Bearing-less motor suspension winding fault detection method

A bearingless motor, suspended winding technology, applied in the direction of electrical winding testing, measuring electricity, measuring devices, etc., can solve the problems of high model accuracy requirements, a large amount of training data, and complex calculations, and achieve high safety performance, fast and accurate. Diagnosis and correction, simple and easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

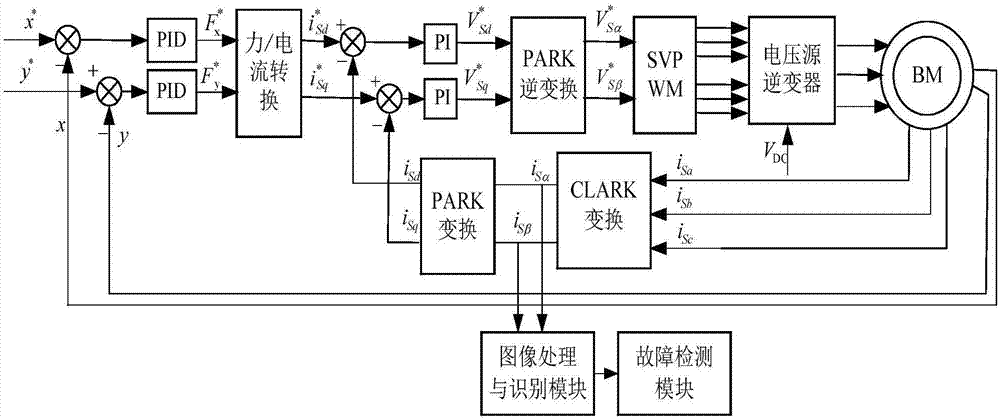

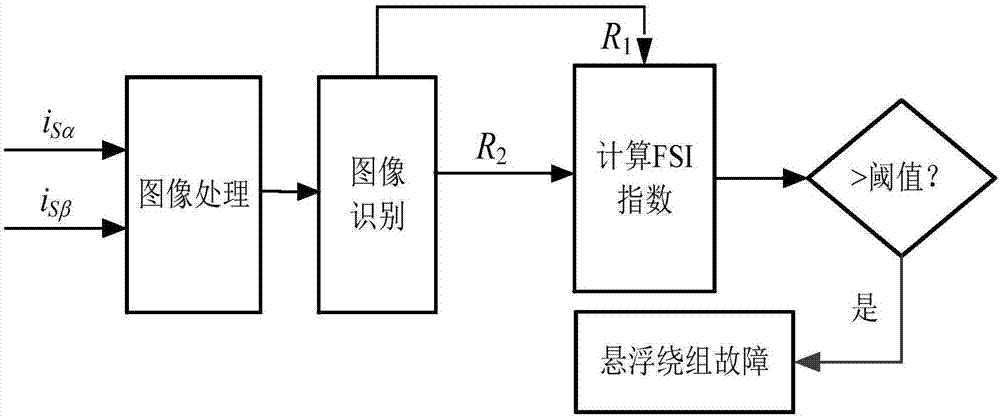

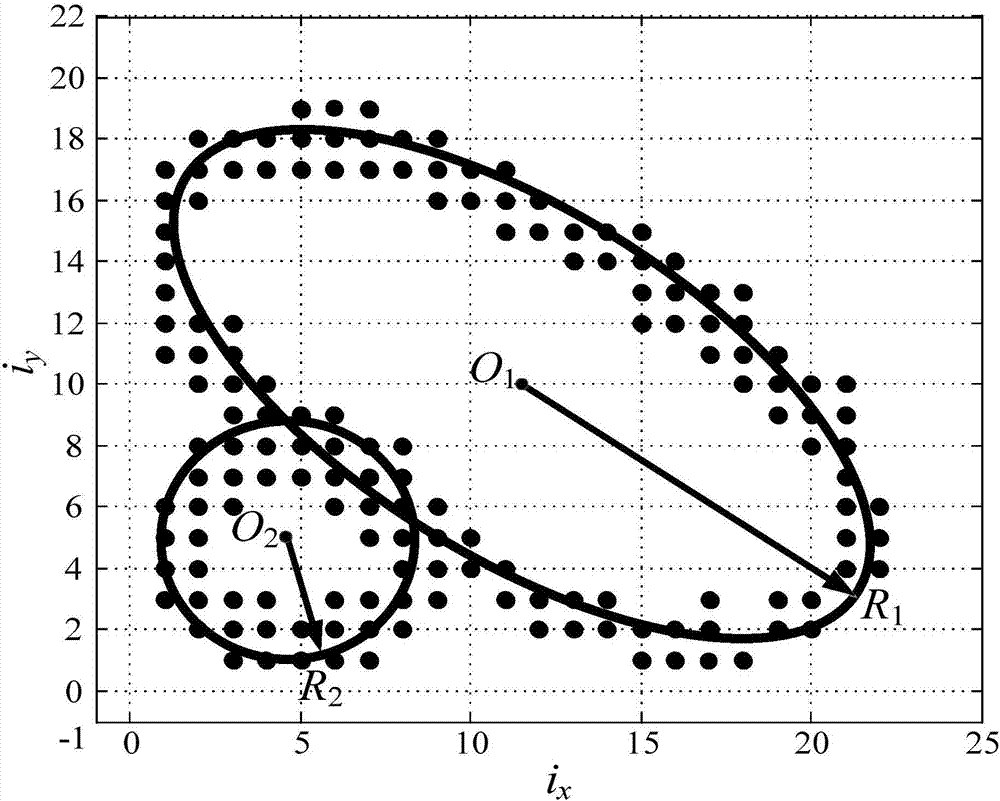

[0013] see figure 1 , the actual radial displacement x, y of the rotor of the bearingless motor (BM) is detected by using the eddy current displacement sensor, and the actual radial displacement x, y is respectively compared with the given radial displacement value x * 、y * For comparison, the two differences of the comparison are respectively input into a position PID regulator, after adjustment, the command values Fx and Fy of the radial suspension force are obtained, and the command values Fx and Fy of the radial suspension force are input into the force / current Conversion module, after force / current conversion, the command value of the winding current in the d-q rotating coordinate system is obtained

[0014] The current sensor is used to detect the suspension winding current of the bearingless motor (BM), and the actual three-phase current i of the suspension winding is obtained Sa i Sb i Sc , the actual suspension winding three-phase current i Sa i Sb i Sc I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com