Tubular motor remote controller

A tubular motor and remote control technology, applied in instruments, non-electrical signal transmission systems, signal transmission systems, etc., can solve the problems of confusing remote control, large space occupation, difficult wiring of remote control button circuits, etc., and reduce the number of buttons. The effect of counting, saving internal space, and accurate setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

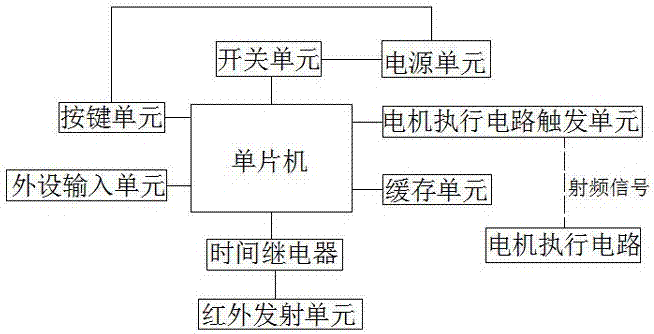

[0013] Such as figure 1 A tubular motor remote control shown includes a single-chip microcomputer, a key unit connected to the single-chip microcomputer, a peripheral input unit, a time relay, a buffer unit, a motor execution circuit trigger unit, and a switch unit, and the switch unit is also connected to a power supply unit , the time relay is also connected to an infrared emission unit; the key unit is a circuit for controlling four-way switches with one key, and has a display light; the trigger unit of the motor execution circuit can emit trigger signals of different frequencies, and the corresponding motor executes The circuit is provided with a receiving unit capable of receiving corresponding frequency signals, and the receiving unit is used to control the on-off of the normally open switches connected in series with the execution circuits of each motor;

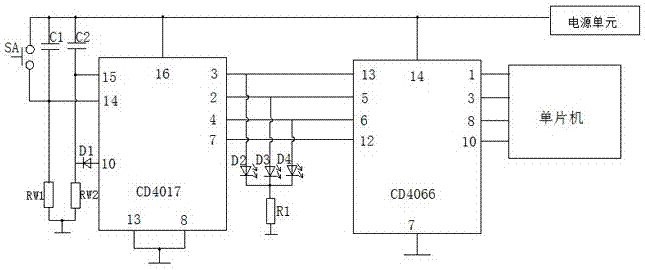

[0014] Such as figure 2 The key unit shown includes a key SA, a pulse distributor CD4017, four bidirectional anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com