Integrated type electronic hydraulic braking system and method

A hydraulic braking, integrated technology, applied in the direction of brakes, brake transmission devices, braking action starting devices, etc., can solve the problems of restricting the promotion of electronic hydraulic braking system products, large size of brakes, low integration, etc. Easy replacement and maintenance, smooth pedal feel, highly integrated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

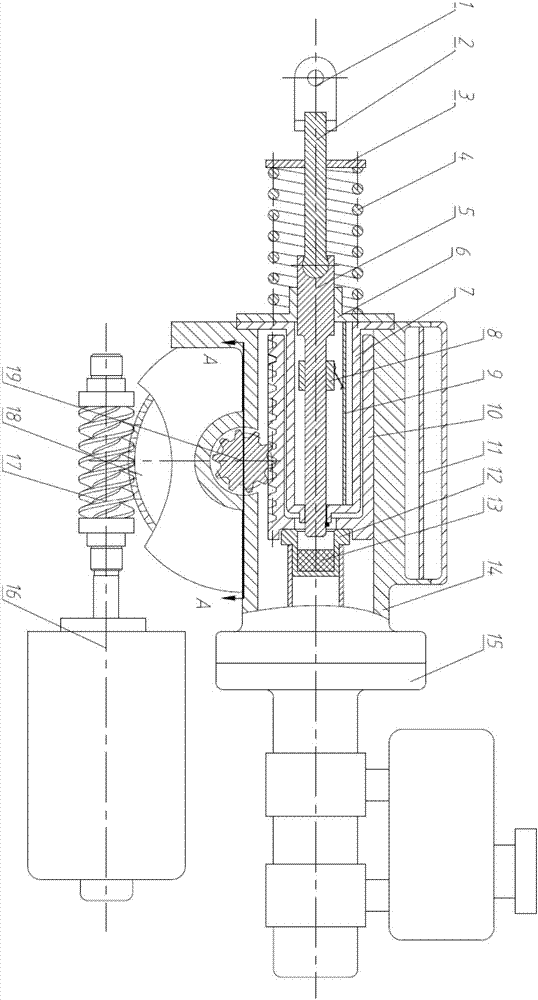

[0040] like figure 1 As shown, an integrated electro-hydraulic braking system includes: a motor 16 and a worm gear and rack two-stage reduction mechanism to provide the pressure building force of the master cylinder 15; a pedal feeling simulation device, which simulates the elastic element 4 and the elastic The component base 3 is used to simulate the pedal feeling of traditional braking; the pedal displacement sensor is composed of a sensor slider 8 installed on the master cylinder push rod 5, an induction device and a sensor housing 7 arranged inside the rack 10, It is used to collect pedal displacement information; the decoupling structure realizes decoupling through the gap left between the master cylinder push rod 5 and the master cylinder joint 12 to meet the functional requirements of regenerative braking; the failure backup structure consists of the pedal push rod 2, Master cylinder push rod 5, buffer block 15, master cylinder joint 12, can provide part of the brake pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com