A kind of beneficiation method for comprehensive utilization of high-iron aluminum ore

A technology for high-iron bauxite and mineral processing methods, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of inappropriate equipment selection, failure to develop and utilize, and high operating costs, and achieve simple and effective equipment. Fast and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

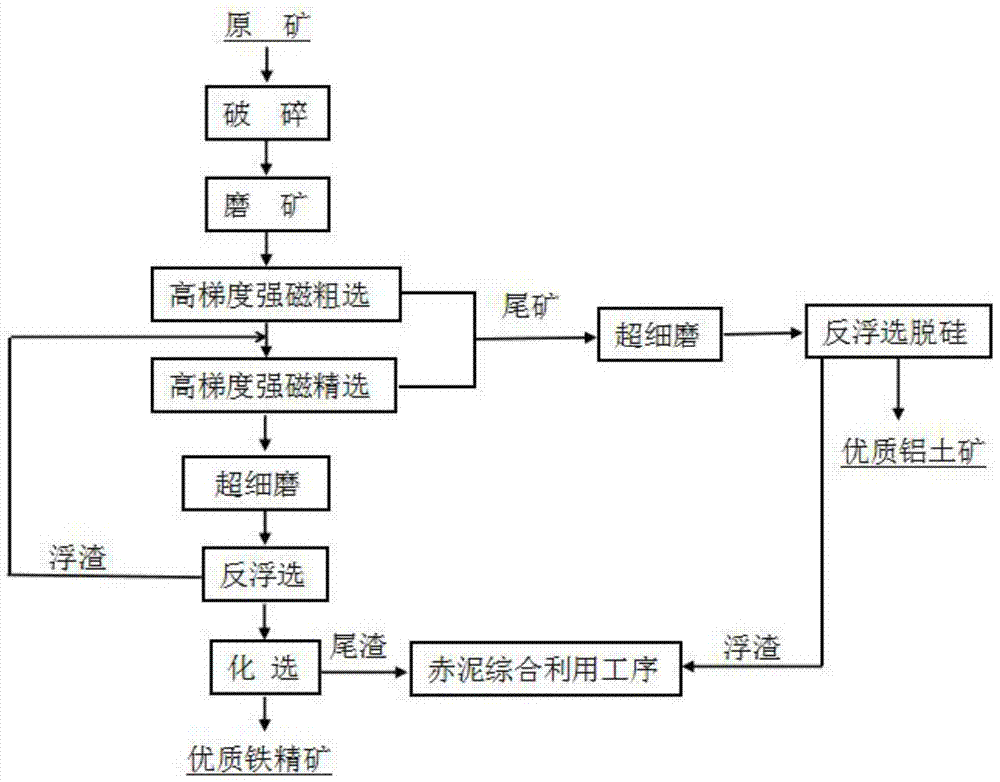

[0028] The beneficiation method of high-iron bauxite comprehensive utilization of the present invention comprises the following steps:

[0029] 1.1 Preprocessing

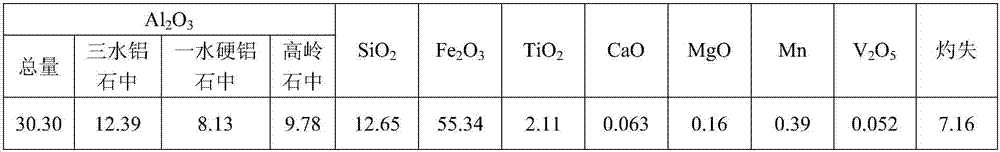

[0030] The high-iron bauxite ore is crushed first, and the ore is ground to a particle size of 38 μm to 75 μm, and then sent to the thickener, and the underflow pump is sent to the pulping tank for pulping, and the pulp concentration is adjusted to 30 to 50%, and the iron content is 12 to 45%. The aluminum content is 10-45%, the average temperature is normal temperature, and the supernatant is returned to the ore flushing or pulping.

[0031] 1.2 Particle size screening

[0032] After pulping, the pulp is sent to the cylindrical sieve for sieving, and the sieve residue with a particle size greater than 500 μm is returned to the grinding process, and the pulp with a particle size of less than 500 μm enters the next process—high gradient magnetic separator. At this stage, all unloading water enters the tailings , Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com