A kind of preparation method and application of nanometer nickel-based CO methanation catalyst

A methanation catalyst and nano-nickel technology, which is applied in the field of preparation of nano-nickel-based methanation catalysts, can solve the problems of reducing the utilization rate of active centers, hindering the mass transfer and diffusion of reactants, and being expensive, so as to achieve easy large-scale industrial production, Improved methanation performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

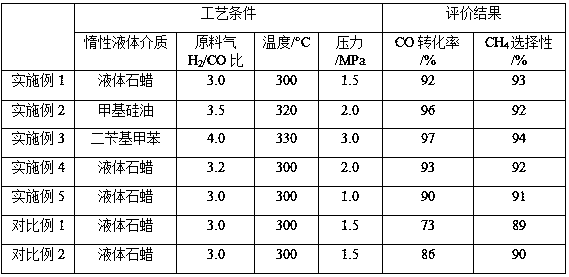

Examples

Embodiment 1

[0027] Dissolve 5 parts of nickel nitrate hexahydrate and 0.6 parts of zirconyl nitrate dihydrate in 65 parts of 60% aqueous solution of glycerol and start vigorous stirring at room temperature, then slowly add 5 parts of silica carrier to the solution , continue to stir and heat up to 70 ° C for ultrasonic treatment for 3 h, then move into a vacuum drying oven at 240 ° C for 6 h, then put the sample into a tube furnace and feed nitrogen at 450 ° C for 2 h. After nitrogen was switched to air, it was roasted at this temperature for another 2 h, and finally the samples obtained after roasting were ground and granulated to 80-200 mesh. In a fixed bed, the reduction temperature is 550 °C and the volume composition is 25%H 2 / 75%N 2 and space velocity of 6000 mL / (g·h) for 4 h to obtain the methanation nickel-based catalyst. The catalyst composition is: Ni 16wt%, ZrO 2 4 wt%, SiO 2 80 wt%.

[0028]The methanation performance of the catalyst was evaluated in a slurry bed metha...

Embodiment 2

[0031] Dissolve 7.6 parts of nickel acetate tetrahydrate, 0.6 part of cerium nitrate hexahydrate and 0.2 part of zirconium oxynitrate dihydrate in 70 parts of ethylene glycol aqueous solution with a volume fraction of 70% and start vigorous stirring at room temperature, and then add to the solution Slowly add 5 parts of silica carrier, continue to stir and raise the temperature to 60 °C for ultrasonic treatment for 4 h, then move it into a vacuum drying oven at 200 °C for 6 h, then put the sample into a tube furnace and pass nitrogen gas at 450 °C °C for 2 h, then switch from nitrogen to air and then roast at this temperature for another 2 h, and finally grind and granulate the sample obtained after roasting to 80-200 mesh. In a fixed bed, the reduction temperature is 550 °C and the volume composition is 45%H 2 / 55%N 2 and space velocity of 3000 mL / (g·h) for 8 h to obtain the methanation nickel-based catalyst. The catalyst composition is: Ni 25 wt%, CeO 2 2.5 wt%, ZrO 2 ...

Embodiment 3

[0034] Dissolve 10 parts of nickel nitrate hexahydrate and 1.6 parts of lanthanum nitrate hexahydrate in 75 parts of 40% glucose aqueous solution by volume and start vigorous stirring at room temperature, then slowly add 5 parts of silica carrier to the solution and continue stirring And heat up to 50 ° C for ultrasonic treatment for 4 h, then move into a vacuum oven to dry at 120 ° C for 4 h, then put the sample into a tube furnace and feed nitrogen at 500 ° C for 2 h, and switch the nitrogen to Air and then roasted at this temperature for 4 h, and finally the samples obtained after roasting were ground and granulated to 80-200 mesh. In a fixed bed, the reduction temperature is 550 °C and the volume composition is 45%H 2 / 55%N 2 and space velocity of 3000 mL / (g·h) for 8 h to obtain the methanation nickel-based catalyst. The catalyst composition is: Ni 26wt%, La 2 o 3 7.8wt%, SiO 2 66.2 wt%.

[0035] The methanation performance of the catalyst was evaluated in a slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com