Environment-friendly fluoride-free waterproofing agent as well as preparation method and application thereof

A fluorine-free water repellent, an environmentally friendly technology, applied in antifouling/underwater coatings, fireproof coatings, transportation and packaging, etc., can solve the problems of narrow application areas, achieve low cost, wide and rich raw material sources, and hot water resistance The effect of outstanding permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of environment-friendly fluorine-free waterproofing agent:

[0043] Put polymethylhydrogensiloxane, sodium dodecylbenzenesulfonate as emulsifier, tetradecyl acrylate as thickener (mass ratio 8:1:1) in a beaker, stir and dissolve at 45°C, Add an equal volume of deionized water preheated to 45°C, and stir at a high speed under ultrasonic waves to obtain a methyl hydrogen-containing siloxane emulsion;

[0044] Put diphenylsilanediol, sodium dodecylbenzenesulfonate as emulsifier, tetradecyl acrylate as thickener (mass ratio 8:1:1) in a beaker, stir and dissolve at 45°C, add An equal volume of deionized water preheated to 45°C was stirred at high speed under ultrasonic waves to obtain a hydroxysilane emulsion;

[0045] Put carboxypolyethylene glycol silane, sodium dodecylbenzenesulfonate as emulsifier, tetradecyl acrylate as thickener (mass ratio 8:1:1) in a beaker, stir and dissolve at 45°C, add An equal volume of deionized water preheated to 45°C was stirred ...

