Weighing module

A weighing module and sensor technology, applied in the direction of weighing, detailed information of weighing equipment, instruments, etc., can solve the problem of reduced work reliability, damage to weighing modules and connectors, no horizontal protection device and anti-dumping mechanism, etc. problem, to achieve the effect of tight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

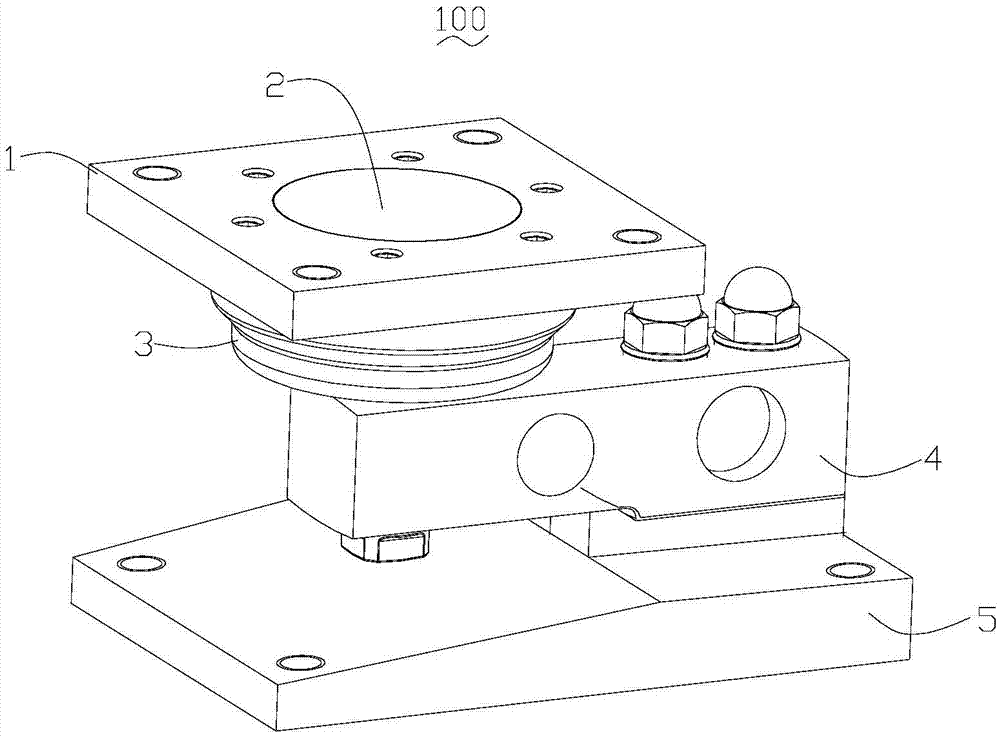

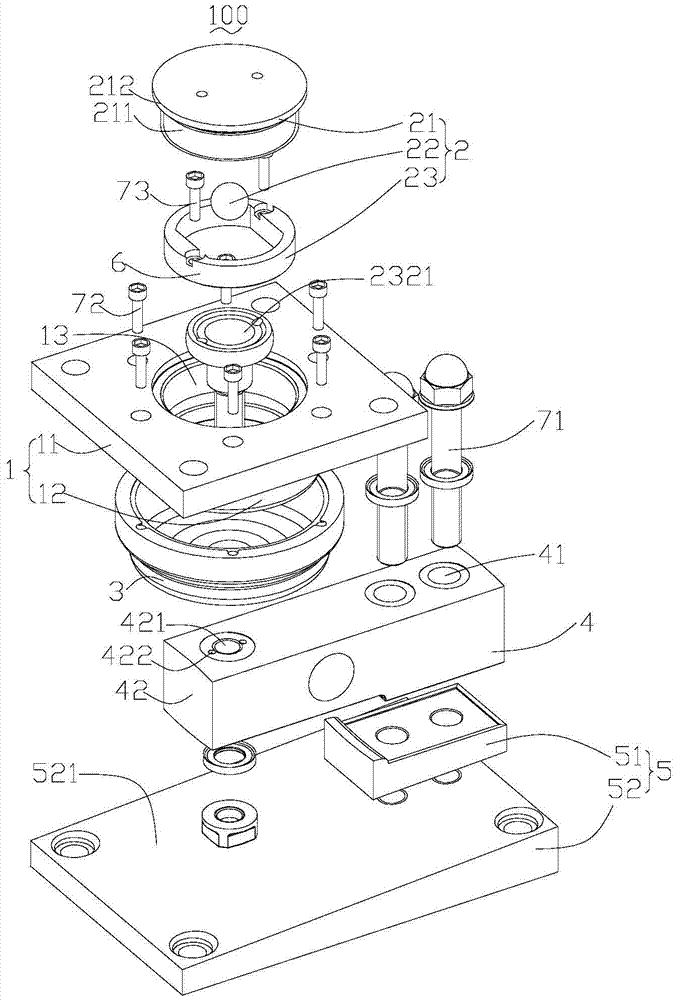

[0025] see Figure 1 to Figure 2 As shown, the present invention is a weighing module 100, which includes a sensor 4, a carrier frame 1 arranged above the sensor 4 for mounting an object to be carried, a force transmission member 2, a fixing seat 5 arranged below the sensor 4, a sealing Part 3, guide 6 and some screws.

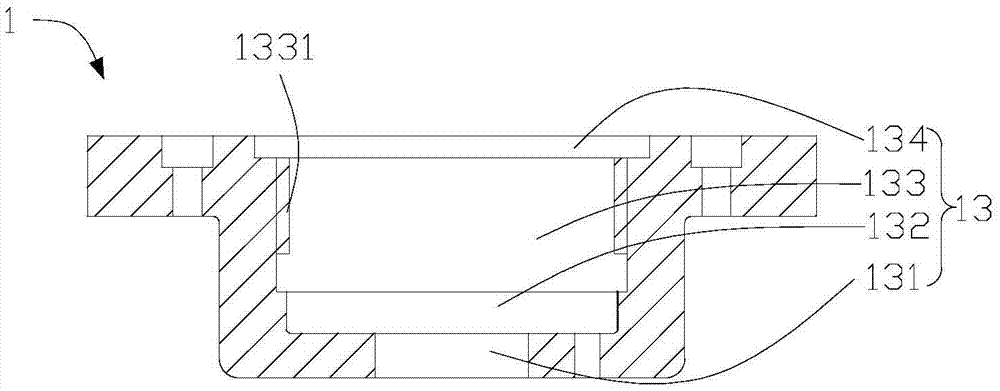

[0026] refer to figure 2 as well as image 3 As shown, the carrier 1 includes a cylindrical base 12 , a rectangular mounting portion 11 disposed above the base 12 , and a receiving hole 13 extending vertically and passing through. The receiving hole 13 includes a cylindrical first part 131, a cylindrical second part 132 above the first part 131, coaxial with the first part 131 and larger in diameter than the first part 131, above the second part 132, and the second Part 132 is coaxial with a cylindrical third part 133 having a diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com