Wire diameter measurement special tool

A special tool and wire diameter technology, applied in the field of special tools for wire diameter measurement, to achieve the effects of easy portability, accurate data measurement, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

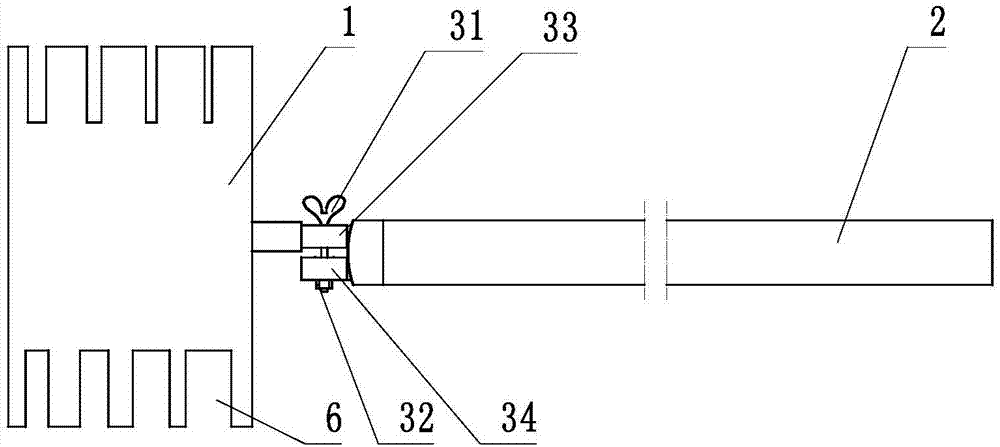

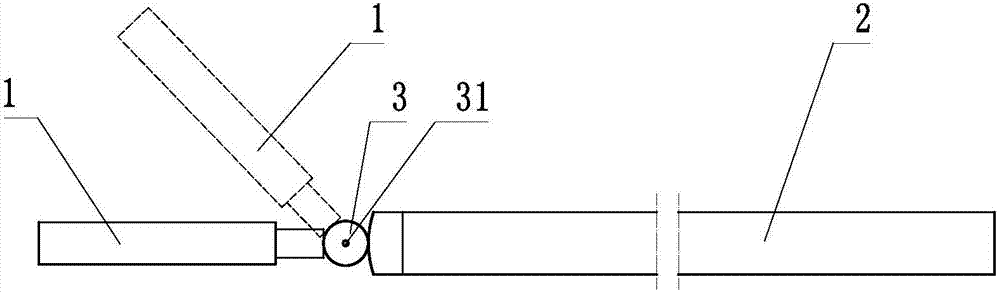

[0031] Embodiment 1: refer to Figure 1~2 , which is a structural schematic diagram of this embodiment, a special tool for measuring wire diameters, including a measuring board 1 and an insulating rod 2, the measuring board 1 is a plate-shaped structure and 2 to 10 measuring devices of different specifications are arranged at the edge Port 6, the measuring port 6 is a notch arranged on the edge of the measuring plate 1, the notch is in a "U" shape, that is, the opposite sides are parallel to each other, and the distance between the two opposite parallel sides of each measuring port 6 is different, One end of the insulating rod 2 is a free end, and the other end is connected with the measuring plate 1 through the adjusting mechanism 3, the measuring plate 1 and the adjusting mechanism 3 are welded, the insulating rod 2 is riveted with the adjusting mechanism 3, and the measuring The plate 1 and the insulating rod 2 can rotate relatively around the adjusting mechanism 3, the adj...

Embodiment 2

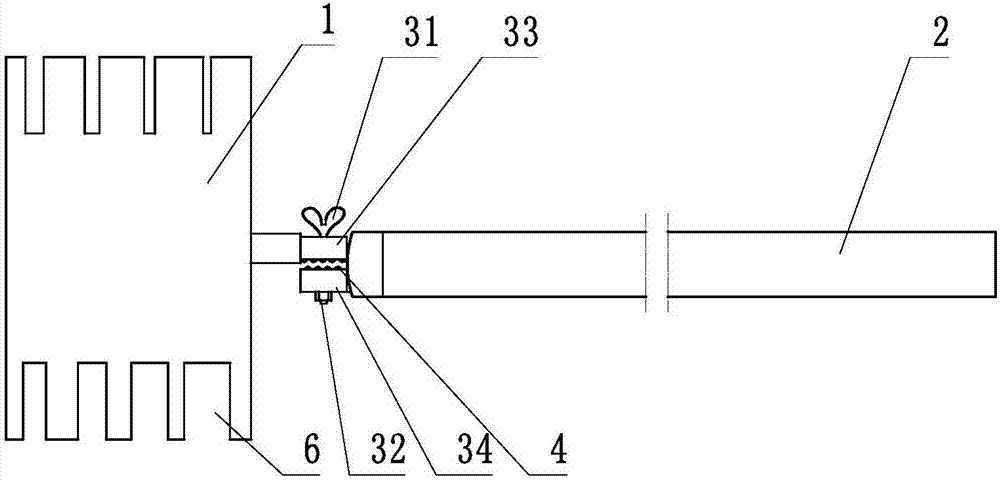

[0033] Embodiment 2: refer to image 3 , is a schematic diagram of the structure of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the contact surfaces of the fastener A33 and the fastener B34 are provided with multiple sets of anti-skid protrusions that engage with each other 4, and the anti-slip protrusion 4 is arranged at the edge of the contact surface of the fastener A33 and the fastener B34, the anti-slip protrusion 4 is a cone structure, and the above-mentioned anti-slip protrusion 4 can prevent the fastener A33 and The relative movement of the part B34 ensures that the relative position of the measuring board 1 and the insulating rod 2 remains unchanged during the operation.

Embodiment 3

[0034] Embodiment 3: refer to Figure 4~5 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with any embodiment of Embodiments 1 to 2, the difference of this embodiment is that the insulating rod 2 can be stretched, and the specific structure is as follows: the insulating rod 2 includes mutually plugged The outer sleeve 21 and the inner sleeve 22, the outer sleeve 21 is provided with a plurality of limiting holes 52, the inner sleeve 22 is provided with a groove 54, and the groove 54 is provided with a limiting block 51 and a spring 53, When the length of the insulating rod 2 needs to be fixed, the limit block 51 is passed through the limit hole 52 and clamped. When it needs to be extended or shortened, the limit block 51 is pressed into the groove 54, and the outer sleeve 21 and the inner sleeve are relatively moved. After the pipe 22 is fixed, the stop block 51 is ejected from the groove 54 under the action of the spring, and continues to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com