An Optimal Economic Batching and Intelligent Control Model for lf Refining Furnace

An optimal economical and intelligent control technology, applied in the direction of energy efficiency improvement, design optimization/simulation, process efficiency improvement, etc., can solve the problems of reduced molten steel quality, unavoidable heat dissipation loss, and increased labor intensity of temperature measurement operators. , to achieve the effect of low power consumption per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

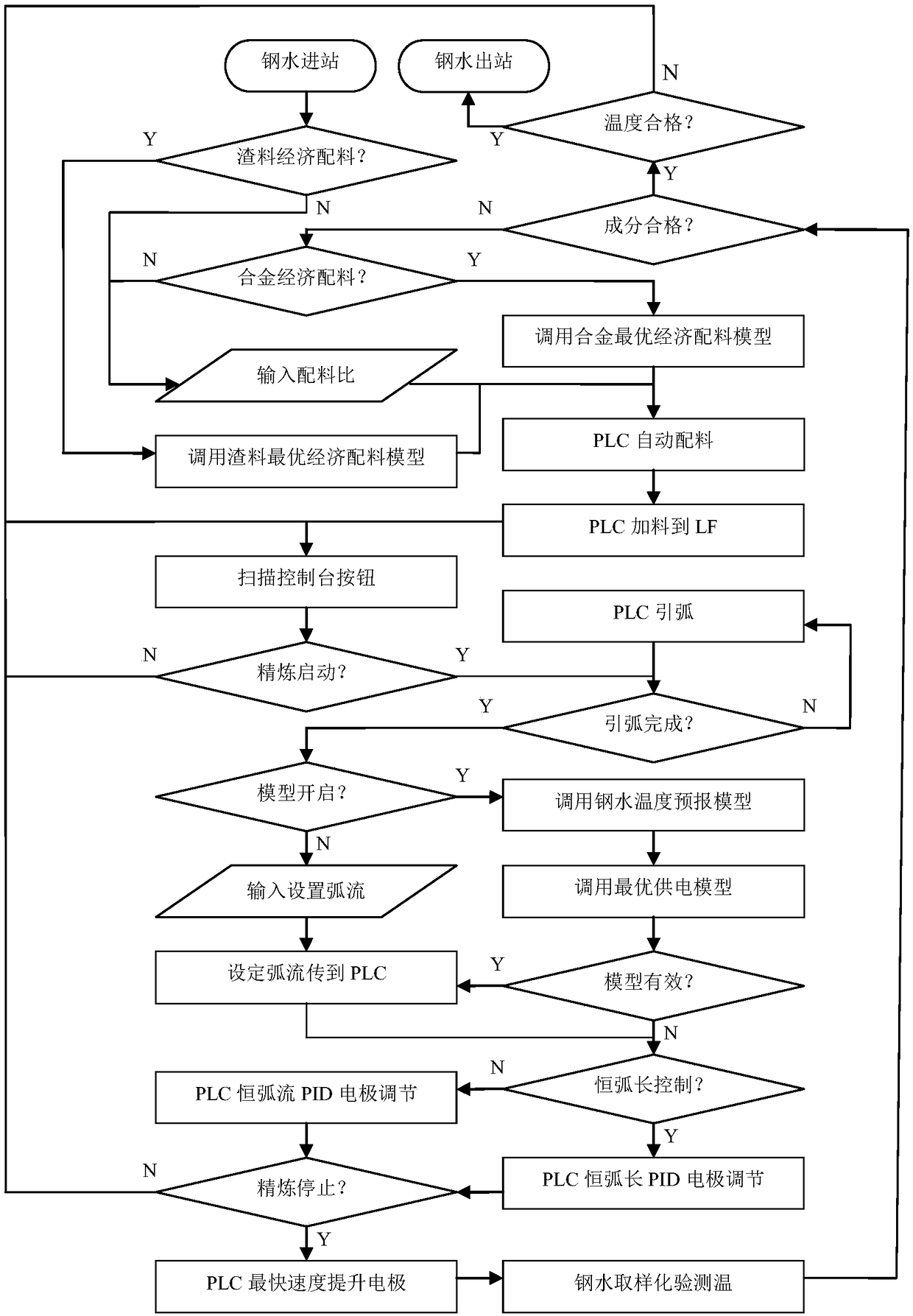

[0231] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

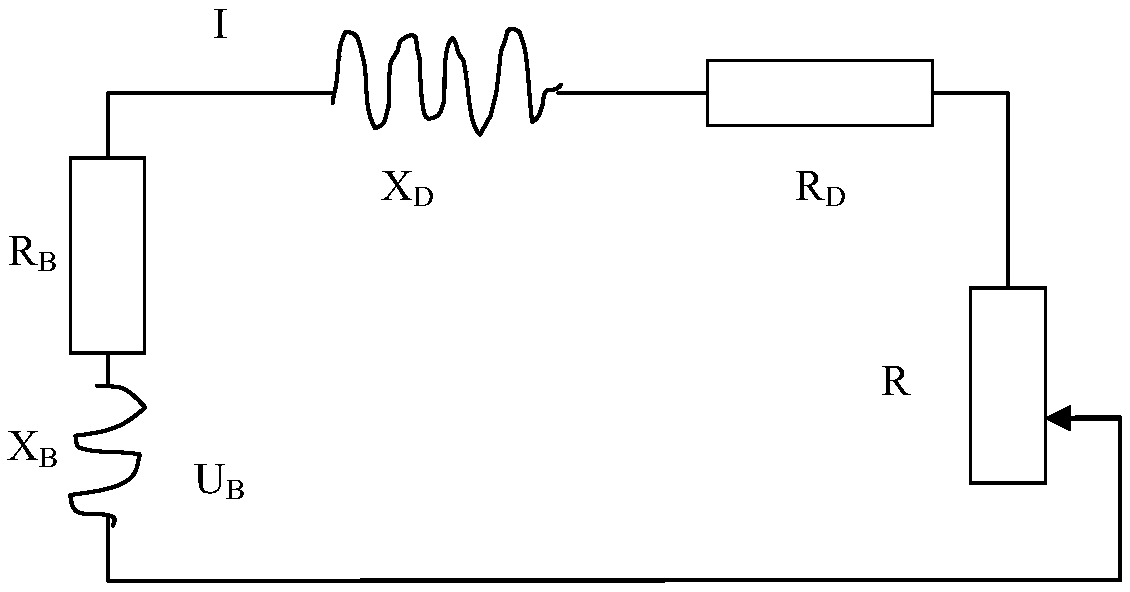

[0232] An LF refining furnace optimal economic batching and intelligent control model, including LF furnace optimal economic batching model and LF furnace molten steel temperature forecast and optimal power supply model;