Embodiment 2

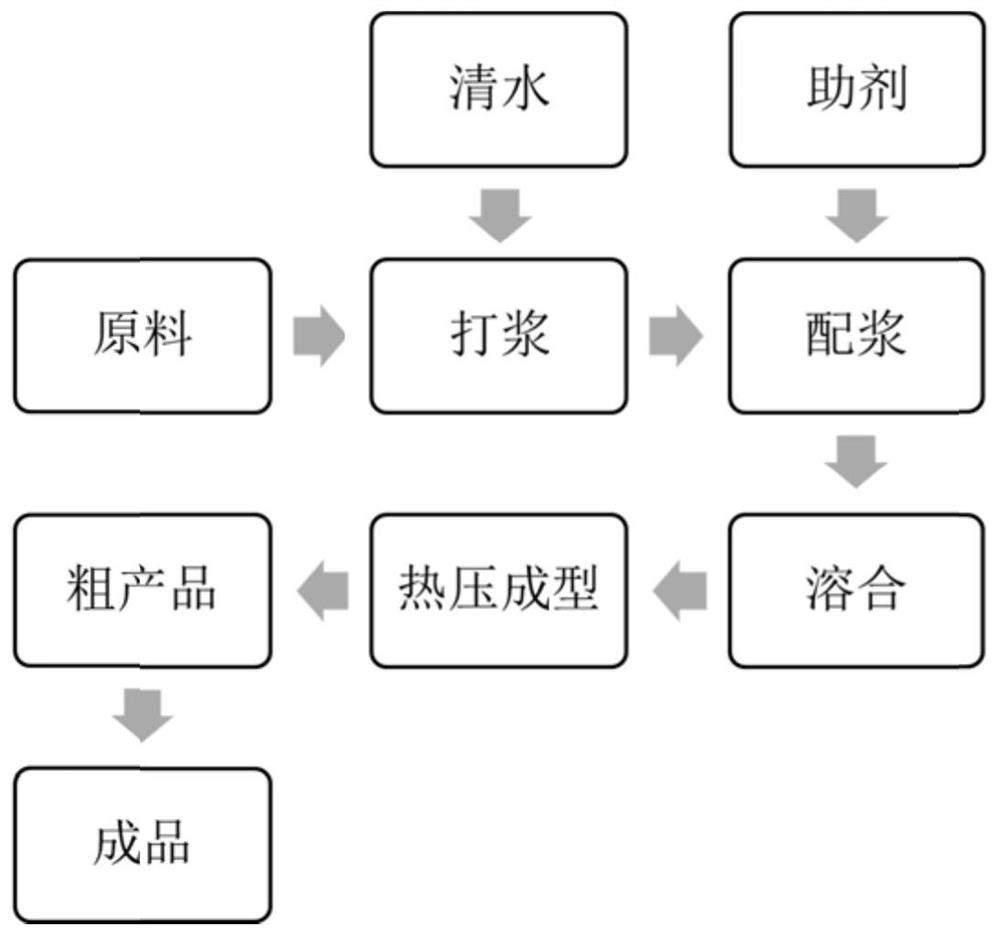

[0048] The preparation of plant fiber degradable and environmentally friendly packaging lunch boxes can use the existing preparation methods of conventional plant cellulose degradable lunch boxes, or refer to the following preparation process: dry the agricultural straw and bagasse raw materials, and sieve them out after drying. The sand and heavy impurities mixed in the raw materials are crushed into pieces and mixed evenly at a mass ratio of 9:1 to facilitate pulping. The crushed raw materials are steamed in hot water (100°C for half an hour), squeezed and put into the pulp tank. Add a large amount of clean water, the mass ratio of water to material is about 25:1, add 16% sodium hydroxide aqueous solution, the total amount added is one-fifth of the water volume, and add anthraquinone reagent, which helps to improve cooking efficiency Its mass is 0.1% of water. After boiling, continue cooking and stirring for 3 hours to dissolve the plant cellulose in the raw material, separat...

Embodiment 3

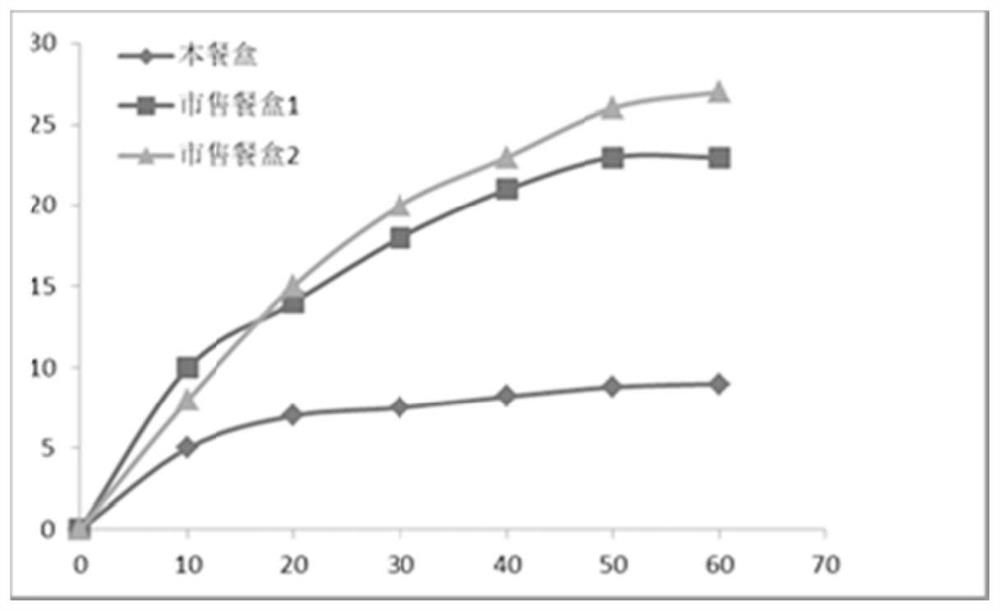

[0050] Degradation performance test of the prepared plant fiber degradable environmental protection packaging lunch box

[0051] The biodegradability of the lunch box prepared in Example 2 was tested and analyzed according to the composting results of the outdoor field. Firstly, the lunch box is buried in the organic soil obtained by mixed biodegradation (the compost is obtained from the compost produced by organic matter in municipal solid waste), and the biodegradation test is carried out on the lunch box. The compost decomposition method characterizes the biodegradability index of the lunch box, such as Table 1, including mass loss rate, biodegradation rate and CO 2 amount released. Table 1 shows that the plant fiber degradable environmental protection packaging lunch box in the present invention has good biodegradability and will not cause pollution pressure to the ecological environment after use.

[0052] Table 1 Degradation performance index of plant fiber degradable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com