Method for preparing fragrant film by using essence microcapsule

A fragrance microcapsule and microcapsule technology, which is applied in the preparation of fragrance film, using essence microcapsule to prepare fragrance film field, can solve the problems such as no fragrance microcapsule film, and achieve the effect of facilitating development and utilization and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

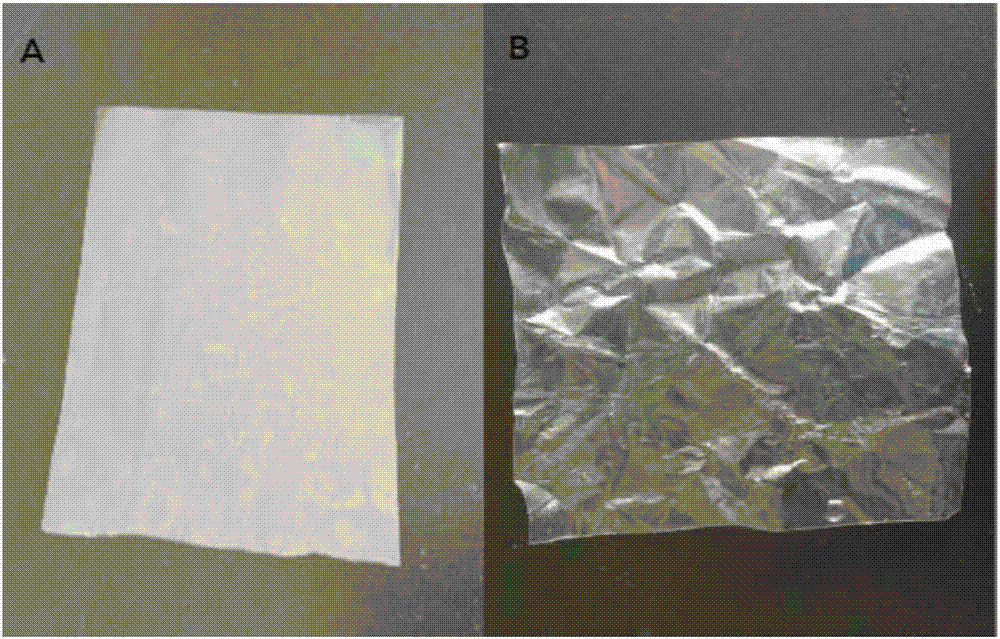

[0020] 1) Add 1g of flavor microcapsule powder with milk aroma into 99ml of distilled water to prepare a flavor microcapsule solution with a volume fraction of 1%, and stir with a glass rod to fully dissolve the microcapsules to obtain a microcapsule solution;

[0021] 2) Preheat the microcapsule solution obtained in step 1) to 75°C, put it into a polypropylene film with a size of 10*10cm, seal it with a plastic wrap, put it in an oven at 80°C for heating, take it out after heating for 1 hour, and wash it with water surface residues to obtain a fragrance microcapsule film (a).

Embodiment 2

[0023] 1) Add 0.1g of essence microcapsule powder with milk aroma into 99.9ml of distilled water to prepare a fragrance microcapsule solution with a volume fraction of 0.1%, and stir with a glass rod to fully dissolve the microcapsules to obtain a microcapsule solution;

[0024] 2) Preheat the microcapsule solution obtained in step 1) to 75°C, put it into a polypropylene film with a size of 10*10cm, seal it with a plastic wrap, put it in an oven at 80°C for heating, take it out after heating for 0.5 h, and wash it with water surface residues to obtain fragrance microcapsule film (b).

Embodiment 3

[0026] 1) Add 3g of flavor microcapsule powder with milk aroma into 97ml of distilled water to prepare a flavor microcapsule solution with a volume fraction of 3%, and stir with a glass rod to fully dissolve the microcapsules to obtain a microcapsule solution;

[0027] 2) Preheat the microcapsule solution obtained in step 1) to 85°C, put it into a polypropylene film with a size of 10*10cm, seal it with a plastic wrap, put it in an oven at 70°C for heating, take it out after heating for 2 hours, and wash it with water surface residues to obtain a fragrance microcapsule film (c).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com