A scr denitrification device

A denitrification and box technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as high temperature, difficult collection and treatment of reaction products, and inability to ensure complete ammonia reaction, so as to achieve easy collection and avoid Multi-processing, easy to collect and process the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

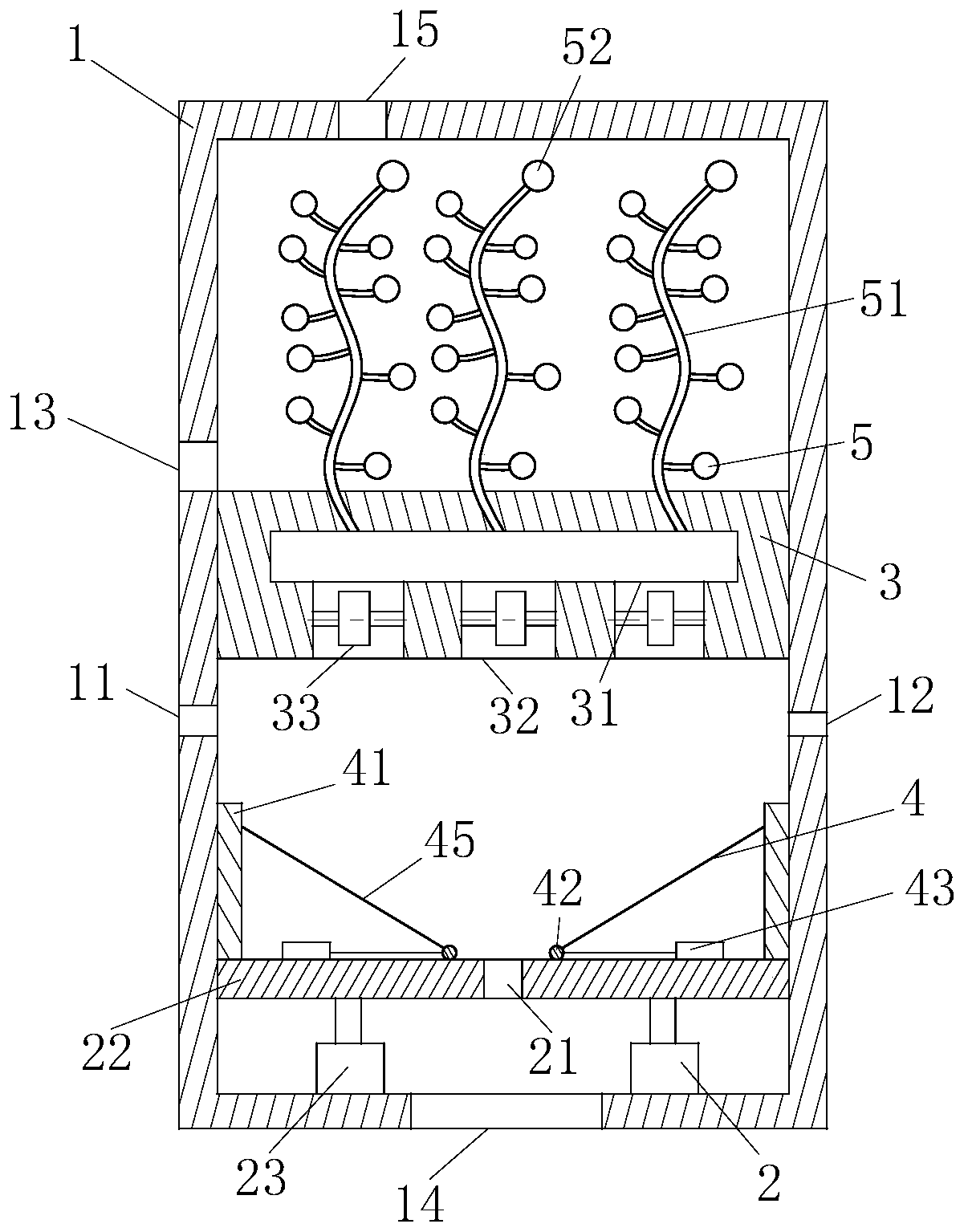

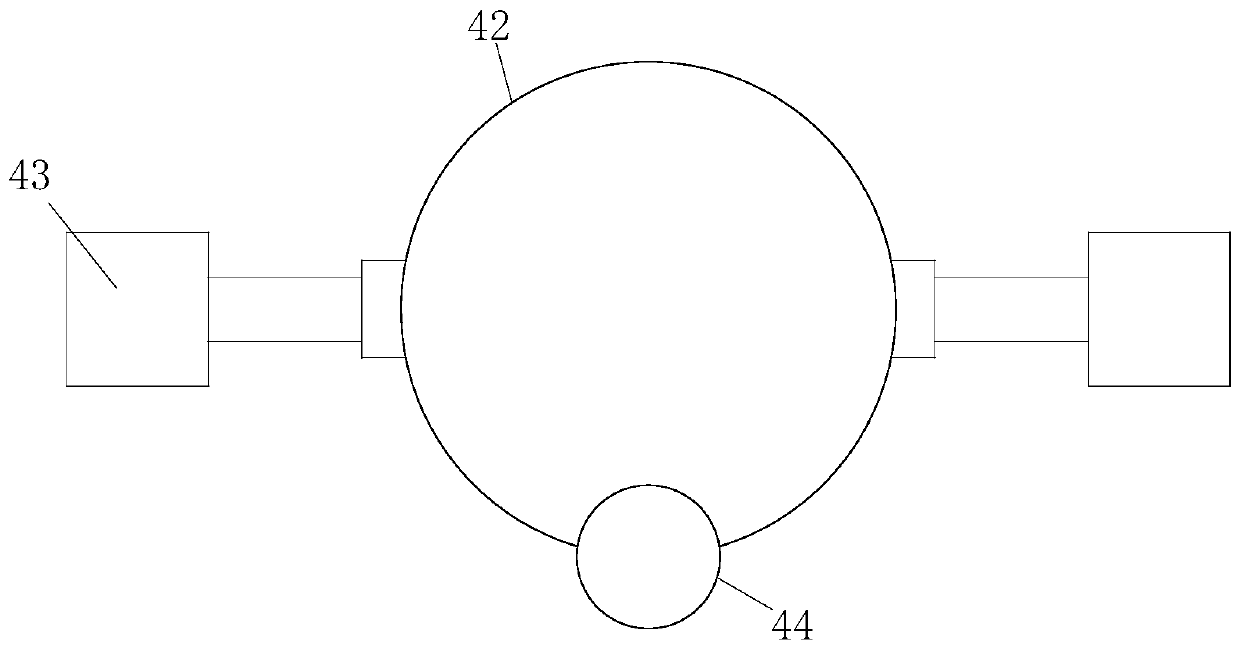

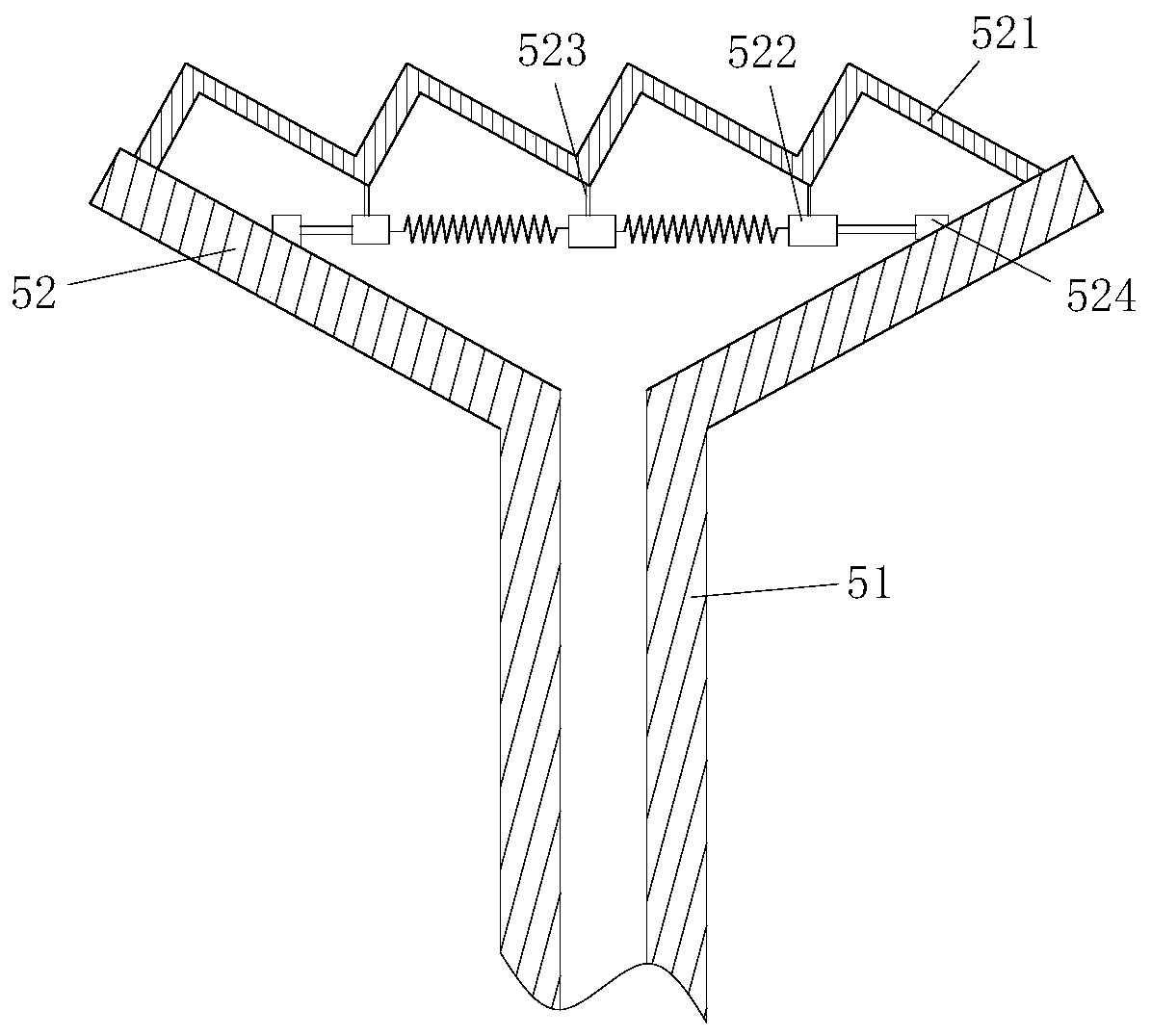

[0021] Such as Figure 1 to Figure 3 As shown, the SCR denitration device according to the present invention includes a box body 1, a push module 2, a fixed plate 3, an adjustment module 4, and a discharge module 5; the push module 2 is located under the box body 1, and the push module 2 It is used to push the reactants in the box 1 into the box 1; the fixed plate 3 is located inside the box 1, and the fixed plate 3 is located above the pushing module 2; the box 1 is provided with an air inlet 11, Ammonia water input port 12, waste liquid discharge port 13, blanking port 14 and gas discharge port 15. The air inlet 11 is located on the left side of the box 1, and the air inlet 11 is located between the push module 2 and the fixed plate 3. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com