Switch cabinet having dust removing function

A switchgear, functional technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

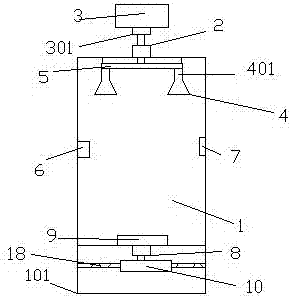

Embodiment 1

[0026] see figure 1 , this embodiment relates to a switch cabinet with a dust removal function, including a cabinet body 1, the cabinet body 1 is arranged on a base 101, an outlet-2 is provided on the top of the cabinet body 1, and an empty space is provided above the outlet-2. Compressor 3, the inner wall of the cabinet body 1 is provided with a plurality of nozzles 4, the air inlet 401 of the nozzle 4 is connected to the air outlet 301 of the air compressor 3 through the pipeline 5 passing through the outlet one 2, the The inside of the cabinet body 1 is provided with a dust monitoring device 6 and a controller 7, the bottom of the cabinet body 1 is provided with an outlet 2 8, and the upper part of the outlet 8 is provided with a vacuum cleaner 9, and the vacuum cleaner 9 passes through the pipeline 5 passing through the outlet 2 8 It is connected to the dust storage box 10 located below the outlet 2 8, and the controller 7 is respectively connected to the air compressor 3,...

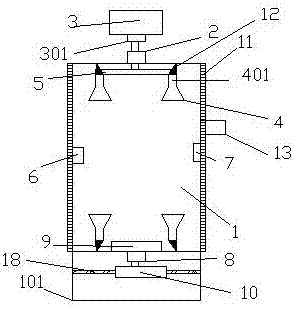

Embodiment 2

[0030] see figure 2 , this embodiment relates to a switch cabinet with a dust removal function, including a cabinet body 1, the cabinet body 1 is arranged on a base 101, and the top of the cabinet body 1 is provided with an outlet-2, and the outlet-2 An air compressor 3 is arranged above, and a plurality of nozzles 4 are arranged on the inner wall of the cabinet 1, and the air inlet 401 of the nozzle 4 and the air outlet 301 of the air compressor 3 pass through the pipeline 5 passing through the outlet one 2 connected, the inside of the cabinet 1 is provided with a dust monitoring device 6 and a controller 7, the bottom of the cabinet 1 is provided with an outlet 2 8, and the upper part of the outlet 8 is provided with a vacuum cleaner 9, and the vacuum cleaner 9 passes through the outlet 2 The pipeline 5 of 8 is connected to the dust storage box 10 located below the outlet 2 8, and the controller 7 is respectively connected to the air compressor 3, the dust monitoring device...

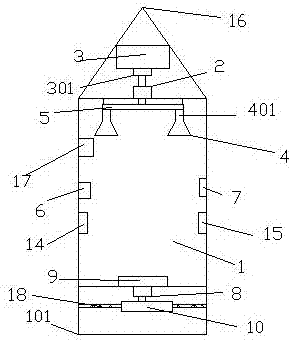

Embodiment 3

[0040] see image 3 , this embodiment relates to a switch cabinet with a dust removal function, including a cabinet body 1, the cabinet body 1 is arranged on a base 101, and the top of the cabinet body 1 is provided with an outlet-2, and the outlet-2 An air compressor 3 is arranged above, and a plurality of nozzles 4 are arranged on the inner wall of the cabinet 1, and the air inlet 401 of the nozzle 4 and the air outlet 301 of the air compressor 3 pass through the pipeline 5 passing through the outlet one 2 connected, the inside of the cabinet 1 is provided with a dust monitoring device 6 and a controller 7, the bottom of the cabinet 1 is provided with an outlet 2 8, and the upper part of the outlet 8 is provided with a vacuum cleaner 9, and the vacuum cleaner 9 passes through the outlet 2 The pipeline 5 of 8 is connected to the dust storage box 10 located below the outlet 2 8, and the controller 7 is respectively connected to the air compressor 3, the dust monitoring device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com