Active control system and control method for pressure of hydraulic accumulator

A technology of active control system and hydraulic accumulator, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., so as to avoid the difficulty of release and improve the energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

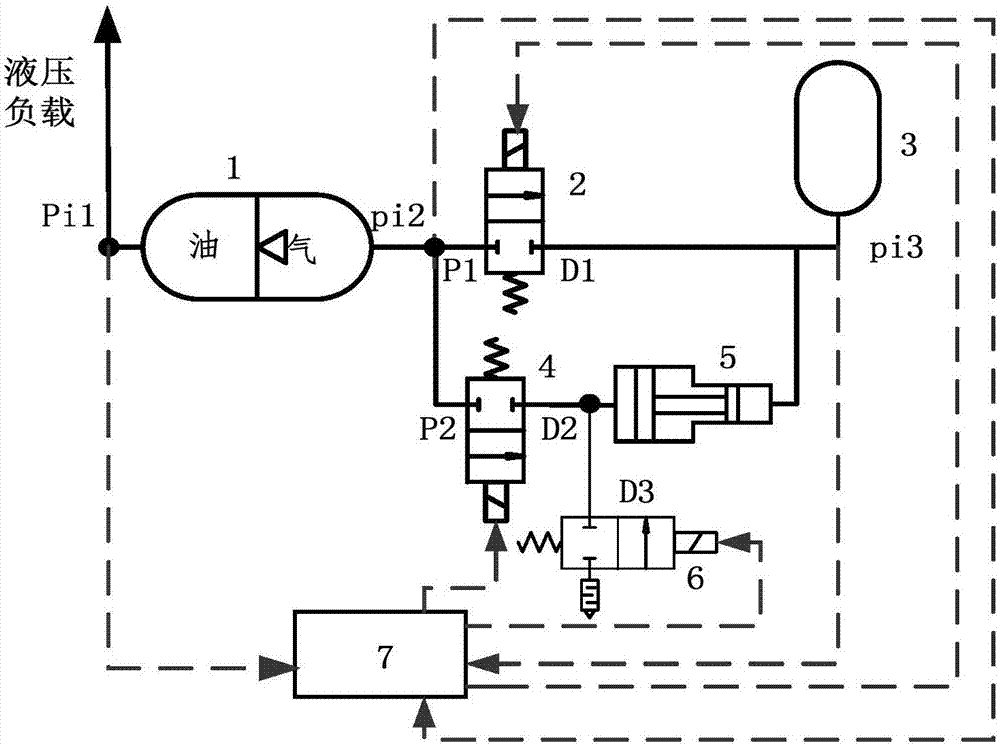

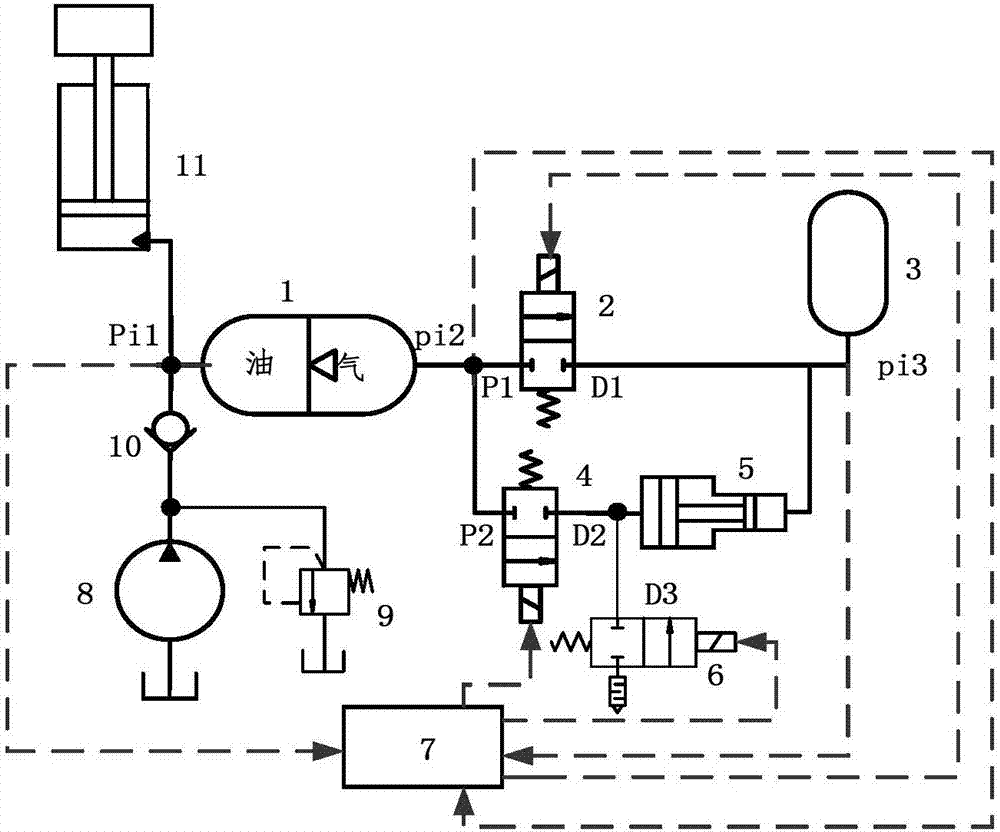

[0026] refer to figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a hydraulic accumulator (1), a first high-speed switch valve (2), a gas cylinder (3), a second high-speed switch valve (4), booster cylinder (5), two-position two-way pneumatic reversing valve (6), controller (7), quantitative pump (8), overflow valve (9), one-way valve (10), mechanical Arm hydraulic cylinder (11); where:

[0027] The hydraulic accumulator (1) includes a cavity, one side inside the cavity is a retractable air bag cavity, and the rest of the cavity outside the air bag cavity is an oil cavity.

[0028] The oil chamber of the hydraulic accumulator (1) is connected with the rodless chamber of the mechanical arm hydraulic cylinder (11) and the one-way valve (10); the oil inlet of the one-way valve (10) is connected with the oil outlet of the quantitative pump (8), The oil inlet port of the overflow valve (9) is connected; the oil out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com