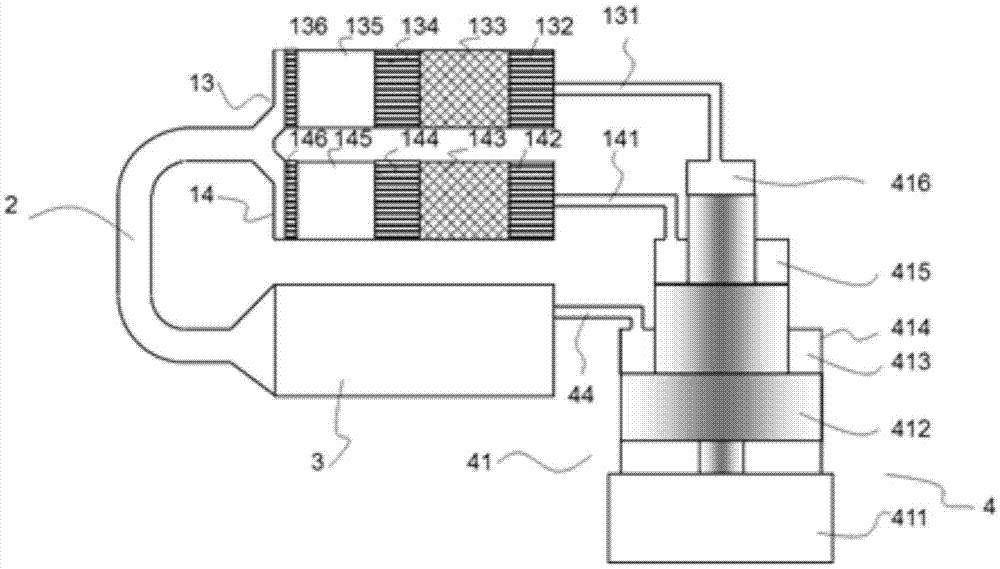

Embodiment 3

[0049] Such as image 3 As shown, in the parallel pulse tube refrigerator, two two-stage stepped compressors are replaced with a three-stage stepped compressor on the basis of Embodiment 1, so in this embodiment, the stepped compressor 41 has a compression chamber 415 And the compression chamber 416 and the expansion chamber 413, and the cold head 13 and the cold head 14 are driven by the compression chamber 415 and the compression chamber 416. The compression chamber 415 communicates with the cold head 14 through the first connecting pipe 141, and the compression chamber 416 passes through the first The connecting pipe 131 communicates with the cold head 13 .

[0050] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com