Load self-adaption type stroke dependent variable-damping shock absorber

An adaptive, shock absorber technology, applied in the direction of shock absorber, shock absorber-spring combination, spring/shock absorber functional characteristics, etc. and other problems, to achieve the effect of compact structure, good vibration reduction effect and sensitive response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in detail below in conjunction with accompanying drawing:

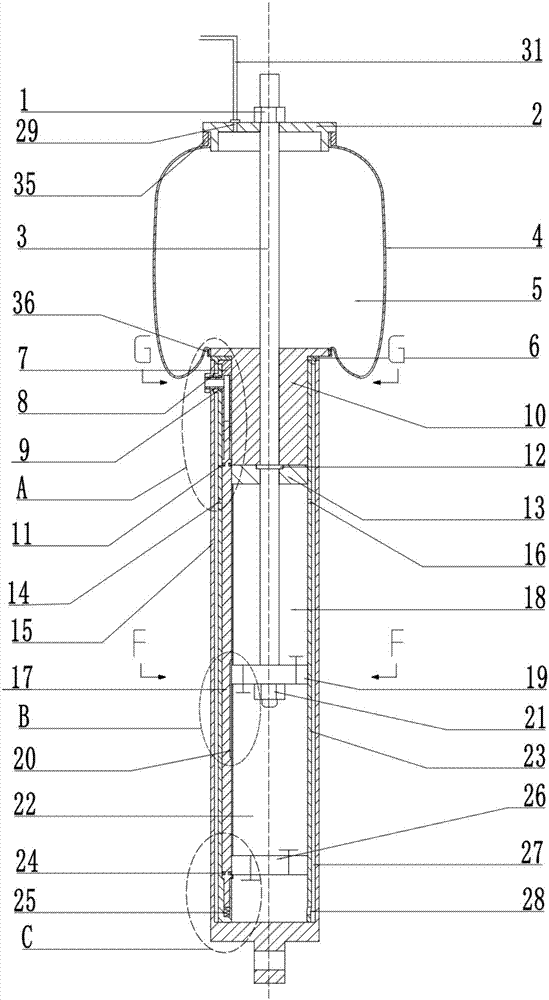

[0047] refer to figure 1 , the load adaptive stroke-related variable damping shock absorber described in the present invention includes a shock absorber, an air spring 4 (or a coil spring 32), a pneumatic adjustment device and a pneumatic actuator; wherein:

[0048] The shock absorber is a two-tube structure, and the shock absorber includes an upper nut 1, an upper top cover 2, a piston rod 3, a sealing plate 6, a top cover 10, a No. 4 sealing ring 12, a limit block 13, an outer Cylinder 15, piston assembly 19, nut 21, inner cylinder 23, bottom valve assembly 26, No. 1 sealing pressure ring 35 and No. 2 sealing pressure ring 36.

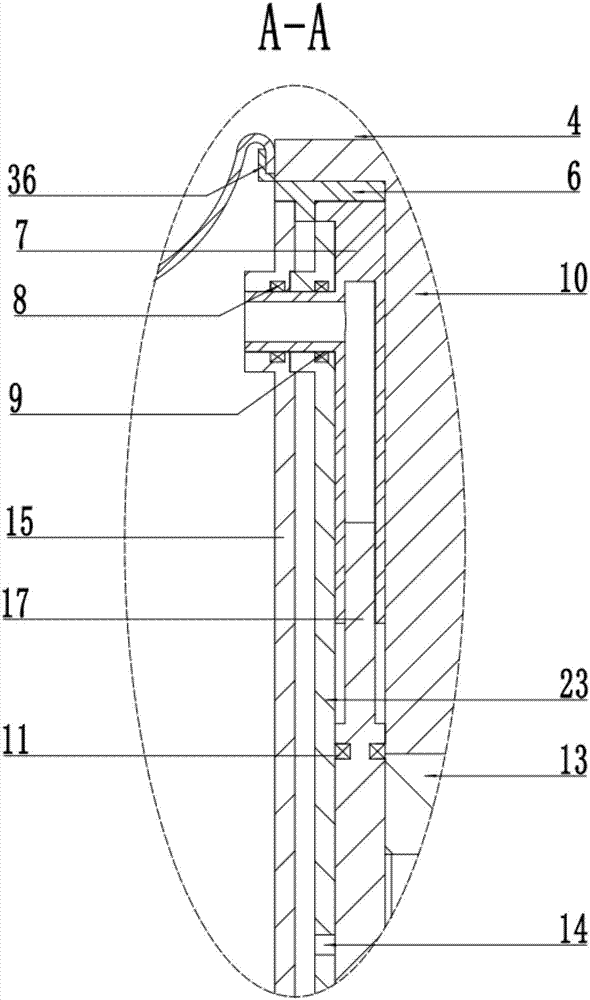

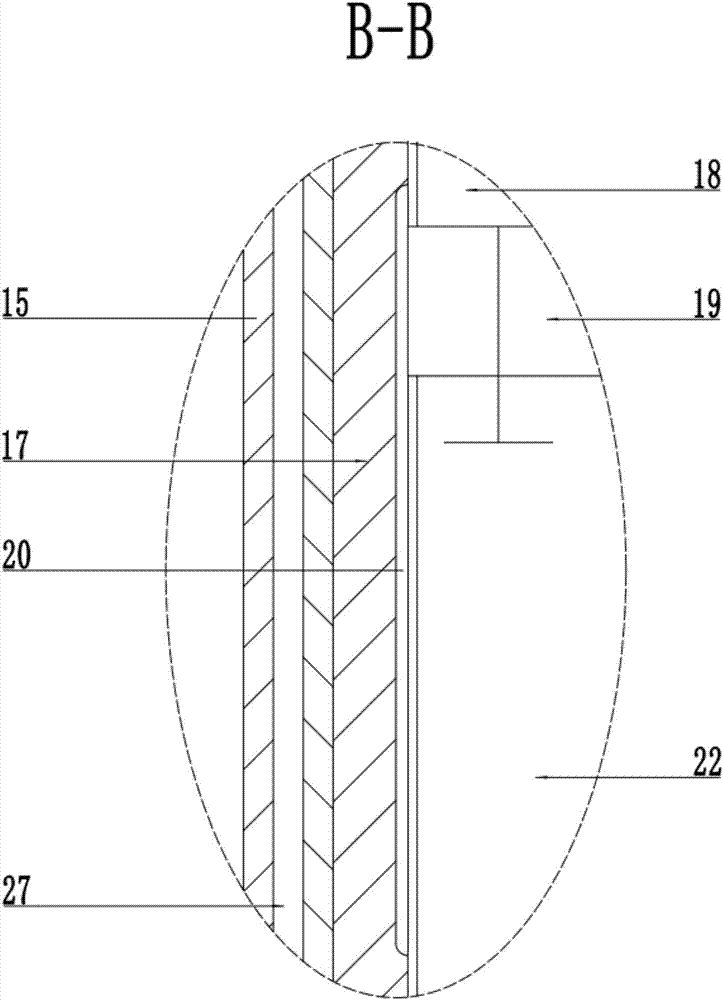

[0049] refer to figure 1 , Figure 1-a , Figure 1-c , Figure 1-h and Figure 1-i , the inner cylinder 23 is a cylindrical structure with upper and lower ends open, consisting of a main cylinder and a small torus with a central angle of less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com