Screw ship unloader provided with vertical telescopic pneumatic material taking head

A technology of vertical screw and ship unloader, applied in the direction of conveyor, loading/unloading, conveying bulk materials, etc. It can solve the problems of rigid collision between the screw reclaiming head and the bottom of the ship, hidden dangers of safety accidents, and low clearance efficiency, etc., to achieve a wide range Market application prospects, good environmental performance, and high clearance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

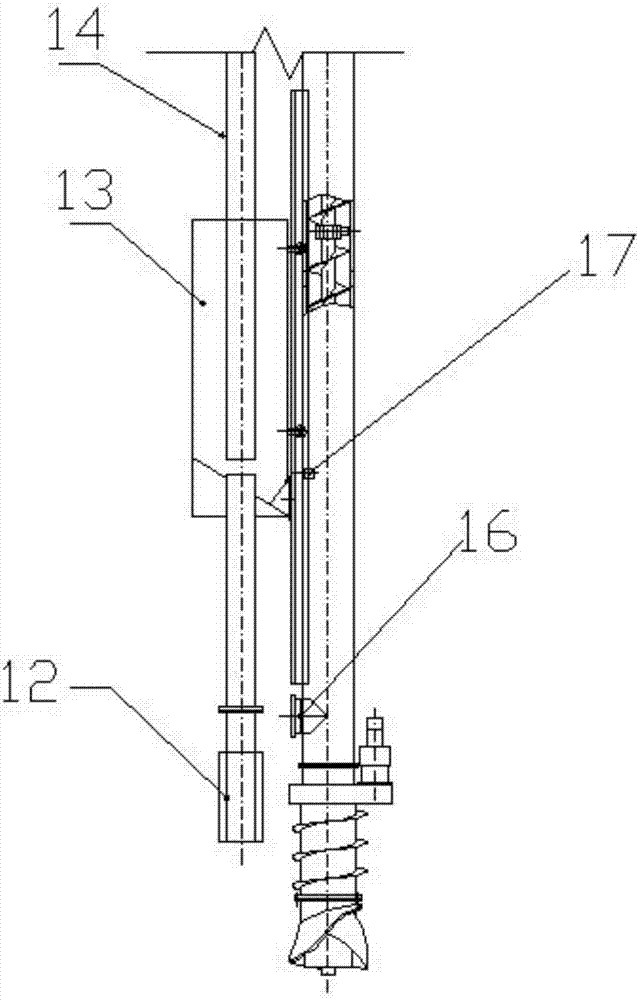

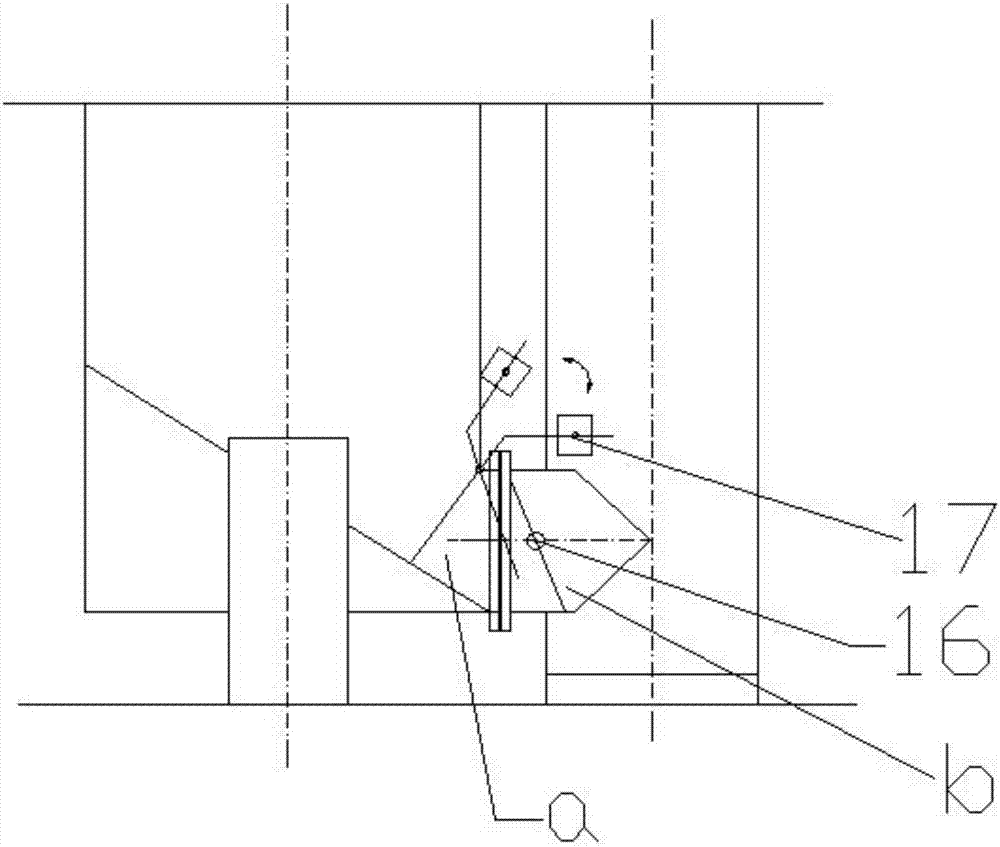

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: it includes a screw pick-up head 1, a vertical screw conveyor 2, a horizontal screw conveyor 3, a frame 4, a slewing mechanism 5, a pitch cylinder 6, a swing cylinder 7, a horizontal containment Dust pipe 8, dust collector 9, negative pressure air source system 10, clean air pipe 11, pneumatic feeding head 12, material settling chamber 13, vertical dust-containing air pipe 14, vertical lifting guide rail 15, pneumatic butterfly valve 16, gravity valve 17 and the bulk carrier 18, the lower end of the vertical screw conveyor 2 is connected with a screw picker 1, the upper end of the vertical screw conveyor 2 is connected with a horizontal screw conveyor 3 in the horizontal direction, and the vertical screw conveyor 2 is vertically A vertical lifting guide rail 15 is installed in the direction, and a material settling chamber 13 is slidably connected to the vertical lifting gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com