A kind of monolayer molybdenum disulfide-zinc ferrite nanocomposite material and its preparation method and application

A nano-composite material, single-layer molybdenum disulfide technology, which is applied in the fields of wave energy or particle radiation treatment materials, pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve problems such as rare research reports, achieve low energy consumption, The effect of low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of aminated molybdenum disulfide

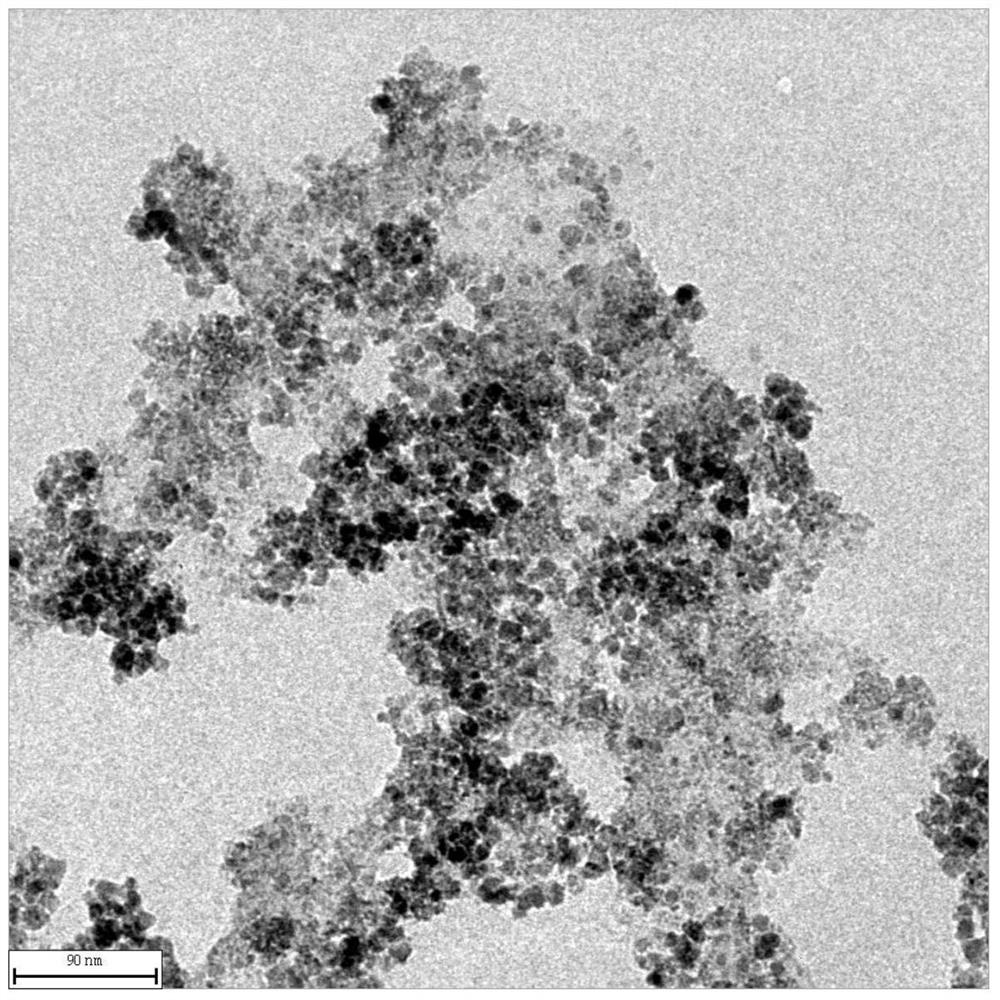

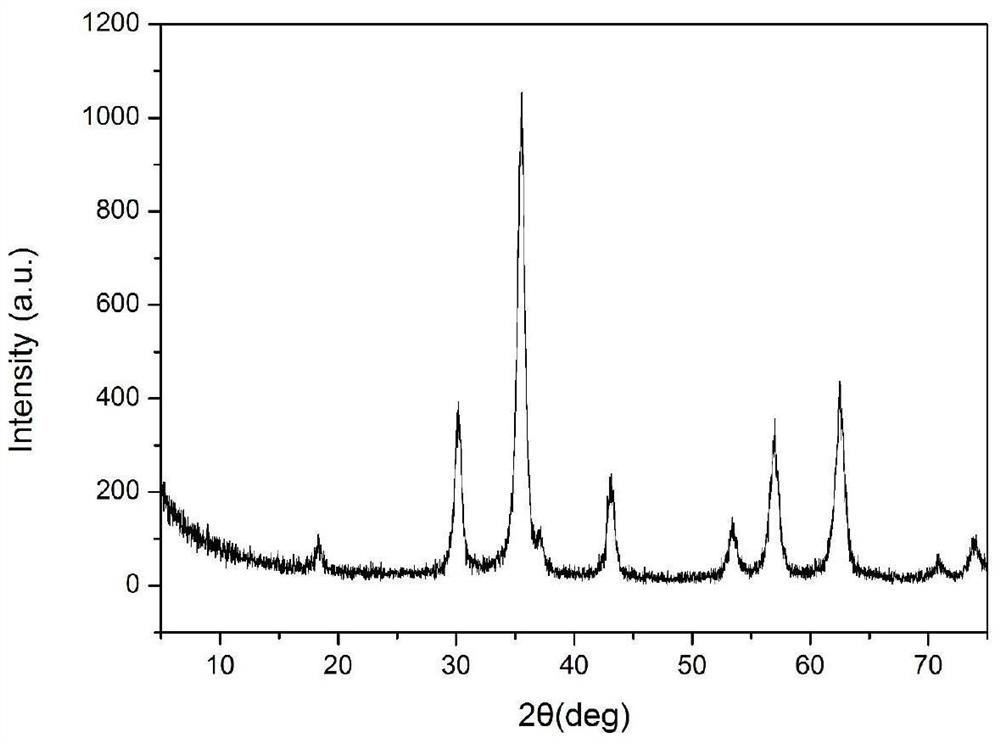

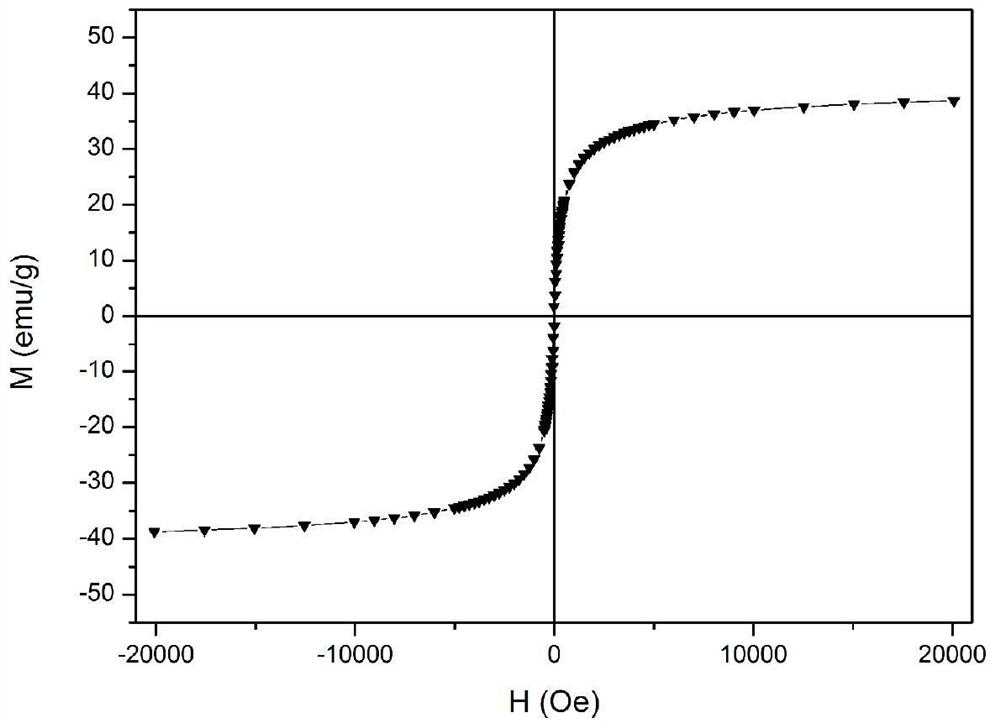

[0035] Put 10g commercial molybdenum disulfide powder and 750mL deionized water into a 1000mL three-necked flask, place it in a low-power ultrasonic tank, and vibrate ultrasonically for 6h; the reaction product is washed three times with deionized water, collected by centrifugation, and then dried in vacuum Dry in an oven for 24 hours to obtain molybdenum disulfide nanosheets; take 0.25g of vacuum-dried molybdenum disulfide nanosheets and disperse in 200mL deionized water, add 0.25g γ-aminopropyltriethoxysilane, ultrasonically shake for 2h, and centrifuge. , Washed three times with anhydrous ethanol and dried in a vacuum drying oven for 24 hours to obtain aminated molybdenum disulfide;

