Low-helium preform rod wrapping and sintering device and method thereof

A technology of sintering device and preform, which is applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of loss of helium and chlorine gas, influence on wire drawing attenuation, and inability to extract HCl in time, so as to reduce production costs and slow down airflow speed. , the effect of preventing the spread of heat to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

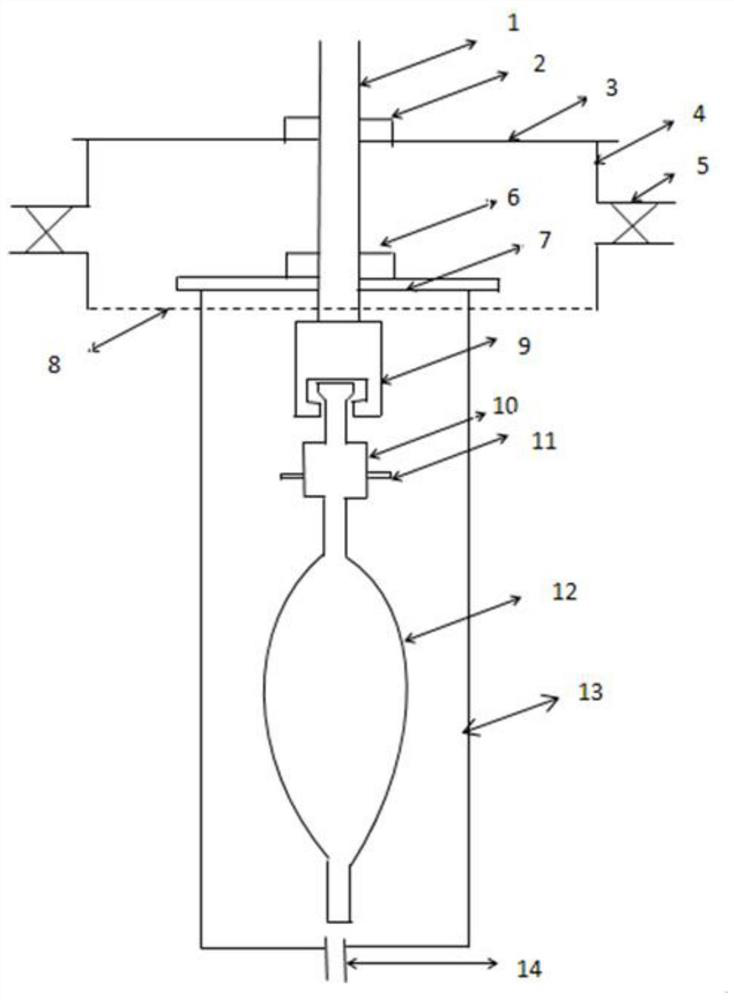

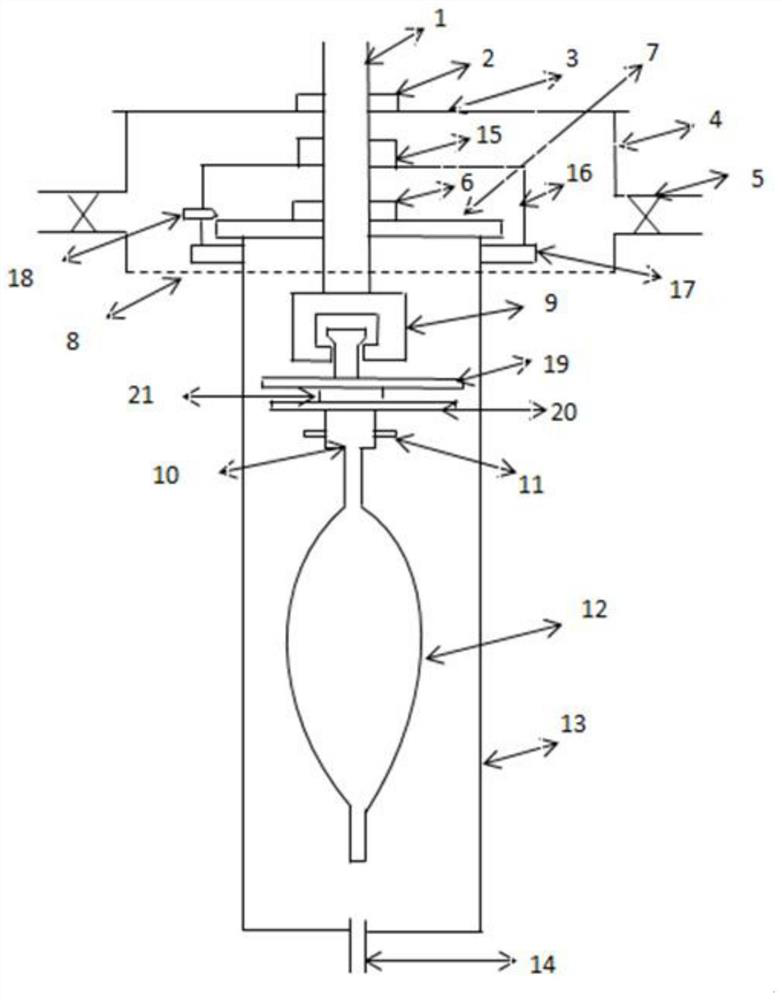

[0029] Such as figure 2 As shown, the present invention provides a low-helium preform outsourcing sintering device, comprising: a furnace core tube 13, the upper end of the furnace core tube 13 is open, and the lower end of the furnace core tube 13 is provided with a gas pipe 14 communicating with the inner cavity of the furnace core tube 13. The mixed gas of gas and chlorine can be poured in the inner cavity of furnace core tube 13 through air pipe 14; One exhaust hood 4, the upper end opening of exhaust hood 4, the bottom end of exhaust hood 4 is sealed and fixed on the pipe body outside of furnace core tube 13, And the upper end opening of the furnace core tube 13 is placed between the inner walls of the exhaust hood 4; it al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com