Reinforced shell manufacturing method and product thereof

A manufacturing method and strong technology, applied in the direction of coating, etc., can solve problems such as gas flow lines, achieve the effects of reducing environmental load, short manufacturing process, and meeting environmental awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

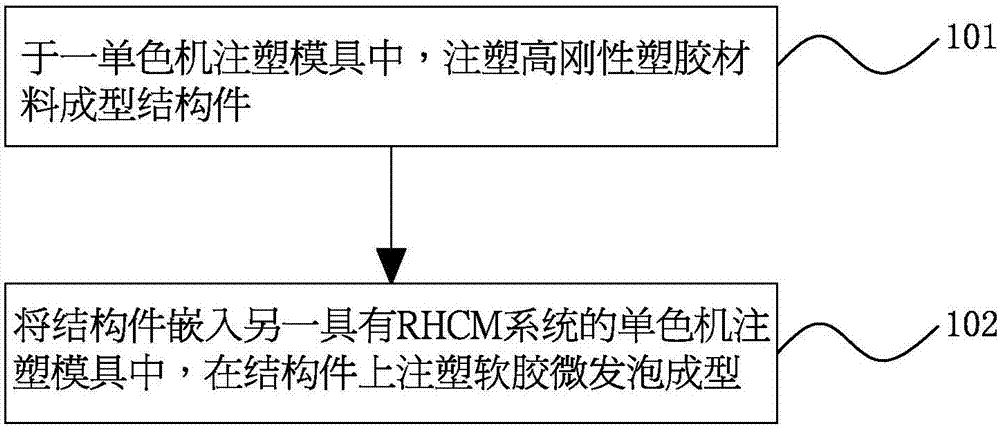

[0031] see figure 1 As shown, it depicts a flow chart of the steps of a preferred embodiment of the manufacturing method of the strong casing of the present invention. In this embodiment 1, the manufacturing method of the strong casing of the present invention includes the following steps:

[0032] Step 101: Injecting high-rigidity plastic material into a structural part in a single-color machine injection mold.

[0033] Step 102: Embedding the structural part into another single-color machine injection mold with the RHCM system, and injecting soft rubber micro-foaming molding on the structural part. The micro-foaming process of the soft rubber is to first pass nitrogen or carbon dioxide through the supercritical fluid control system to generate a supercritical fluid, and then output it to the injection interface, and inject it into the stirring zone of the screw of the injection molding machine through the injection interface, and the molten soft Glue and supercritical flui...

Embodiment 2

[0036] In this embodiment 2, the manufacturing method of the strong casing of the present invention includes the following steps:

[0037] Step 201: In a two-component injection mold equipped with an RHCM system, inject a high-rigidity plastic material micro-foamed structural part. The process of the micro-foamed structural part is to first generate nitrogen or carbon dioxide through a supercritical fluid control system The supercritical fluid is output to the injection interface, and then injected into the stirring zone of the screw of the injection molding machine through the injection interface. The molten high-rigidity plastic material and the supercritical fluid are fully dissolved in the stirring zone to form a single-phase solution, and at a certain constant Keeping it under pressure, when the injection molding machine issues an injection command, the switch nozzle will open and inject the single-phase solution into the cavity of the two-component injection mold with RHC...

Embodiment 3

[0041] Step 301: Injection-molding the micro-foamed structural parts of high-rigidity plastic materials in a single-color machine injection mold with RHCM system, the same principle, the micro-foamed molding method is as described above;

[0042] Step 302: Embedding the structural part into another single-color machine injection mold, and injecting soft rubber on the structural part.

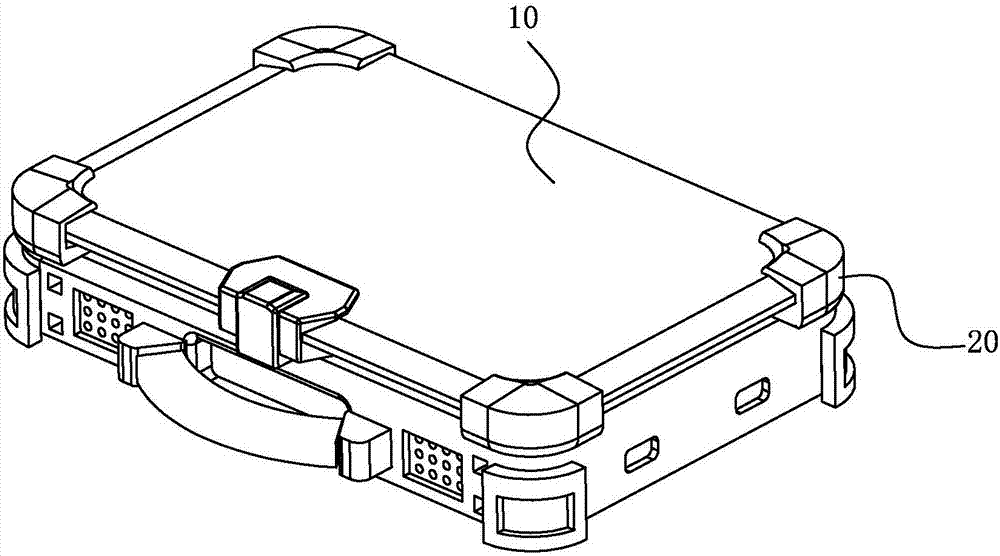

[0043] Therefore, when injecting high-rigidity plastic materials, RHCM combined with micro-foaming molding is used for injection molding to obtain an appearance without air marks, which can be used directly as appearance parts, and the obtained products are both light and strong, and beautiful in appearance. Through the overall structural design , The overall weight of the product can be reduced by 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com