Single-cylinder compressor provided with oil-feed pump

A technology for compressors and oil inlet pumps, which is applied to pump components, mechanical equipment, variable capacity pump components, etc. It can solve the problems of severe heat generation in the cylinder block, unsatisfactory heat dissipation effect, and low oil temperature, so as to achieve sustainable improvement The ability to work, improve the heat dissipation effect, and the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

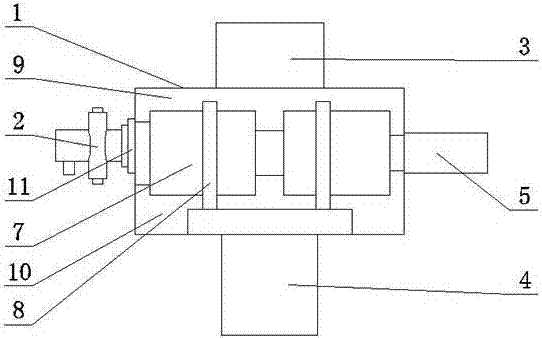

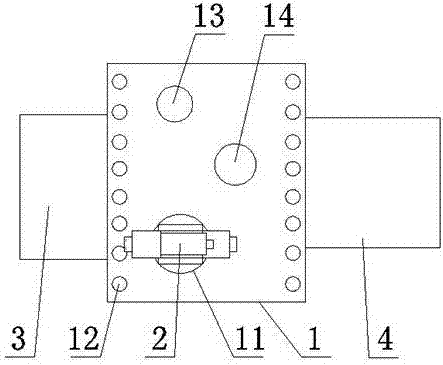

[0016] Such as figure 1 and figure 2 As shown, a single-cylinder compressor with an oil inlet pump includes a single-cylinder compressor 1 and a circulating oil inlet pump 2. An air inlet cylinder 4 is arranged on the front surface of the single cylinder compressor 1, and an air outlet cylinder 3 is arranged on the rear surface. The right surface is provided with an external input shaft 5, the left surface is provided with a shaft hole plate 11, and the inner surface of the left surface of the single-cylinder compressor 1 is provided with an internal compressor 7, and the internal compressor 7 is set on the external input shaft 5. , the inner surface of the front surface of the single-cylinder compressor 1 is provided with a crank compressor 8, the crank compressor 8 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com