Multi-stage crucible device used for aluminum nitride single crystal growth

An aluminum nitride, multi-stage technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of unmaintainability, increase the influence of thermal stress, destroy the growing crystal environment, etc., and achieve complete removal, not easy The effect of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

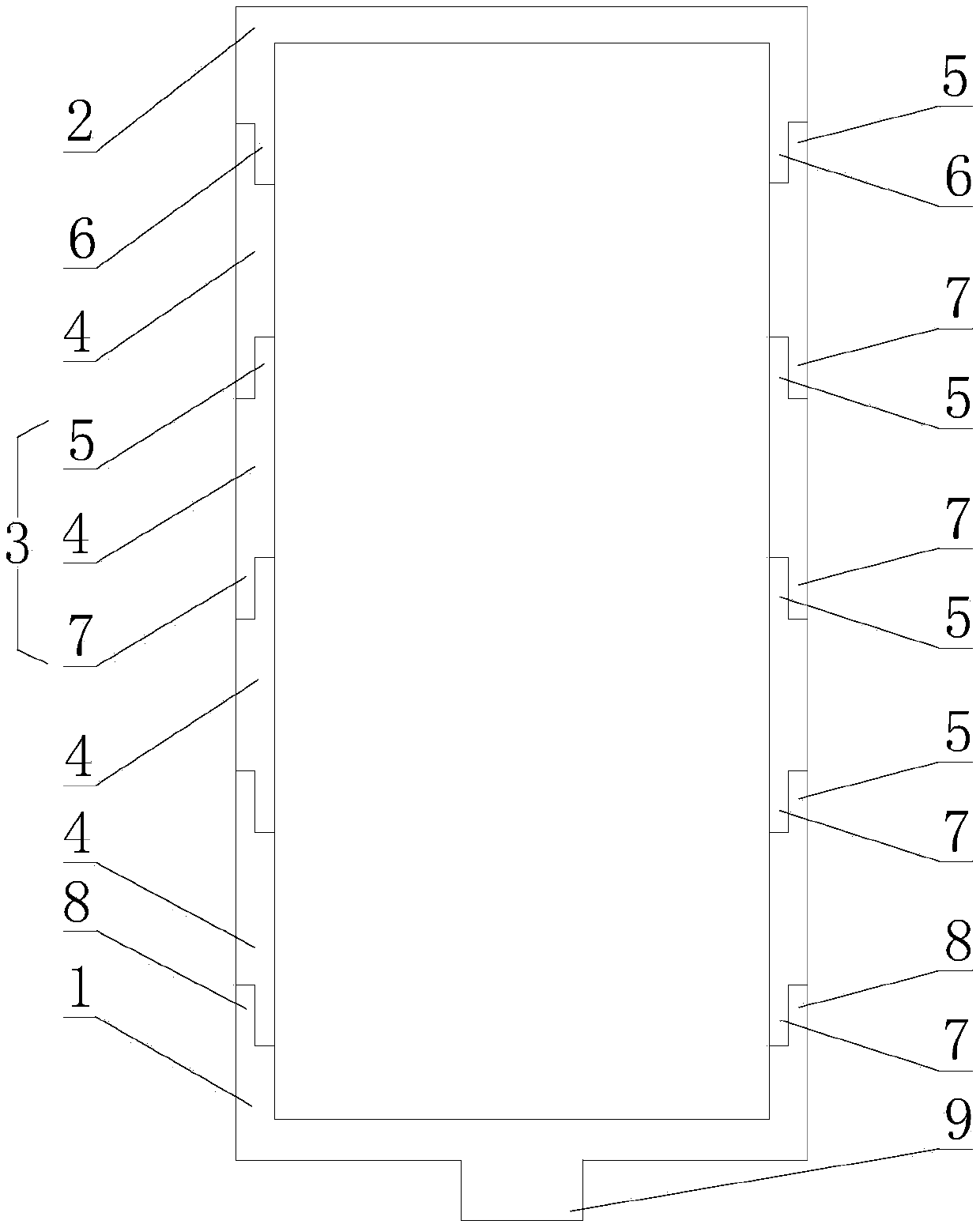

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] see figure 1 As shown, the above-mentioned multi-stage crucible device for aluminum nitride single crystal growth is set on a supporting platform (not shown in the figure).

[0023] The multi-stage crucible device for aluminum nitride single crystal growth includes a crucible body 1 for placing aluminum nitride powder source / aluminum nitride sintered body, a crucible cover 2 covered on the top of the crucible body 1, at least one can The crucible sleeve 3 disposed between the crucible body 1 and the crucible cover 2 is disassembled.

[0024] The aluminum nitride powder source / aluminum nitride sintered body is placed at the bottom of the crucible body 1. Due to the high temperature in the lower part of the crucible, it is not easy to crystallize. By setting the multi-section crucible sleeve 3, after the long-term crystal growth is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com