[0036] (2) Preparation of carboxylated zinc ferrite nanoparticles

[0037] In a 1000mL three-necked flask, 12.12gFe(NO 3 ) 3 ·9H 2 O and 4.46gZn(NO 3 ) 2 ·6H 2 Dissolve O in 750mL deionized water, bubbling with nitrogen for 30min, stir it eve...

Embodiment 2

[0041] (1) Preparation of aminated molybdenum disulfide

[0042] Add 5.0 g of commercial molybdenum disulfide powder and 750 mL of deionized water to a 1000 mL three-necked flask, place it in a low-power ultrasonic tank, and vibrate ultrasonically for 6 hours; the reaction product is washed three times with deionized water, collected by centrifugation, and then placed in vacuum Dry in a drying box for 24 hours to obtain molybdenum disulfide nanosheets; take 0.25g of vacuum-dried molybdenum disulfide nanosheets and disperse in 200mL deionized water, add 0.25g γ-aminopropyltriethoxysilane, ultrasonically shake for 2h and centrifuge Separate, wash with anhydrous ethanol and alcohol three times, and place it in a vacuum drying oven for 24 hours to obtain aminated molybdenum disulfide;

[0043] (2) Preparation of carboxylated zinc ferrite nanoparticles

[0044] In a 1000mL three-necked flask, 12.12gFe(NO 3 ) 3 ·9H 2 O and 4.46gZn(NO 3 ) 2 ·6H 2 Dissolve O in 750mL deionized water, bubbli...

Embodiment 3

[0048] (1) Preparation of aminated molybdenum disulfide

[0049] Put 5g commercial molybdenum disulfide powder and 750mL deionized water into a 1000mL three-necked flask, place it in a low-power ultrasonic tank, and vibrate ultrasonically for 6 hours; the reaction product is washed three times with deionized water, collected by centrifugation, and then dried in vacuum Dry in an oven for 24 hours to obtain molybdenum disulfide nanosheets; take 0.25g of vacuum-dried molybdenum disulfide nanosheets and disperse in 200mL deionized water, add 0.25g γ-aminopropyltriethoxysilane, ultrasonically shake for 2h, and centrifuge. , Washed three times with anhydrous ethanol and dried in a vacuum drying oven for 24 hours to obtain aminated molybdenum disulfide;

[0050] (2) Preparation of carboxylated zinc ferrite nanoparticles

[0051] In a 1000mL three-necked flask, 12.12gFe(NO 3 ) 3 ·9H 2 O and 4.46gZn(NO 3 ) 2 ·6H 2 Dissolve O in 750mL deionized water, bubbling with nitrogen for 30min, stir it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com