[0233] One, the optimal economic batching model process of the LF furnace is as follows:

[0234] First, explain the parameters used in the formula:

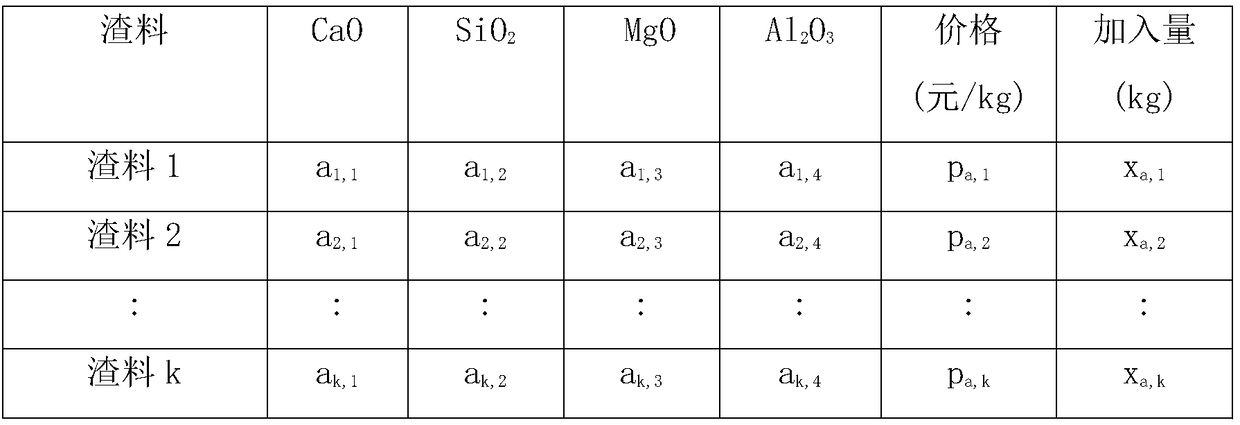

[0235] The chemical composition, price and addition amount of LF slag material are shown in Table 1; the chemical composition and price of slag material are known quantities, and the addition amount is unknown quantity to be sought;

[0236] Table 1 Chemical composition and price of slag

[0237]

[0238] The chemical composition, price and addition amount of LF furnace alloy (including feeding wire) are shown in Table 2; the chemical composition and price of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com