Pickup device and blister packaging machine

A pick-up device and pick-up position technology, applied in the directions of transportation and packaging, packaging, packaging protection, etc., can solve the problems of item damage, unable to fully ensure the safety and reliability of recovered items, etc., to reduce costs and improve convenience. Sex, the effect of suppressing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] One embodiment will be described below with reference to the drawings.

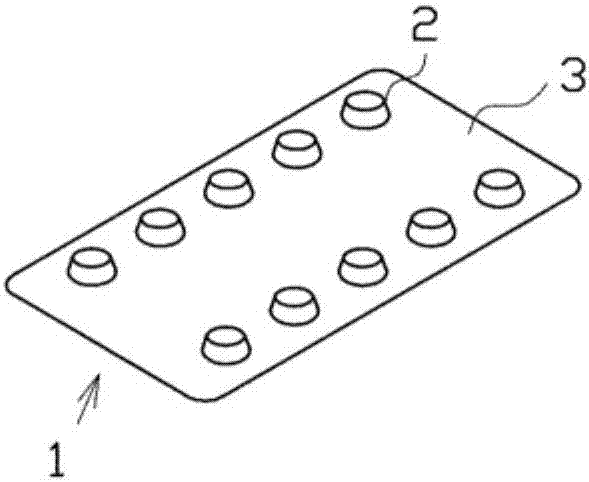

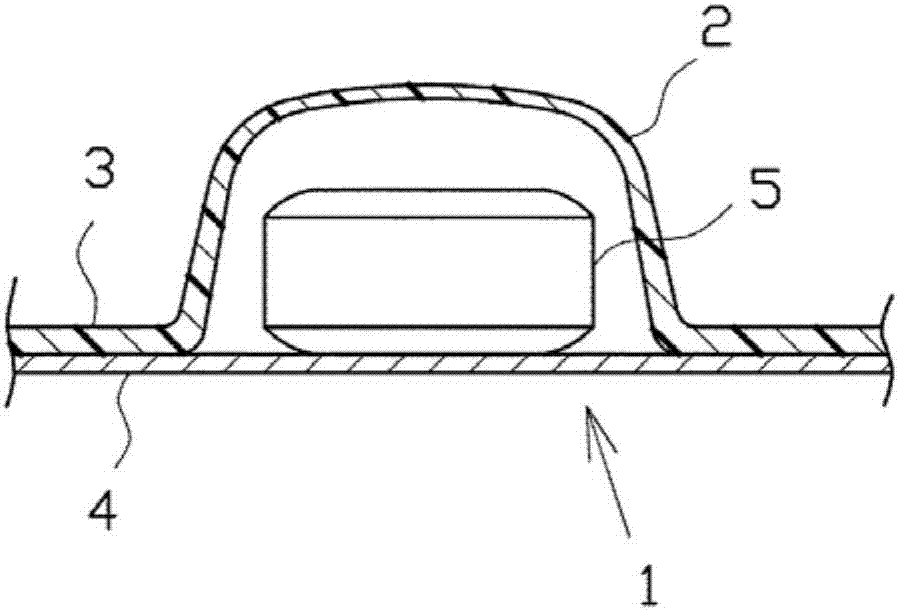

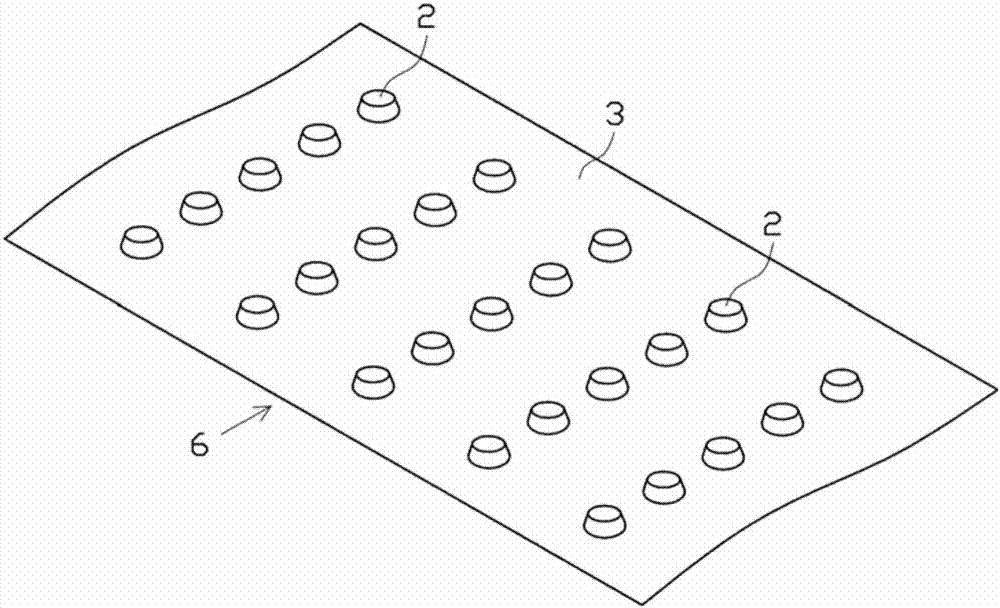

[0099] First, the PTP sheet 1 as a blister sheet will be described. picture figure 1 and figure 2 As shown, the PTP sheet 1 includes a container film 3 having a plurality of pockets 2 ; and an overcoat film 4 covering the container film 3 so as to close the pockets 2 .

[0100] The container film 3 is formed of a thermoplastic resin material such as PP (polyethylene), PVC (polyvinyl chloride), aluminum foil, or the like.

[0101] On the other hand, the cover film 4 is made of an opaque material (for example, aluminum foil, etc.), and a sealant made of polyester resin or the like is coated on the surface thereof.

[0102] The PTP sheet 1 has a substantially rectangular shape when viewed from a planar view, and pocket rows consisting of five pocket portions 2 arranged in the longitudinal direction of the sheet are formed in two rows in the sheet width direction. That is, a total of 10 pockets 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com