Pickling roll manufacturing process

A manufacturing process and pickling technology, which is applied in the field of metal material processing, can solve the problems of increasing process control difficulty, energy consumption, and long pickling roll manufacturing process, so as to reduce process complexity and production and processing energy consumption, and improve pickling Processing quality, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

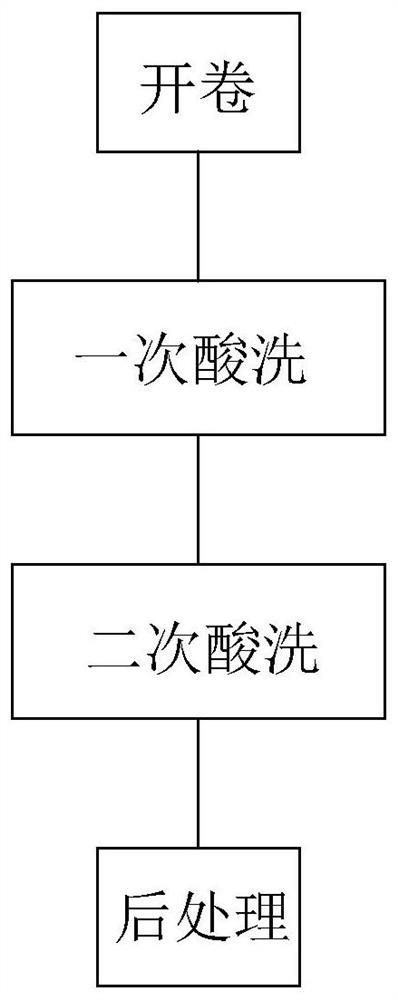

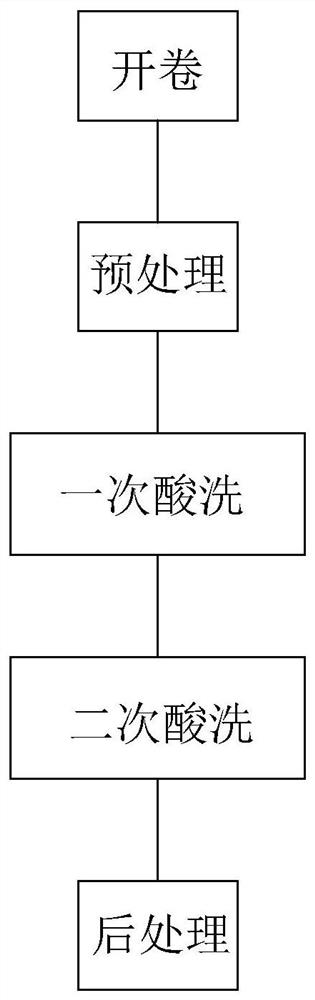

[0055] A kind of pickling roll manufacturing process, its technological process is as figure 1 As shown, specifically include the following steps,

[0056] Uncoiling: Uncoil the hot-rolled steel coil through uncoiling equipment, and then straighten it to obtain straightened strip steel.

[0057] One-time pickling: pickling the pretreated straightened steel strip with pickling solution at 30°C, after pickling for 10 minutes, wash off the residual pickling solution with clean water.

[0058] Second pickling: pickling the pretreated straightened steel strip with pickling solution at 30°C, after pickling for 10 minutes, wash off the residual pickling solution with water; repeat the washing three times, the cleaning water temperature is 50°C , wash 10min each time.

[0059] Post-treatment: After drying the surface moisture of the straightened steel strip that has undergone first pickling and second pickling with hot air, spray anti-rust oil evenly on the surface of the straighten...

Embodiment 2

[0073] A kind of pickling roll manufacturing process, its technological process is as figure 1 As shown, specifically include the following steps,

[0074] Uncoiling: Uncoil the hot-rolled steel coil through uncoiling equipment, and then straighten it to obtain straightened strip steel.

[0075] One-time pickling: Pickling the pretreated straightened steel strip with pickling solution at 40°C, after pickling for 8 minutes, wash off the residual pickling solution with clean water.

[0076] Second pickling: pickling the pretreated straightened steel strip with pickling solution at 35°C, after pickling for 8 minutes, wash off the residual pickling solution with water; repeat the washing three times, the cleaning water temperature is 40°C , wash 12min each time.

[0077] Post-treatment: After drying the surface moisture of the straightened steel strip that has undergone first pickling and second pickling with hot air, spray anti-rust oil evenly on the surface of the straightened...

Embodiment 3

[0091] A kind of pickling roll manufacturing process, its technological process is as figure 1 As shown, specifically include the following steps,

[0092] Uncoiling: Uncoil the hot-rolled steel coil through uncoiling equipment, and then straighten it to obtain straightened strip steel.

[0093] One-time pickling: Pickling the pretreated straightened steel strip with pickling solution at 40°C, after pickling for 8 minutes, wash off the residual pickling solution with clean water.

[0094] Second pickling: pickling the pretreated straightened steel strip with pickling solution at 40°C, after pickling for 7 minutes, wash off the residual pickling solution with water; repeat the washing three times, the washing water temperature is 35°C , wash 13min each time.

[0095] Post-treatment: After drying the surface moisture of the straightened steel strip that has undergone first pickling and second pickling with hot air, spray anti-rust oil evenly on the surface of the straightened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com