Drilling clamp

A technology for drilling jigs and drilling templates, which is applied in the direction of clamping, manufacturing tools, and drilling templates for workpieces. Accuracy, large-scale production requirements, low production efficiency and other issues, to achieve the effect of avoiding multi-sequence processing, shortening processing time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

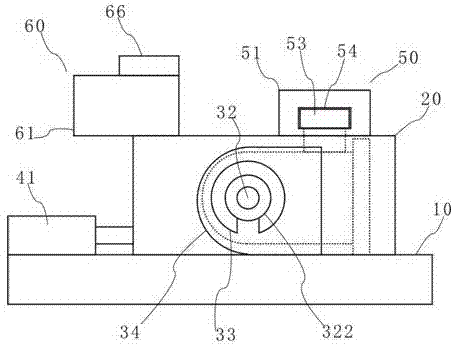

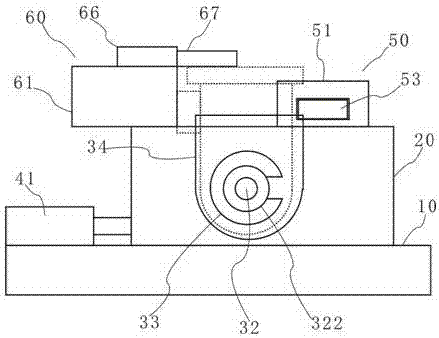

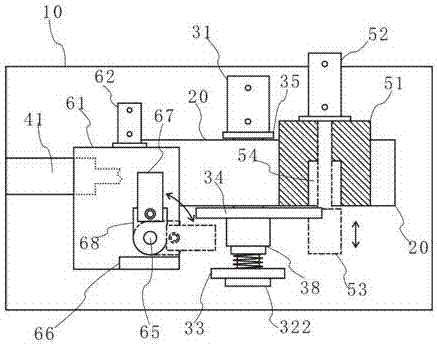

[0027] Such as Figure 1-5 As shown, the present embodiment provides a drilling jig, including a base plate 10 and a positioning seat 20 respectively arranged on the base plate 10, a clamping mechanism, a rotating mechanism, a first drilling module group 50 and a second drilling module group 60, so The clamping mechanism cooperates with the positioning seat 20 to clamp the workpiece to be processed, the rotating mechanism is connected with the clamping mechanism so that the workpiece can be rotated to adjust the processing surface in the clamped state, and the first drilling module 50 The second drilling module 60 is arranged on the other side of the positioning seat 20 and movably cooperates with the second processing surface of the workpiece.

[0028] In this embodiment, the first drilling module group 50 includes a first mold base 51, a telescopic cylinder 52 and a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com